A kind of highly stable palladium-nickel carbon catalyst catalyzes the method for synthesizing vitamin E intermediate

A technology of carbon catalysts and vitamins, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and preparation of organic compounds, etc. It can solve the problems of poor catalytic activity and selectivity, poor recovery of catalysts, and poor performance of catalyst recycling. Achieve the effects of avoiding competitive adsorption, improving anti-toxicity performance, and improving application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

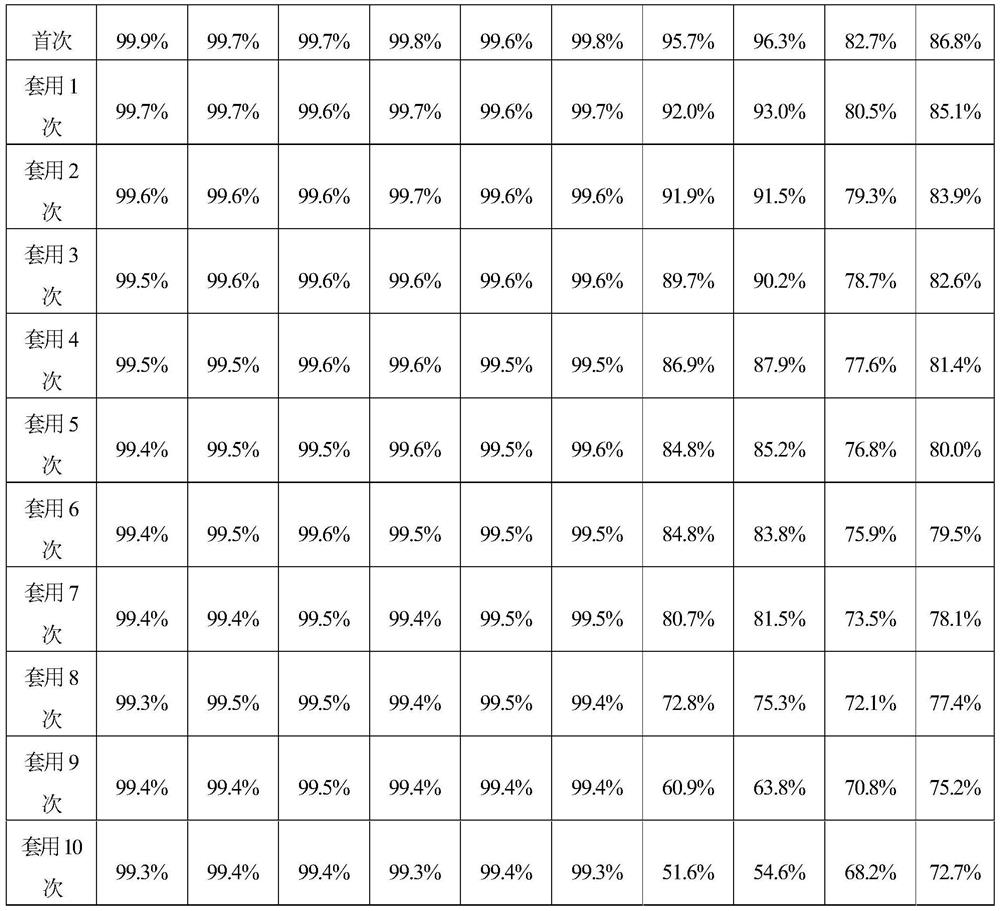

Embodiment 1

[0023] 1. Add 100g of powdered activated carbon with a particle size of 200 to 400 meshes into 1000mL 5mol / L urea aqueous solution and soak for 6 hours, centrifuge in a centrifuge to remove excess urea aqueous solution in the carbon slurry, and then place the precipitate in an oven to dry at 80 °C for 10 hours to constant weight, and then cured at 650 °C for 4 h in a nitrogen atmosphere to obtain pretreated activated carbon.

[0024] 2. Dissolve 4.24g of nickel acetate in 200mL of deionized water, and stir evenly to obtain a nickel precursor solution; add 94.5g of pretreated activated carbon into the nickel precursor solution, soak for 4 hours under stirring conditions, and then add sodium hydroxide to adjust The pH of the impregnation system is 8.5, continue to stir for 2 hours and then filter, wash the filter cake with deionized water until neutral, dry it in an oven at 80°C to constant weight, and then activate it in a hydrogen atmosphere at 800°C for 3 hours to obtain activ...

Embodiment 2

[0028] 1. Add 100g of powdered activated carbon with a particle size of 200 to 400 mesh and soak in 800mL of 6mol / L urea aqueous solution for 4 hours, centrifuge in a centrifuge to remove excess urea aqueous solution in the carbon slurry, and then place the precipitate in an oven to dry at 80 °C for 8 hours to constant weight, and then cured at 680 °C for 4 hours in a nitrogen atmosphere to obtain pretreated activated carbon.

[0029] 2. Dissolve 8.48g of nickel acetate in 200mL of deionized water, and stir evenly to obtain a nickel precursor solution; add 93g of pretreated activated carbon to the nickel precursor solution, soak for 4.5h under stirring conditions, and then add sodium carbonate to adjust the impregnation The pH of the system is 8.5, continue to stir for 3 hours and then filter, wash the filter cake with deionized water until neutral, dry it in an oven at 80°C to constant weight, and then activate it in a hydrogen atmosphere at 600°C for 2.5h to obtain activated ...

Embodiment 3

[0033]1. Add 100g of powdered activated carbon with a particle size of 200 to 400 mesh into 1200mL 4mol / L urea aqueous solution and soak for 7 hours, centrifuge in a centrifuge to remove excess urea aqueous solution in the carbon slurry, and then place the precipitate in an oven to dry at 80 °C for 9 hours to constant weight, and then cured at 600 °C for 4 hours in a nitrogen atmosphere to obtain pretreated activated carbon.

[0034] 2. Dissolve 12.387g of nickel nitrate in 200mL of deionized water, and stir evenly to obtain a nickel precursor solution; add 92.5g of pretreated activated carbon into the nickel precursor solution, soak for 4 hours under stirring conditions, and then add sodium bicarbonate to adjust The pH of the impregnation system is 10, continue to stir for 4 hours and then filter, wash the filter cake with deionized water until neutral, dry it in an oven at 80°C to constant weight, and then activate it in a hydrogen atmosphere at 500°C for 3.5h to obtain Acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com