Octenyl succinic acid starch ester, lipid-soluble nutrient microcapsule as well as preparation method application of lipid-soluble nutrient microcapsule

A technology of octenyl succinic acid and fat-soluble nutrients, applied in the field of synthetic chemistry, can solve problems such as low degree of substitution, severe local reaction, insoluble acid anhydrides in water, etc., to improve application performance, short production cycle, and improve emulsification. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation of embodiment 1 octenyl starch succinate

[0049] 1) Mixing: Weigh 100Kg of waxy cornstarch and 600Kg of water at room temperature, stir evenly, adjust the pH value to 8.0, and stir evenly.

[0050] 2) Cooking and gelatinization: set the gelatinization temperature at 140°C, feed the material, and gelatinize for 20s (that is, the steam contacts the material for 20s), to obtain gelatinized starch, and turn on the cooling device to cool the material to 40°C.

[0051] 3) Cavitation emulsification: gelatinized starch is poured into the cavitation emulsification feeding bin of the single-stage cavitation emulsification device, 3Kg OSA is added while stirring, and the flow rate is set at 10L / min, the pressure is 500bar, and the cycle is 5 times to obtain An aqueous dispersion of starch octenyl succinate, wherein the mass percent content of starch octenyl succinate is 14.7%.

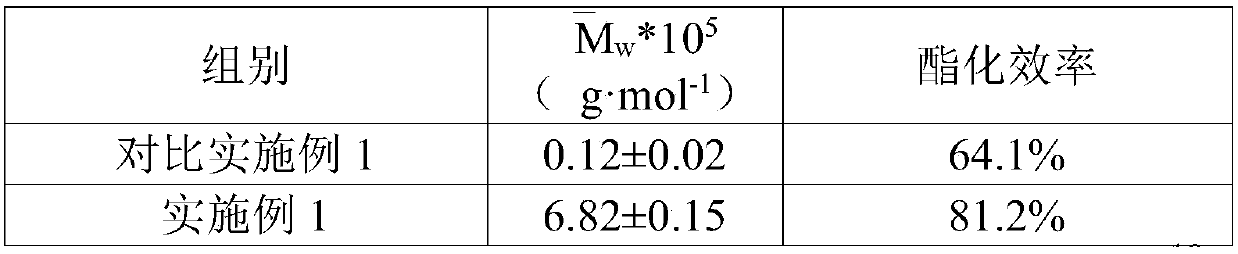

[0052] Comparative example 1 conventional method prepares octenyl succinic acid starc...

Embodiment 2~5

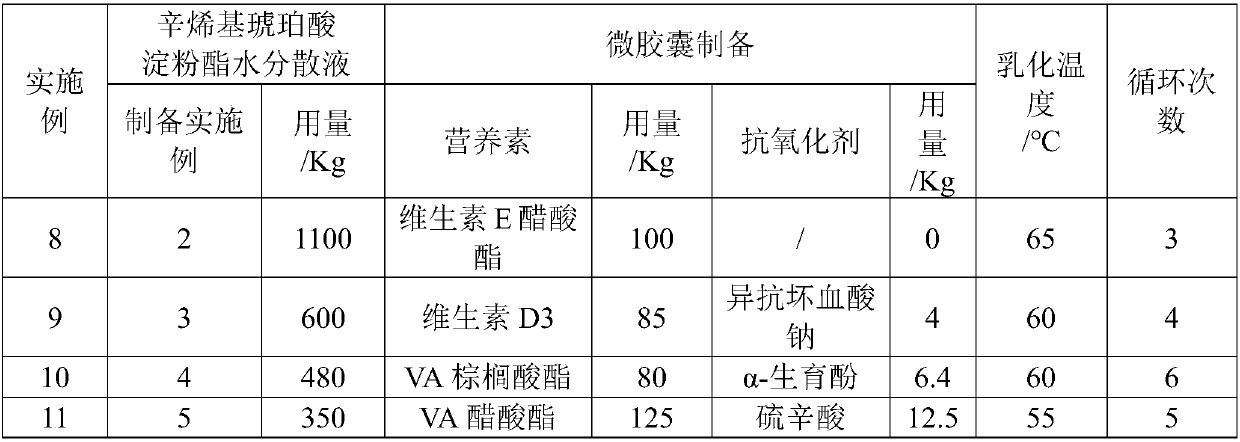

[0064] According to the method of embodiment 1, adjust parameters such as starch type, water consumption, gelatinization temperature and time, pH value, the consumption of octenyl succinic anhydride, the flow rate of cavitation emulsification and pressure and number of cycles, other conditions and Embodiment 1 is identical, obtains result as following table 2: (mass unit: Kg, flow velocity: L / min, pressure: bar)

[0065] Table 2

[0066]

Embodiment 6

[0067] The emulsifying properties of embodiment 6 octenyl starch succinate

[0068] Under room temperature, get the octenyl starch succinate aqueous dispersion (wherein containing 5Kg octenyl starch succinate) and 6KgVE (vitamin E) oil that is made by 100Kg waxy cornstarch and 600Kg water in 34Kg embodiment 1, Add 20Kg of water, high-speed shear (10000r / min) for 5min and high-pressure homogenization (500bar) for 10min to obtain an emulsion. Take 0.5g of the middle part of the emulsion sample into a 10mL volumetric flask, add 0.1g of 1000U α-amylase, and perform enzymatic hydrolysis and demulsification at 50°C for 5min. After demulsification, the volume was adjusted to 10 mL with ethanol, centrifuged, and the supernatant was taken for HPLC detection. The measured VE content was 9.7%, and the calculated emulsification rate was 96.8%. (Refer to the literature J. Food Sci. 2015, 80, C680-C686 for the detection method).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com