Formaldehyde-free protein adhesive and preparation method thereof

An adhesive and protein glue technology, which is applied in the preparation of protein adhesives, animal glue or gelatin, and adhesives, etc. Solve problems such as formaldehyde release from wood-based panels, and achieve the effect of increasing the number and type, increasing the type and quantity, and good water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

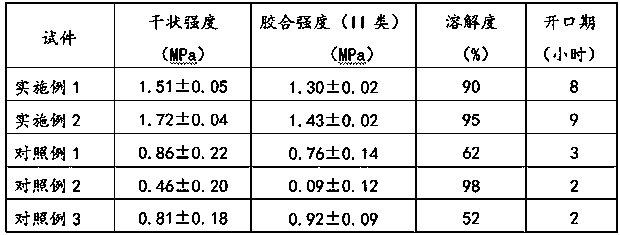

Examples

Embodiment 1

[0040] An aldehyde-free protein adhesive consisting of the following materials by weight:

[0041] Demineralized water 70 kg;

[0042] Defatted soybean meal protein powder 30 kg;

[0043] Trypsin 0.2kg;

[0044] Ficin 0.2kg;

[0046] Triethylenetetramine 0.2kg;

[0047] Ethylene glycol diglycidyl ether 0.5kg.

[0048] When the formaldehyde-free protein adhesive in this embodiment is used: mix the formaldehyde-free protein adhesive, water, methylol, isocyanate, epoxy, and polyurethane cross-linking agent, and stir at room temperature for 10 minutes. Stir well.

Embodiment 2

[0050] An aldehyde-free protein adhesive consisting of the following materials by weight:

[0051] Demineralized water 70 kg;

[0052] Defatted soybean meal protein powder 30 kg;

[0053]Trypsin 0.5kg;

[0054] Ficin 0.5kg;

[0056] Triethylenetetramine 0.5kg;

[0057] Ethylene glycol diglycidyl ether 1kg.

Embodiment 3

[0059] A preparation method of aldehyde-free protein adhesive, comprising the following steps:

[0060] (1) According to the weight ratio in the above-mentioned formaldehyde-free protein adhesive, weigh each component and prepare raw materials;

[0061] (2) Evenly disperse the defatted soybean meal protein powder, water and trypsin in the dispersion medium water, raise the temperature of the water bath to 40°C, and stir for 30 minutes. When the temperature rises to 80°C, keep warm for 10 minutes and then inactivate the enzyme;

[0062] (3) Cool down the mixture obtained in step 2 to 40°C, add ficin, keep it warm for 15 minutes, and heat up to 80°C to inactivate the enzyme;

[0063] (4) Add sodium periodate to the mixture obtained in step 3, raise the temperature to 50°C, adjust the pH value to 4.0, add triethylenetetramine after reacting for 5 hours, react at 50°C for 2 hours, then raise the temperature to 90°C, and react 6 Hour;

[0064] (5) Heat the mixture in step 4 to 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com