Electric vehicle body machining process and special grinding tool

A processing technology, electric vehicle technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problems that affect the aesthetics of the frame, and achieve the effect of enhanced protection, reduced joints, and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

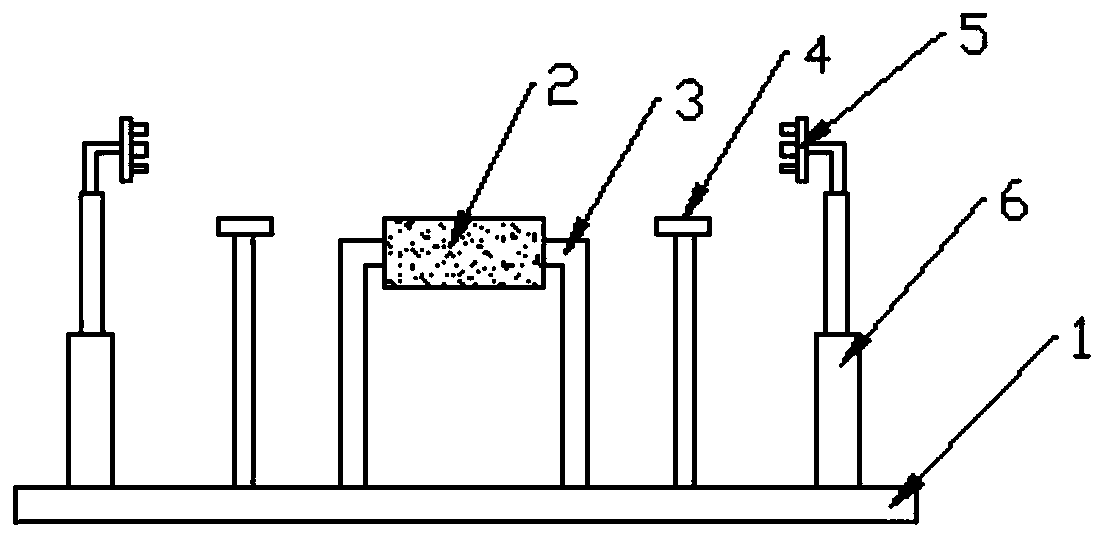

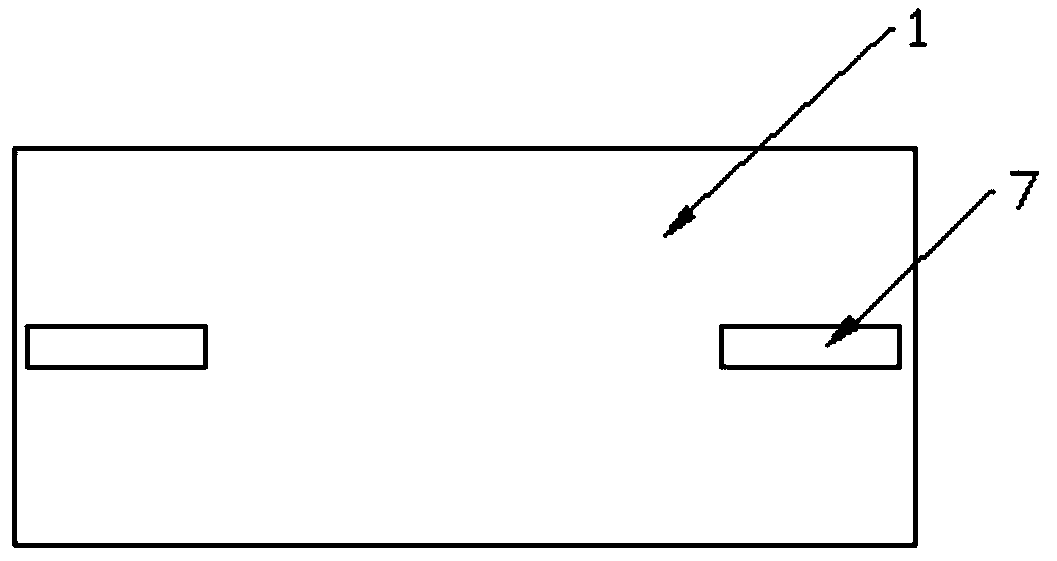

[0048] On the one hand, this embodiment provides a process for processing an electric vehicle body, including the following steps:

[0049] Cutting: cut the pipe and plate according to the processing size to obtain the sheet metal blank;

[0050] Forming: Stamping and bending the sheet metal blank to obtain frame accessories;

[0051] Welding: Welding and connecting the frame parts together to form the car body;

[0052] Grinding: Grinding and smoothing the connection points on the car body;

[0053] Spraying: spraying paint on the surface of the car body;

[0054] Drying: Let the paint dry.

[0055] In this embodiment, the spraying is a spraying primer, and after drying, the paint is baked. Baking paint not only improves the aesthetics, but also enhances the protective effect on the frame and prevents rust.

[0056] In the forming step, the forming of the plate is stretched by a stamping mold, so that the plate is stretched integrally to form the main board and the wall ...

Embodiment 2

[0069] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are: Figure 4 As shown, in this embodiment, the caliper 4 adopts an arc-shaped surface, which can be more conveniently adapted to circular pipes. When the caliper 4 is an arc-shaped surface, Figure 4 The lowest point of the shown inner surface is on the level of the surface of the grinding wheel 2, so as to ensure that the surface of the polished pipe is smooth.

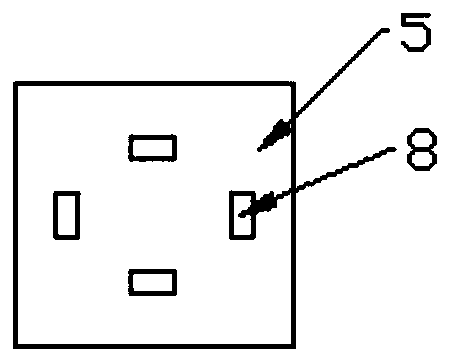

[0070] Such as Figure 5 As shown, the clamp of this embodiment adopts claws 8, the middle part of the clamping surface of the claws 8 is arc-shaped, and the two sides are planes. The jaws 8 of this embodiment can make the arc-shaped surface of the middle part contact with the surface of the pipe when clamping a circular pipe, and can make the planes on both sides contact with the pipe when clamping a square pipe, and the contact are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com