Non-knife-mark die cutting method for polyimide film product and die cutting device

A polyimide film and die-cutting technology, which is applied in metal processing and other directions, can solve the problems that the polyimide film cannot be peeled off, the size of the polyimide film is small, and the difficulty is large, so as to facilitate automatic lamination and guarantee Product integrity, the effect of reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

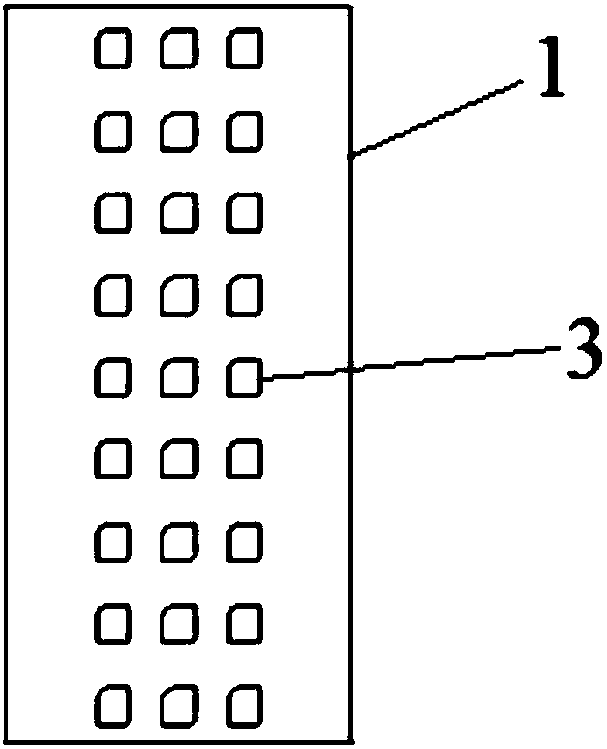

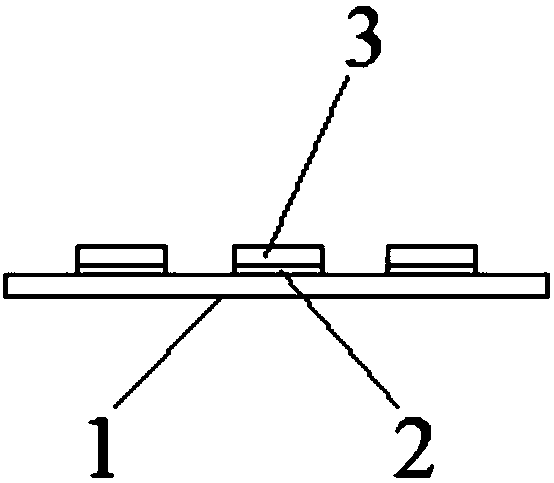

[0052] A kind of non-knife printing die-cutting method of polyimide film product, such as figure 1 , figure 2 Shown, polyimide film product comprises release film material band 1, a plurality of polyimide films 3 and is arranged on the double-sided adhesive tape 2 between polyimide film 3 and release film material band 1, mold The cutting method specifically includes the following steps:

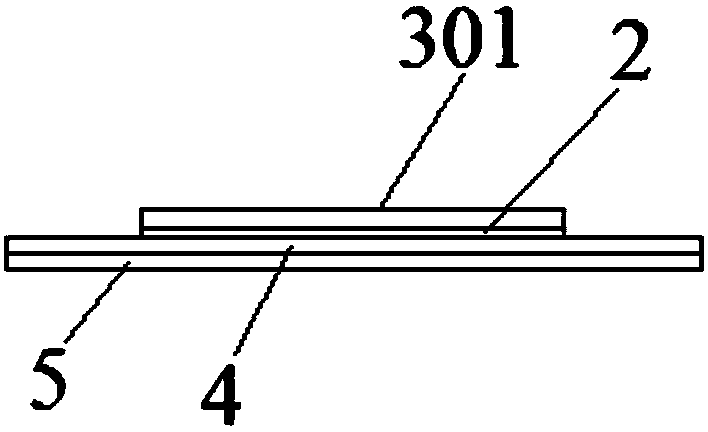

[0053] 1) if image 3 As shown, the polyimide film strip 301 is attached to the auxiliary strip, the auxiliary strip includes the first protective film 5 and the auxiliary release film 4 attached to the first protective film 5, double-sided adhesive tape 2 It is located between the polyimide film strip 301 and the auxiliary release film 4 . Such as Figure 4 As shown, the polyimide film 3 is die-cut on the polyimide film strip 301; a pair of word lines 7 are die-cut on the auxiliary release film 4 at the same time, and the word line 7 is along the auxiliary release film 4. The length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com