Three-color optical mixing LED point light source device

A point light source and light source group technology, which is applied in the field of three-color mixed light LED point light source devices, can solve problems such as insufficient color rendering, color distortion, and failure to emit light colors, so as to improve color rendering, increase color gamut, and increase light output. The effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

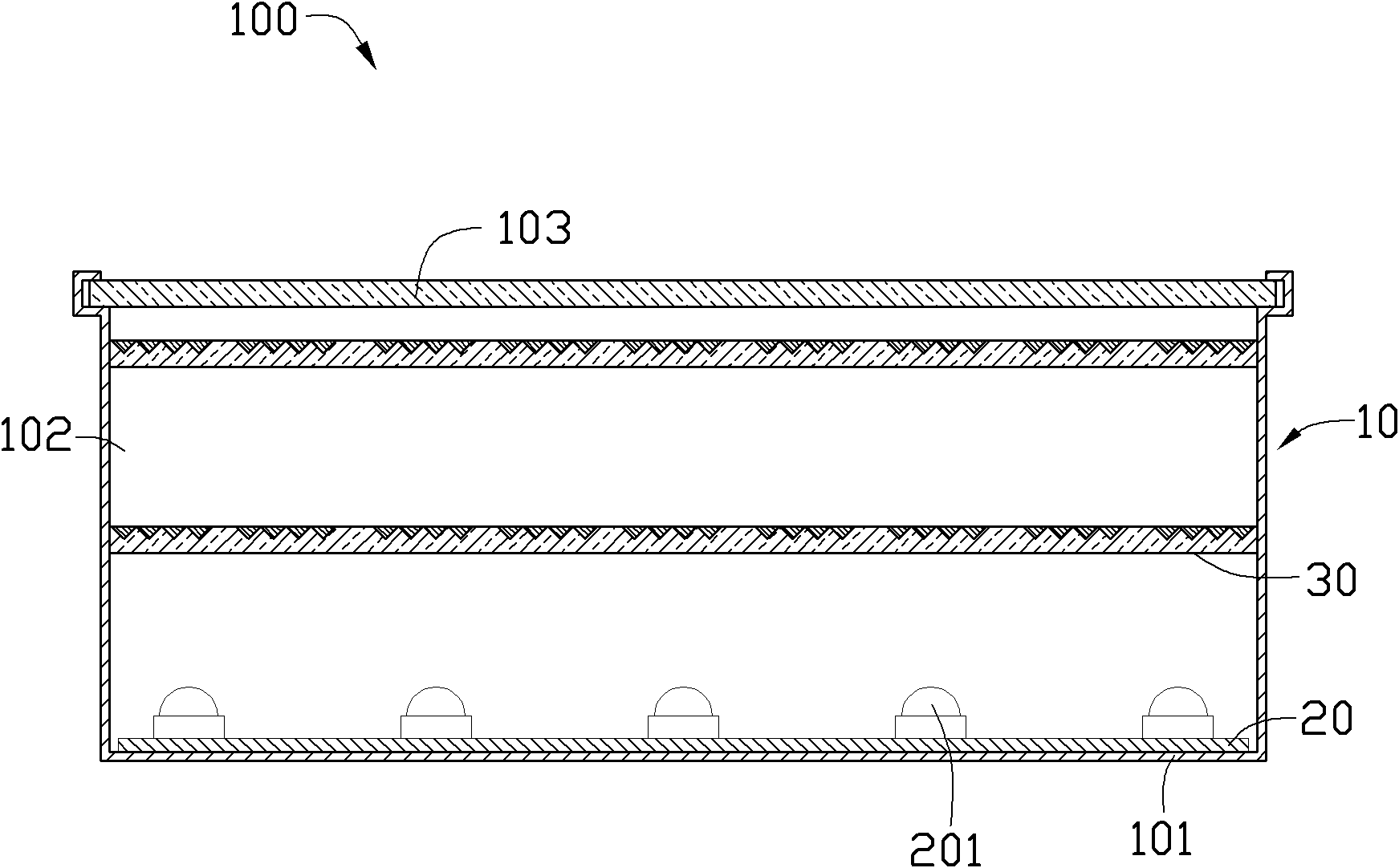

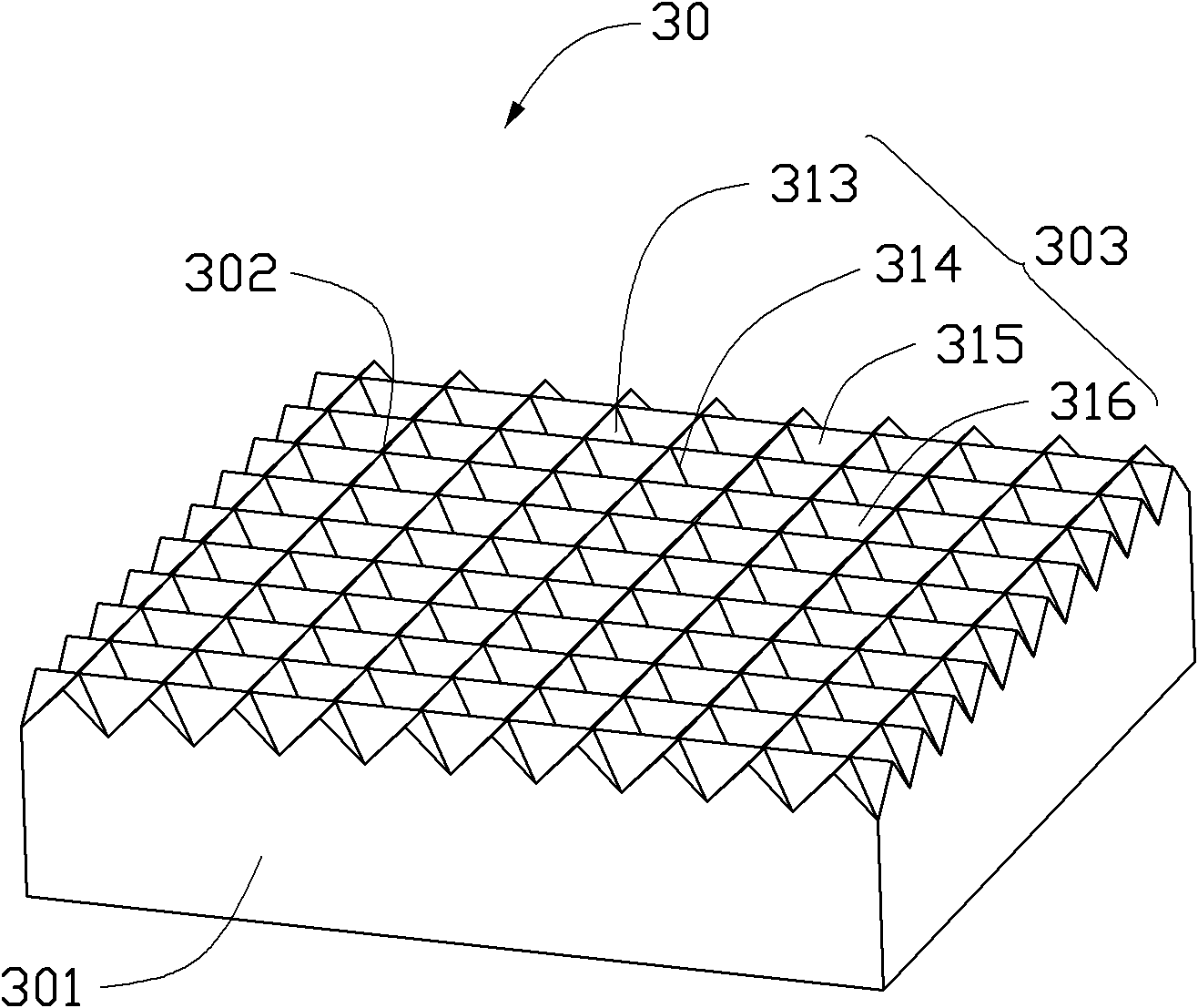

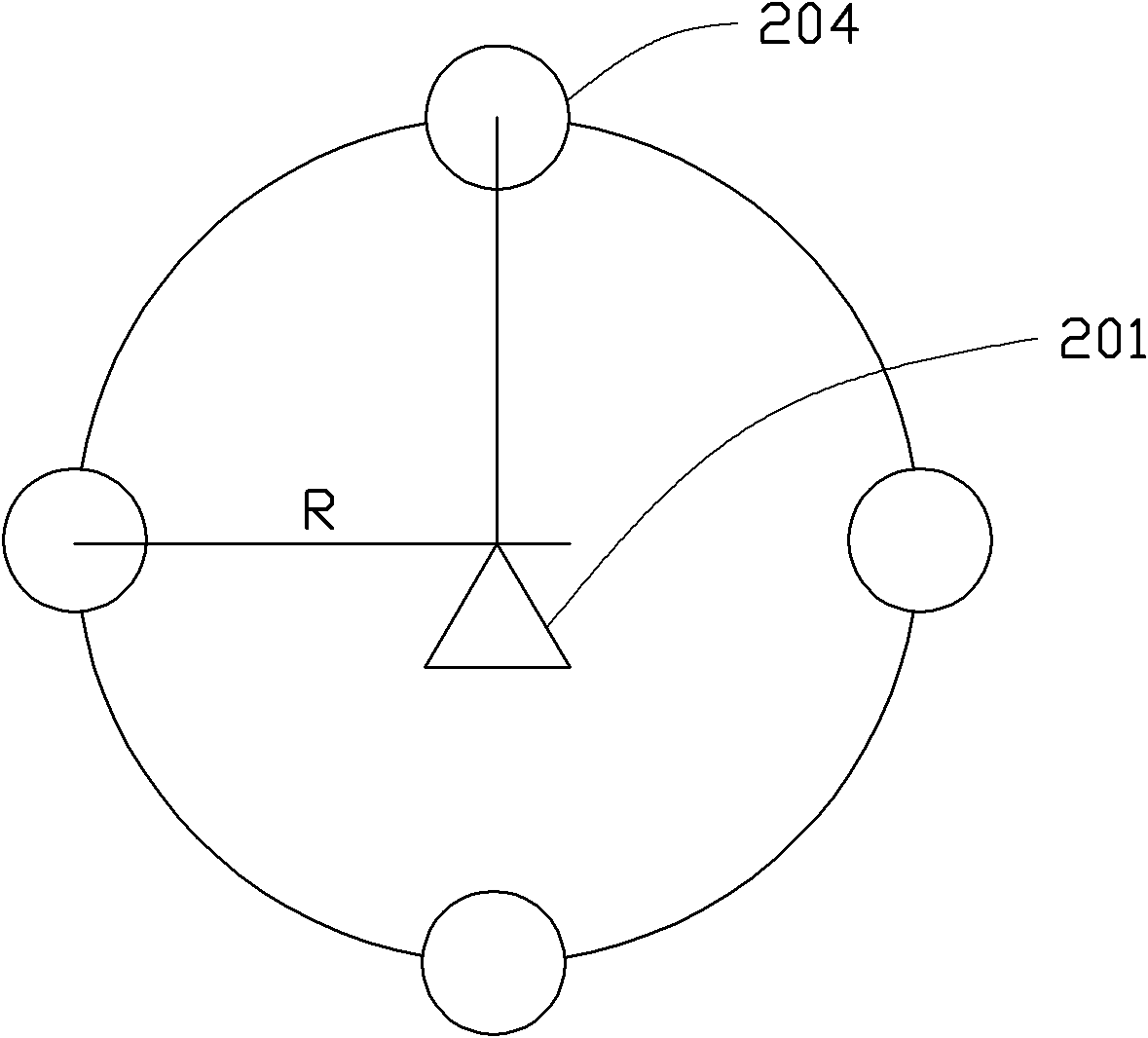

[0031] see figure 1 , a three-color light-mixing LED point light source device 100 includes a housing 10 , a circuit substrate 20 and a microprism optical plate 30 . The housing 10 includes a bottom plate 101 , sidewalls 102 extending around the bottom plate 101 , and a protective cover 103 . The bottom plate 101 and the side wall 102 define a receiving cavity. Described protective cover 103 is made by a kind of in the transparent material such as transparent glass, frosted glass, transparent plastic sheet, and protective cover 103 is positioned at the top of microprism optical plate 30, is used to protect the surface layer of microprism optical plate 30 from being polluted or scratched. In this embodiment, the housing 10 can be made of metal or plastic with high reflectivity, or metal or plastic coated with a high reflectivity coating, and the inner surface of the bottom plate 101 is coated with a high reflectivity coating. rate coating. The circuit substrate 20 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com