Fixing fixture for processing K-wire

A technology for fixing fixtures and Kirschner wires, which is used in manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of increased drilling temperature, damaged bone cells, and difficult to discharge, and achieves improved efficiency and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

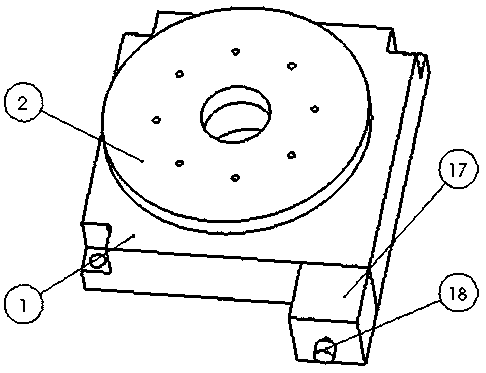

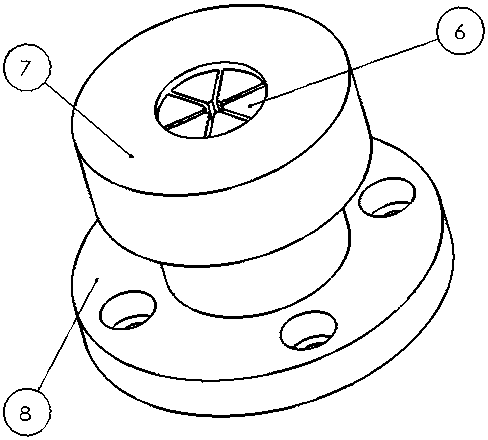

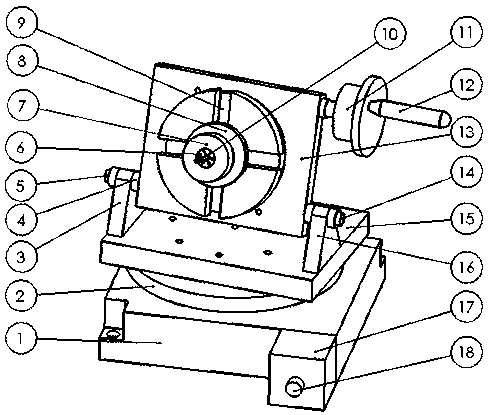

[0016] A fixed fixture for Kirschner wire processing designed in this paper mainly includes: a tiltable rotary table and a horizontal rotary table and workpieces, and is characterized in that the tiltable rotary table mainly includes: an indexing plate (11), a rocker Wheel (12), Rotary Indexer (9), Nut Support (8), Nut (7), Spring Collet (6), Left Adjusting Screw (5), Right Adjusting Screw (14), Pitch Dial ( 4), left bracket (3), right bracket (16), pitch base plate (13), and base plate (15); the horizontal rotary table mainly includes: base (1), dial (2), motor (17) and Motor nut (18); workpiece: Kirschner wire (10).

[0017] Concrete work process of the present invention is:

[0018] The Kirschner wire is clamped and fixed, and the Kirschner wire is processed to mainly realize movement in three directions:

[0019] 1. Pitching motion in the vertical direction: adjust the left adjusting screw (5) and the right adjusting screw (14), and through the pitching dial (4), precise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com