A kind of modified magnesium sulfate cement and preparation method thereof

A magnesium sulfate and modification technology, which is applied in the field of modified magnesium sulfate cement and its preparation to achieve the effects of improving the degree of surface etching activation, improving the compressive strength and increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

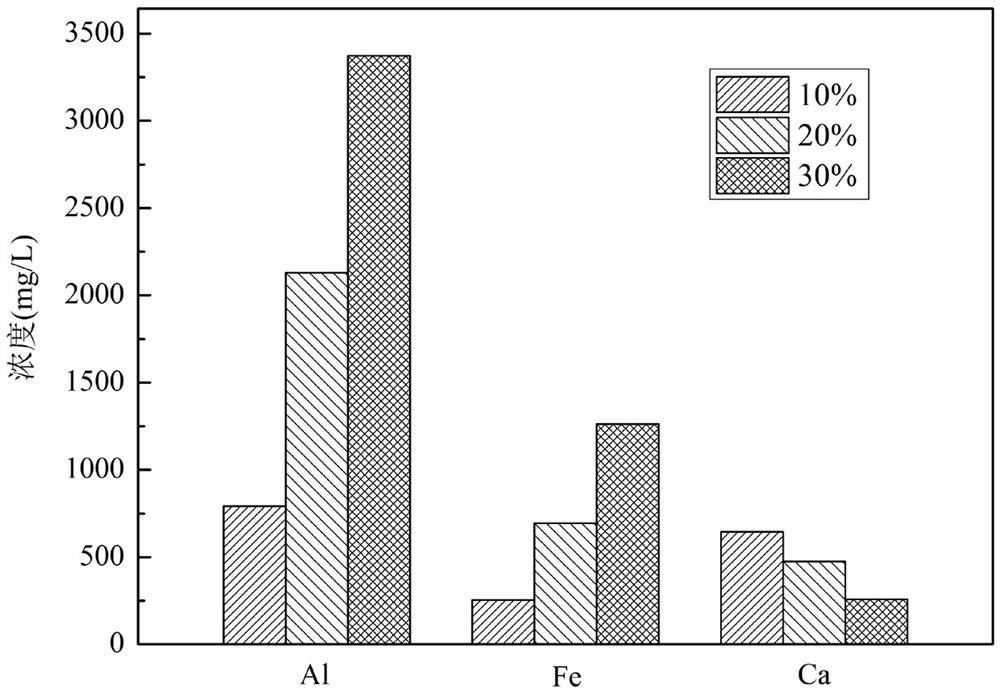

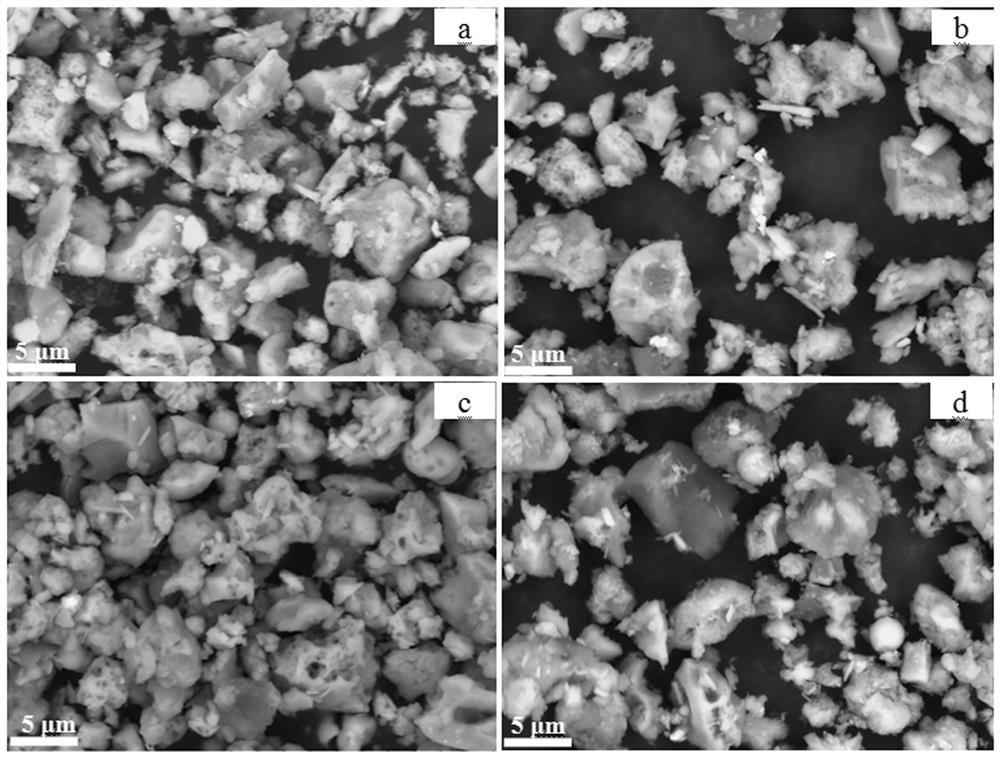

[0034] Three parts of 10 g ultrafine fly ash (1-5 μm) were weighed and added to 100 mL of 10%, 20% and 30% dilute sulfuric acid solution respectively, stirred at room temperature for 2 h, and then separated by filtration. Aluminum, iron and calcium in the filtrate were measured by ICP, the results are shown in figure 1 ; The obtained solid powder was washed with deionized water to neutrality, dried at 105 °C for 3~5 h, and then characterized by SEM and XRD. The results are shown in figure 2 , 3 ; The specific surface area was measured by low-temperature nitrogen adsorption, and the results were 19, 48 and 28 m 2 / g.

Embodiment 1

[0036](1) Weigh 58.80g of concentrated sulfuric acid, 24.96g of ultrafine fly ash, 126.05g of magnesium oxide and 217.26g of water are used for standby, (2) Add concentrated sulfuric acid to 204.63g of standby water to prepare a 20% dilute sulfuric acid solution, then add ultrafine fly ash, stir at room temperature for 2 hours, and obtain activated modified ultrafine powder Coal ash; (3) Slowly add 15% 18.91g of spare magnesia to the mixture obtained in step (2), adjust the stirring rate to 400 r / min, stir for 1.5 h, and continue stirring for 15 min after the addition is complete to make the active Magnesium oxide is fully dissolved to obtain a mixture of fly ash and magnesium sulfate solution; (4) According to the mass ratio of admixture to active magnesium oxide is 1:100, weigh 1.26g of citric acid and add it to the remaining water, stir and dissolve at room temperature and then add to step (3) In the obtained mixture, stir for 10 minutes to mix well, continue to add the rem...

Embodiment 2

[0038] (1) Weigh 58.80g of concentrated sulfuric acid, 56.19g of ultrafine fly ash, 151.26g of magnesia and 244.44g of water are used for standby, (2) Add concentrated sulfuric acid to 204.63g of standby water to prepare a 20% dilute sulfuric acid solution, then add ultrafine fly ash, stir at room temperature for 2 hours, and obtain activated modified ultrafine fly ash; 3) Slowly add 15% 22.69g of spare magnesia to the mixture obtained in step (2), adjust the stirring rate to 400 r / min, stir for 1.5 h, and continue stirring for 15 min after the addition is complete to make the active Magnesium oxide is fully dissolved to obtain a mixture of fly ash and magnesium sulfate solution; (4) According to the mass ratio of admixture to active magnesium oxide is 1:100, weigh 1.51g of citric acid and add it to the remaining water, stir and dissolve at room temperature, and then add to step (3) In the obtained mixture, stir for 10 minutes to mix well, continue to add the remaining magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com