PBT(polybutylene terephthalate) esterification reaction system

A technology of esterification reaction and esterification reaction kettle, applied in the field of PBT production system and PBT esterification reaction system, can solve the problems of occupying upper chamber space, waste of raw materials, and high reaction pressure, and achieve the effect of easy transportation and avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

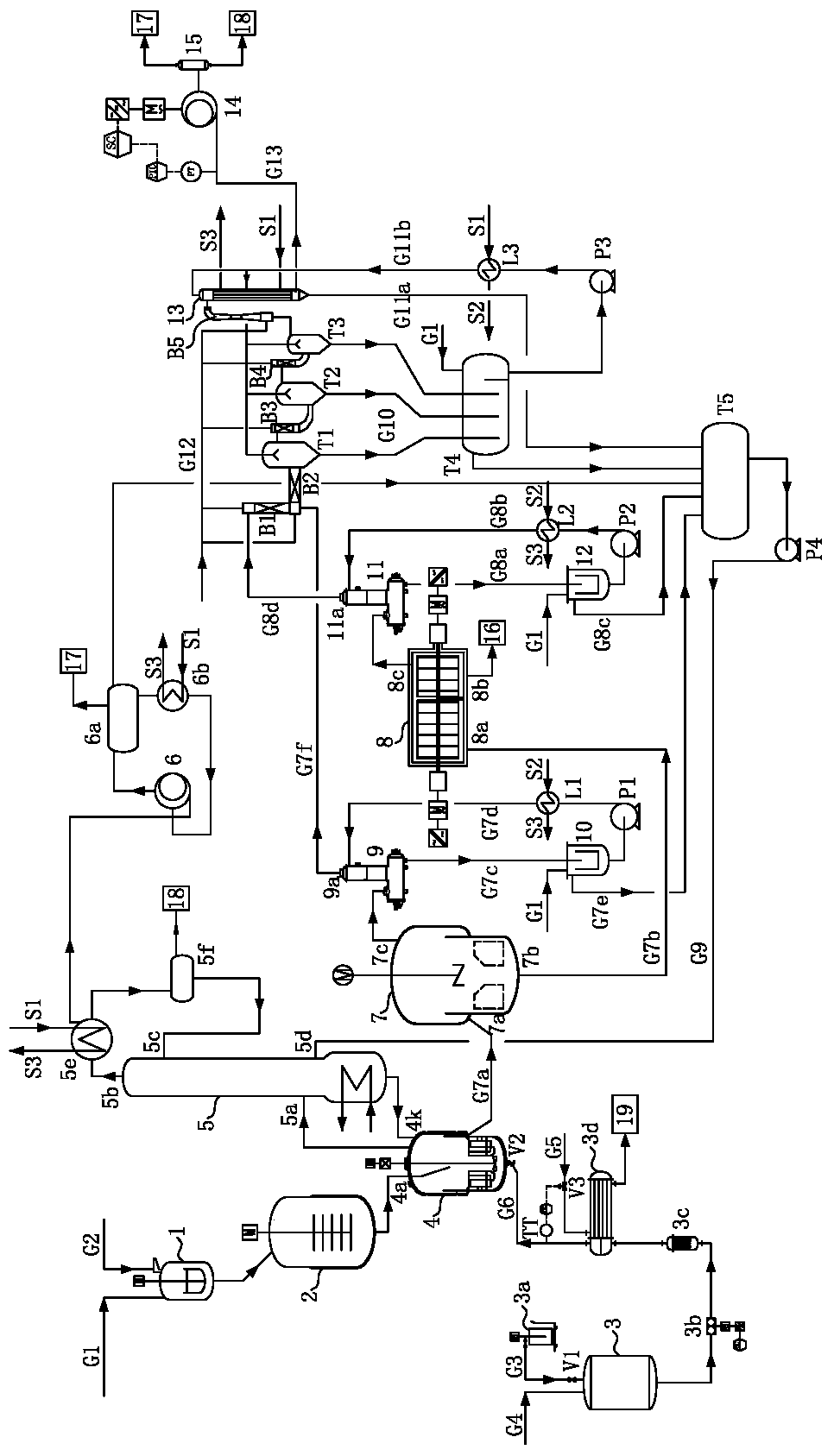

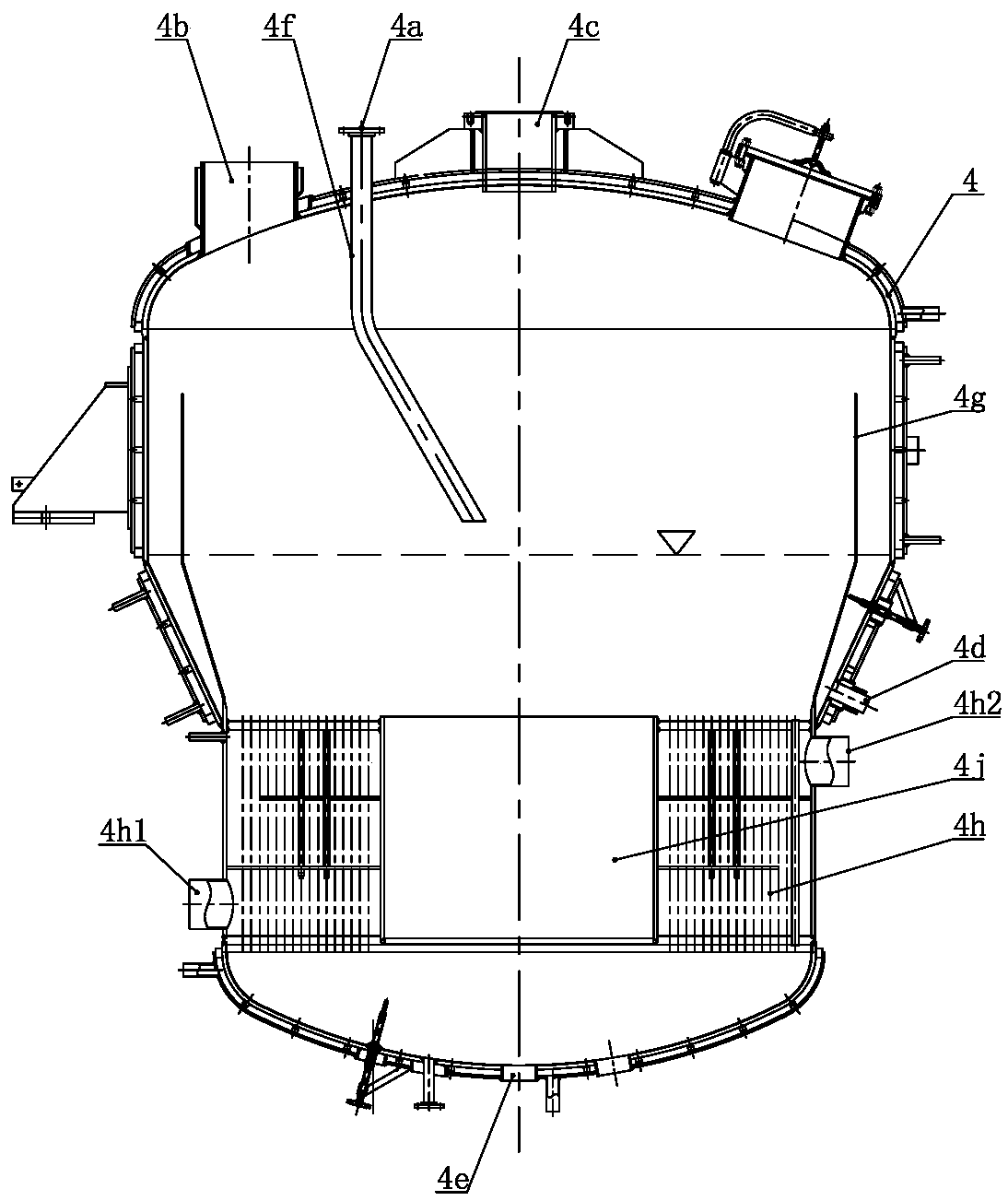

[0034] Such as Figure 1 to Figure 7 As shown, the PBT esterification reaction system of the present invention includes a slurry preparation tank 1 , a slurry finished product tank 2 , a catalyst tank 3 , an esterification reactor 4 , a precondensation reactor 7 and a final polycondensation reactor 8 . The discharge port at the bottom of the slurry product tank 2 is connected to the esterification tank slurry inlet 4a at the top of the esterification reactor 4, and the esterification tank outlet 4d in the middle of the esterification reactor 4 passes through the G7a. The feed port 7 a of the pre-condensation reactor 7 is connected, and the outlet 7 b of the pre-condensation reactor 7 is connected with the feed port 8 a of the final polycondensation reactor 8 .

[0035] The top of slurry preparation tank 1 is connected with BDO supply pipe G1 and PTA feed pipe G2. PTA powder is metered by PTA metering system and liquid BDO is continuously added into slurry preparation tank 1 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com