Preparation method of Cu/TiO2 catalyst

A catalyst and reducing agent technology, applied in the field of catalyst preparation, can solve the problem of uneven surface distribution, achieve high catalytic activity, achieve precise control, and high shape retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

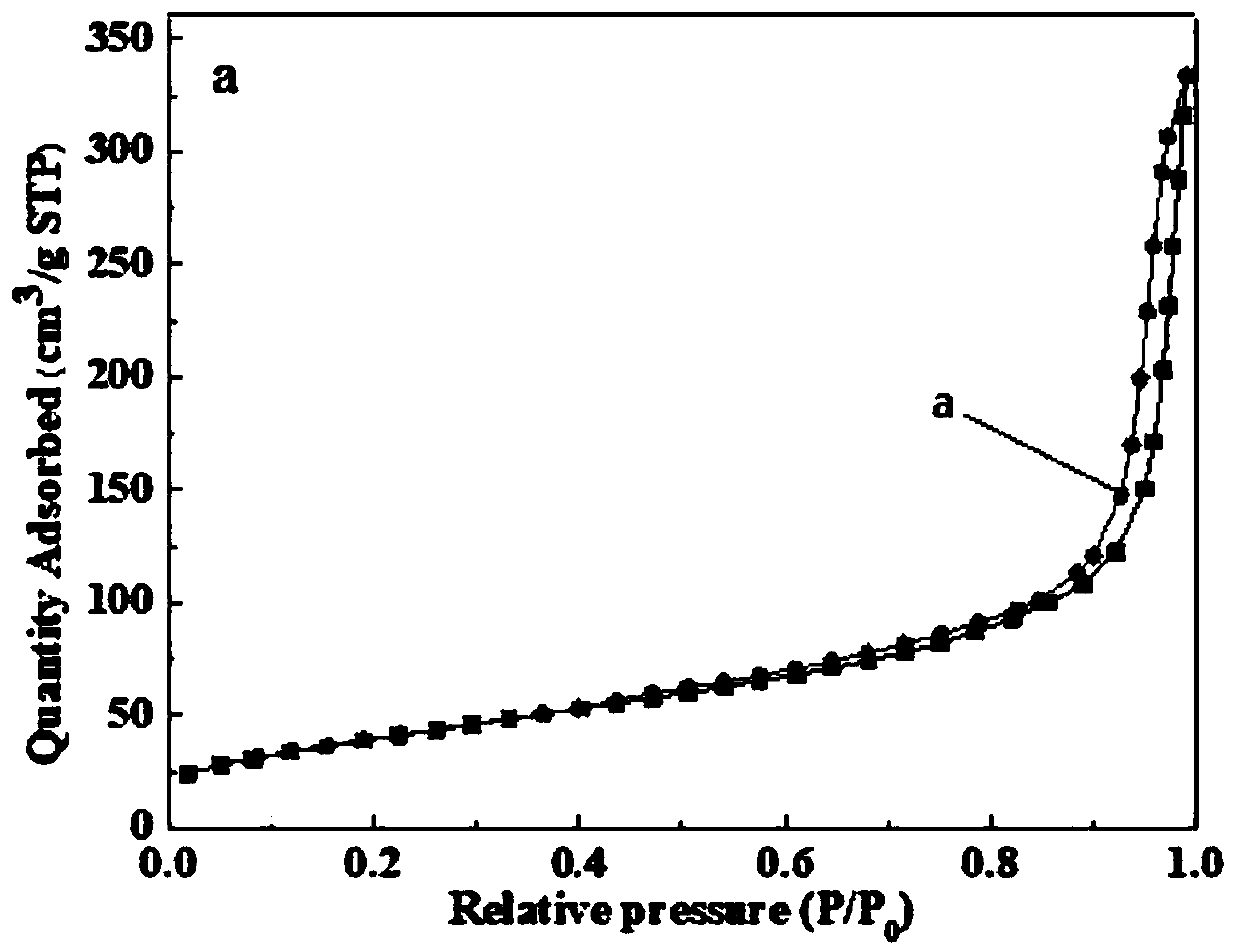

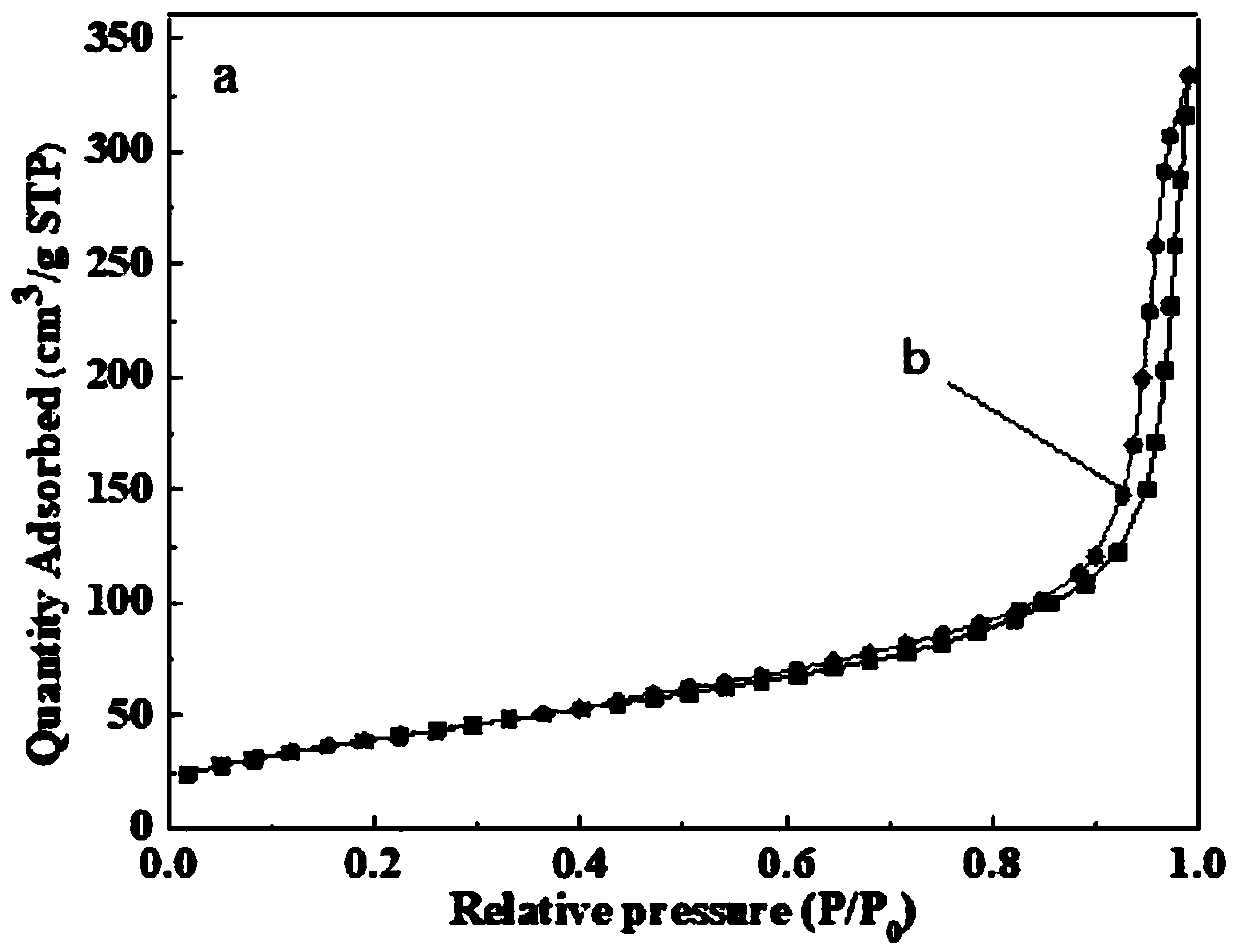

Image

Examples

Embodiment 1

[0037] This embodiment prepares Cu / TiO 2 (TiO 2 Particle diameter is 10nm) the step of catalyst is as follows:

[0038] (1) Enter the vaporized copper precursor into the gas phase adsorption system in the form of pulse, the pulse time is 12s, so that the copper precursor is adsorbed on the nano-TiO 2 surface;

[0039] (2) Nitrogen gas is filled into the system for purging, and the unadsorbed precursor and by-products in the system are removed from the system. Among them, N 2 The purging treatment time is 20s, the nitrogen flow rate is 180mL / min, and the system pressure is maintained at 4×10 3 Pa;

[0040] (3) Introduce hydrogen into the system, the flow rate is 180mL / min, the inflation time is 500ms, and the system pressure is maintained at 4×10 3 Pa, will be adsorbed on nano-TiO 2 The precursor on the surface is reduced to copper;

[0041] (4) Nitrogen is passed into the system, and the excess H 2 and by-products are removed from the system, where N 2The purging tre...

Embodiment 2

[0045] This embodiment prepares Cu / TiO 2 (TiO 2 Particle diameter is the step of 100nm) catalyst as follows:

[0046] (1) Put the gasified copper precursor into the gas phase adsorption system in the form of pulse, the pulse time is 6s, so that the copper precursor is adsorbed on the nano-TiO 2 surface;

[0047] (2) Nitrogen gas is filled into the system for purging, and the unadsorbed precursor and by-products in the system are removed from the system. Among them, N 2 The purge treatment time is 10s, the nitrogen flow rate is 150mL / min, and the system pressure is maintained at 3×10 3 Pa;

[0048] (3) Introduce NH into the system 3 , the flow rate is 150mL / min, the inflation time is 300ms, and the system pressure is maintained at 3×10 3 Pa, will be adsorbed on nano-TiO 2 The precursor on the surface is reduced to copper;

[0049] (4) Nitrogen is passed into the system, and the excess NH 3 and by-products are removed from the system, where N 2 The purging treatment t...

Embodiment 3

[0053] This embodiment prepares Cu / TiO 2 (TiO 2 Particle diameter is the step of 50nm) catalyst as follows:

[0054] (1) Enter the vaporized copper precursor into the gas phase adsorption system in the form of pulse, the pulse time is 8s, so that the copper precursor is adsorbed on the nano-TiO 2 surface;

[0055] (2) Nitrogen gas is filled into the system for purging, and the unadsorbed precursor and by-products in the system are removed from the system. Among them, N 2 The purge treatment time is 15s, the nitrogen flow rate is 200mL / min, and the system pressure is maintained at 6×10 3 Pa;

[0056] (3) Pass hydrazine vapor into the system, the flow rate is 200mL / min, the inflation time is 400ms, and the system pressure is maintained at 6×10 3 Pa, will be adsorbed on nano-TiO 2 The precursor on the surface is reduced to copper;

[0057] (4) Nitrogen is passed into the system, and the excess NH 3 and by-products are removed from the system, where N 2 The purge treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com