Three-dimensional channeled fabric structure for garments and/or footwear

A fabric structure and three-dimensional channel technology, applied in clothing, clothing, footwear, etc., can solve the problems of clothing condensation, not allowing steam to be discharged, and complex clothing structure, and achieve the effect of enhancing shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In the following embodiment examples, various features given with respect to specific examples may actually be interchanged with other different features existing in other embodiments or examples.

[0070] 7, a prior art spacer fabric 300, such as that described in US Patent No. 6,156,406 issued to MMI-IPCO, LLC (the entire disclosure of which is incorporated herein by reference), includes a fabric made of stitching yarn 170 The first fabric layer 130 is formed, the second fabric layer 150 made of stitching yarns 190, and the pile yarn 210 that interconnects the two layers. In addition, the knitted spacer fabric 110 includes the inner weave yarn 250 or the inlay yarn 260 held by the stitching yarns 170 and 190, respectively, as shown.

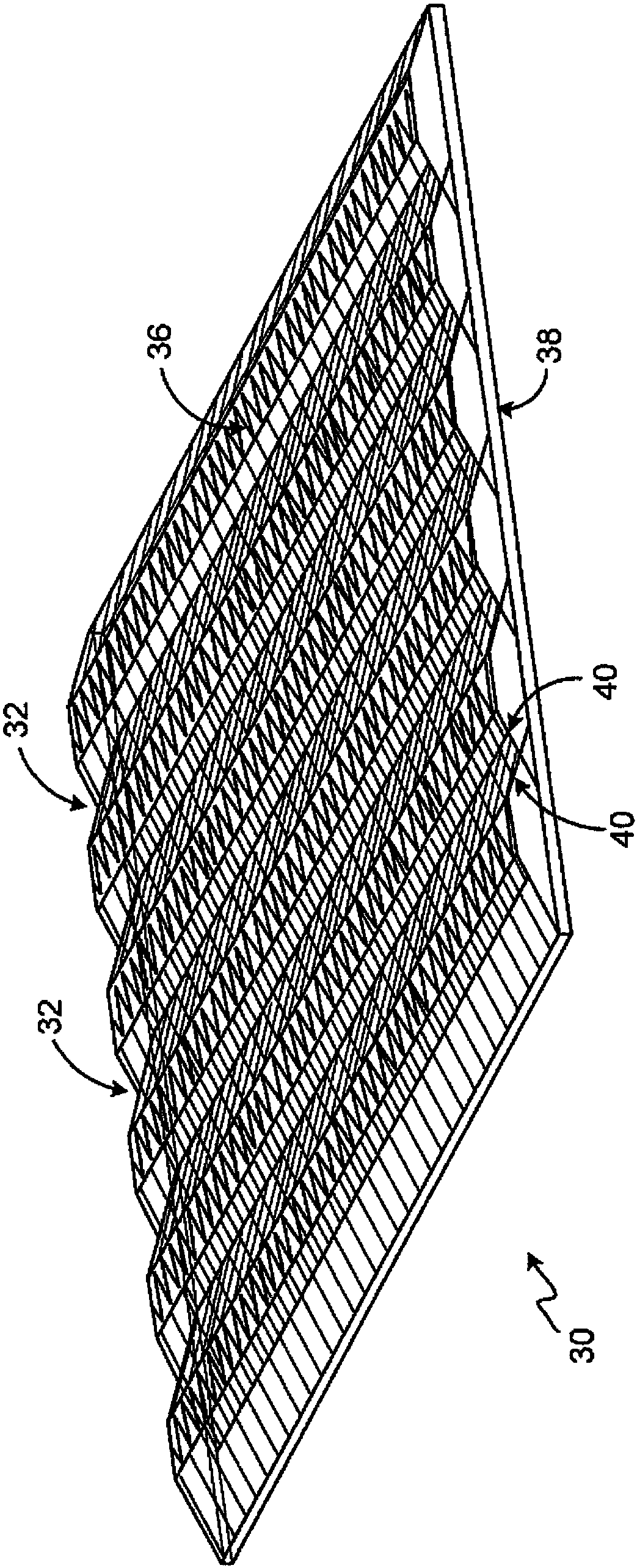

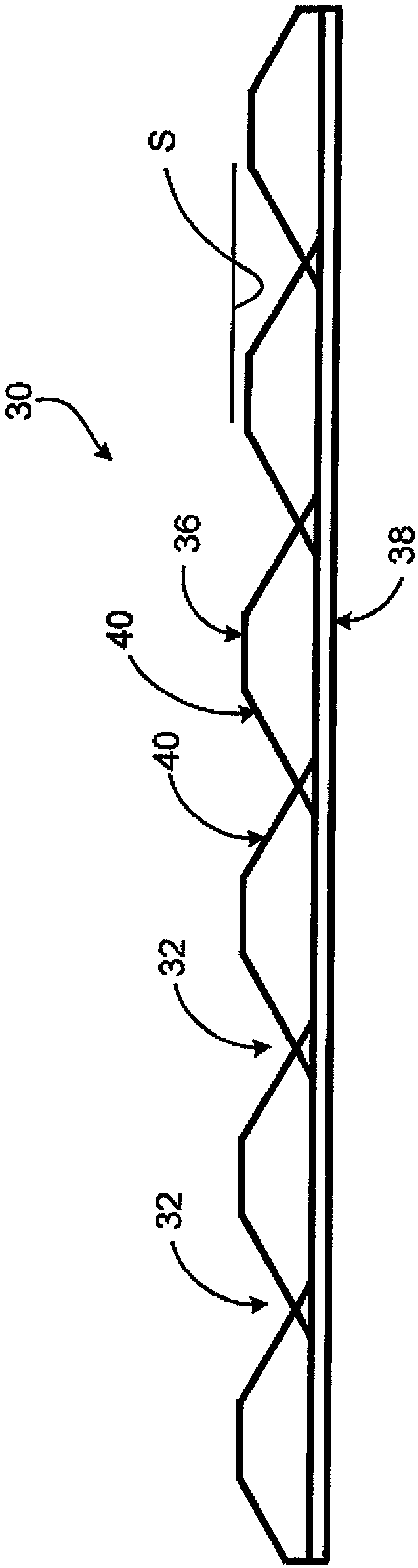

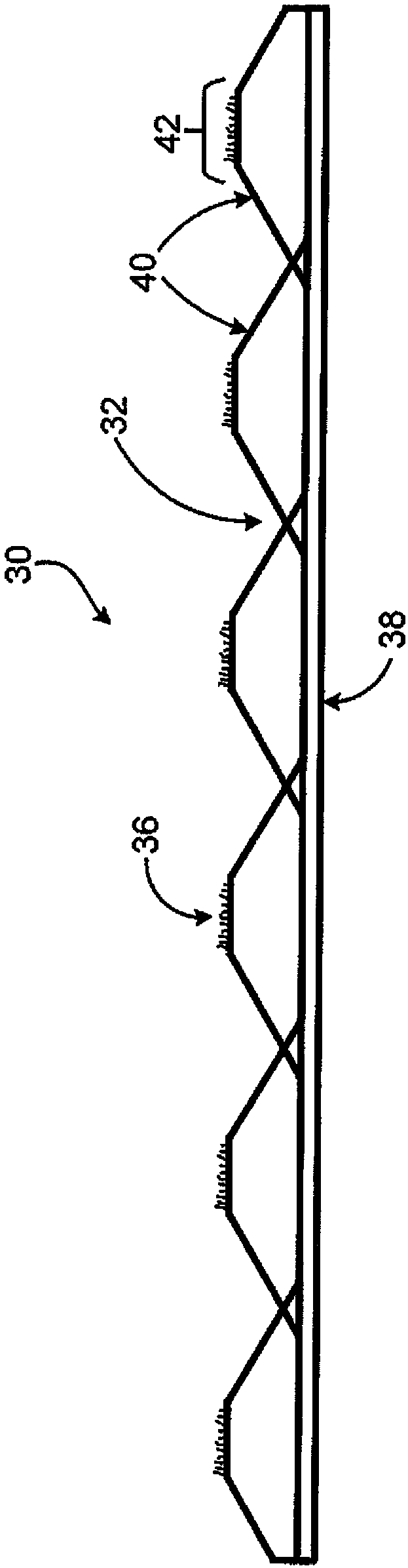

[0071] The disclosed embodiments relate to three-dimensional fabric structures. The three-dimensional fabric can be obtained using a 2D or 3D type weaving process or any other process known to those of ordinary skill in the art. Specificall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com