Dark-patterned fully-polished surface ceramic product and preparation method thereof

A ceramic product, full polishing technology, applied in the field of building ceramic tiles, can solve the problems of many process control links, uneven dry application, uneven ink combination, etc., and achieve the effect of widening the color gamut and enriching the variety of colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

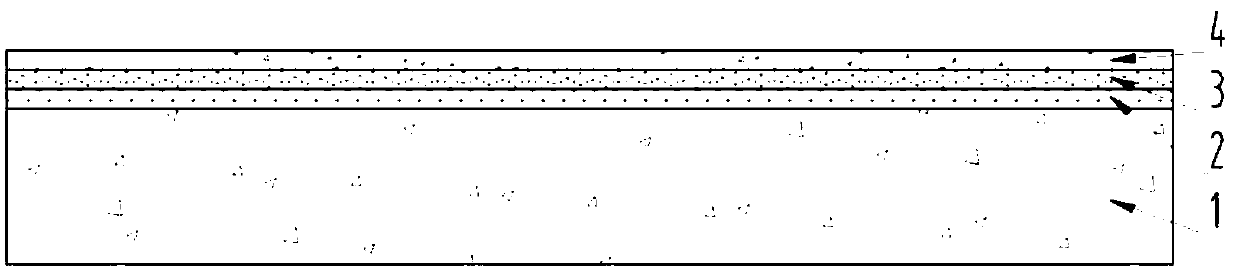

[0044] A kind of preparation method of the fully polished surface ceramic product of dark pattern, it comprises the following steps:

[0045] (1) Equipped with a conventional ceramic inkjet machine and equipped with zirconium white, blue, brown, yellow, black, orange, wrapped red, and transparent glaze inks in sequence, for standby;

[0046] Equipped with bottom glaze, spare;

[0047] Equipped with dry granule glaze, according to the above formula, 45% to 55% of solid dry granules, 4% to 8% of printing powder, 22% to 30% of glue, and 15% to 25% of water are mixed and prepared for use, and they are all percentages by weight;

[0048] Equipped with production line glaze line, glaze spraying facilities, spare;

[0049] (2), pressing the bottom blank of the ceramic tile and drying it;

[0050] (3), drench bottom glaze on the bottom blank surface after drying;

[0051] (4) According to the pre-input design patterns in the ceramic inkjet machine, spray-print on the surface of the...

Embodiment 1

[0059] (1), select kaolin, feldspar, quartz and other raw sand materials, and prepare green body porcelain powder according to conventional ceramic technology, and set aside;

[0060] (2), equipped with bottom glaze, spare;

[0061] According to the formula weight percentage, the composition is 59.2% of silicon dioxide, 7.8% of aluminum oxide, 6.7% of potassium oxide, 0.73% of sodium oxide, 11.2% of calcium oxide, 0.65% of magnesium oxide, 11% of zinc oxide, 1.2% of barium oxide, trioxide Diboron 1.1%, iron oxide 0.1%, titanium dioxide 0.04%, others are solid dry granules with ignition loss and trace impurities;

[0062] Then 50% of solid dry granules, 6% of printing powder, 26% of glue, and 18% of water are mixed and stirred to prepare dry granule glaze for subsequent use, all in percentages by weight;

[0063] Equipped with a conventional ceramic inkjet machine and equipped with black, blue, and packaged red in order, for standby;

[0064] Equipped with production line gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com