SAN/PMMA (Styrene-Acrylonitrile/Polymethyl Methacrylate) composite material for bathrooms and preparation method thereof

A composite material and raw material technology, applied in the field of bathroom materials, can solve the problems that the physical properties are not enough to meet the use of bathroom products, the acid and alkali resistance is not as good as that of ceramic materials, and the toughening SAN cannot be completely overcome, so as to improve the physical properties and acid resistance. Alkaline properties, improving processing fluidity, and the effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the following will be clearly and completely described in conjunction with the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, rather than Full examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

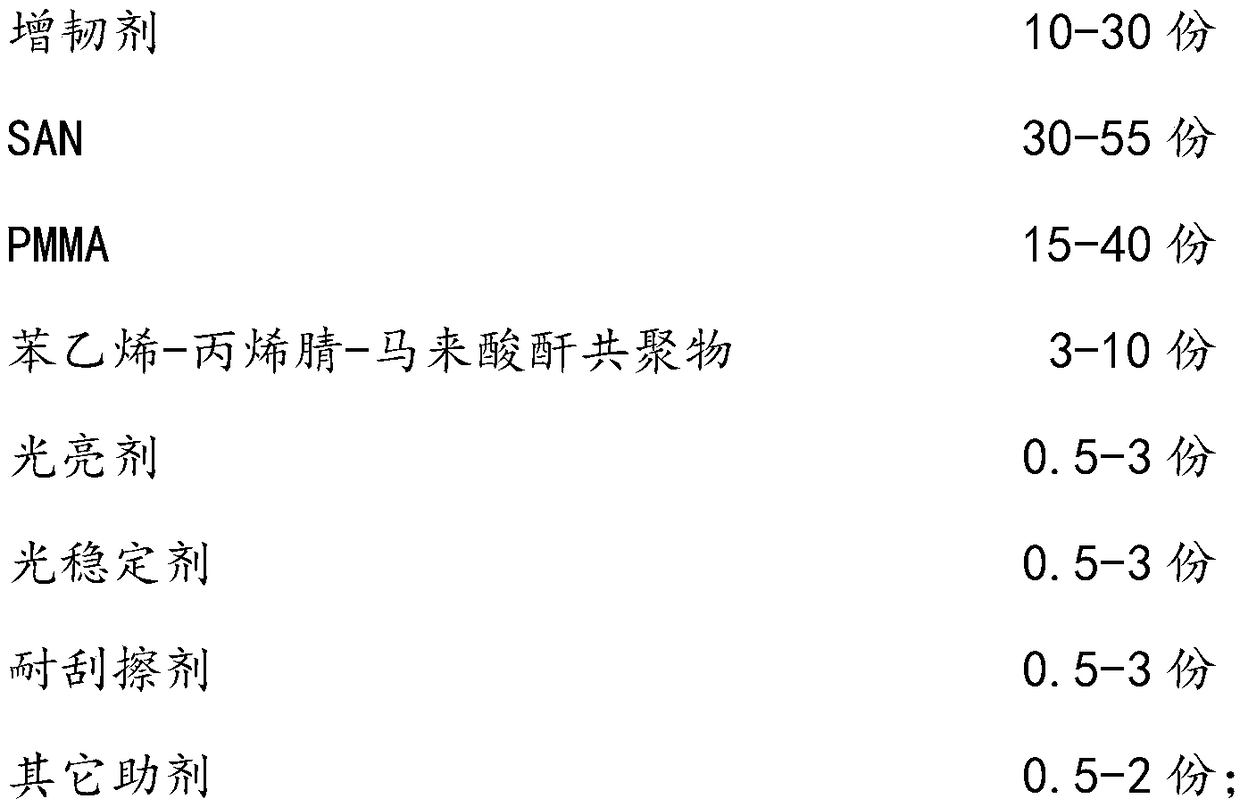

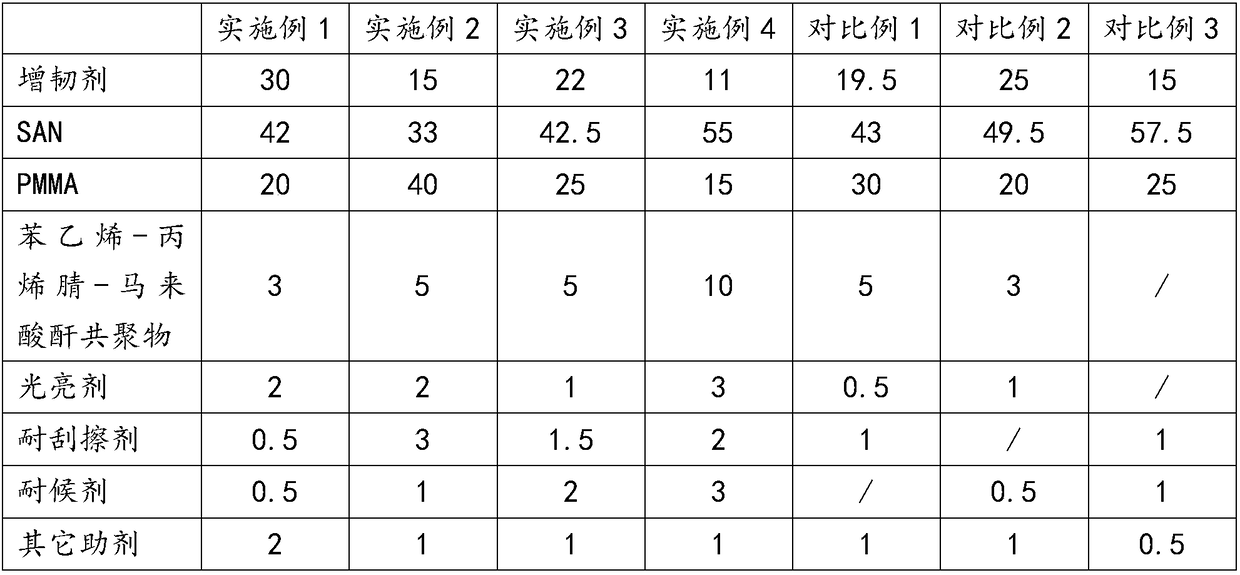

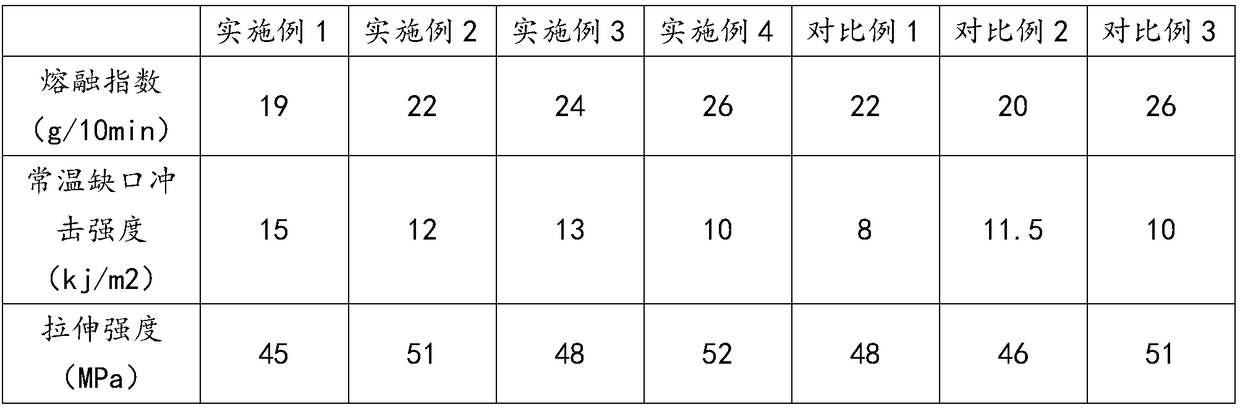

[0032] The present invention provides the formula (unit: weight part) of following embodiment and comparative example, as shown in table 1:

[0033] Table 1

[0034]

[0035] The present invention also provides the following embodiments of the preparation method, which comprises the following steps:

[0036] Step a, according to the ratio in the above table, weigh various raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com