Long and thin die-cutting product molding equipment and molding technology

A molding equipment and slender technology, applied in the field of slender die-cutting product molding equipment and molding technology, can solve the problems of increasing equipment cost burden, inability to process, difficult to operate, etc., to avoid huge impact force and improve production efficiency , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

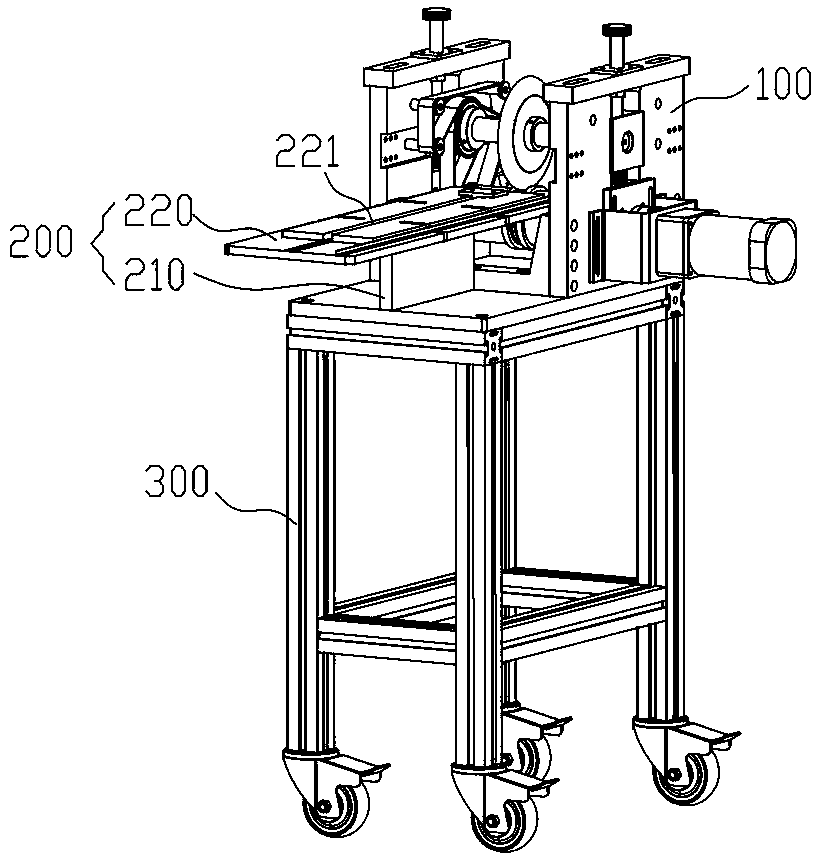

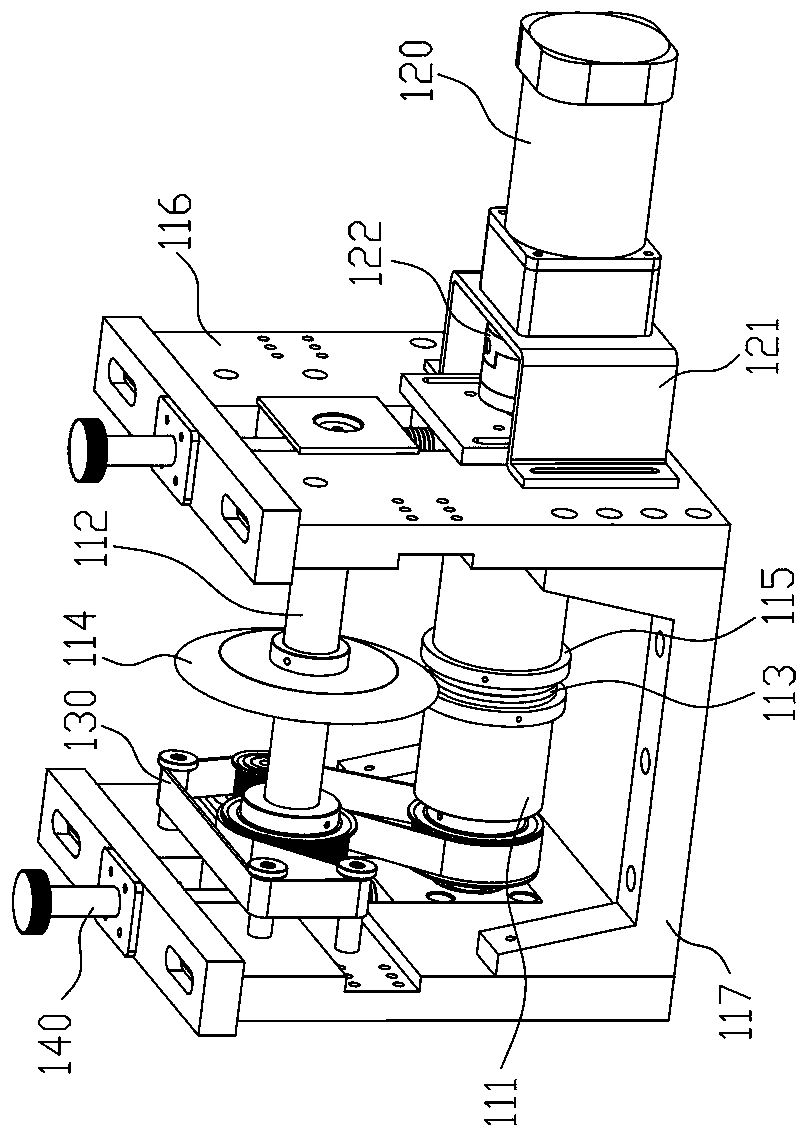

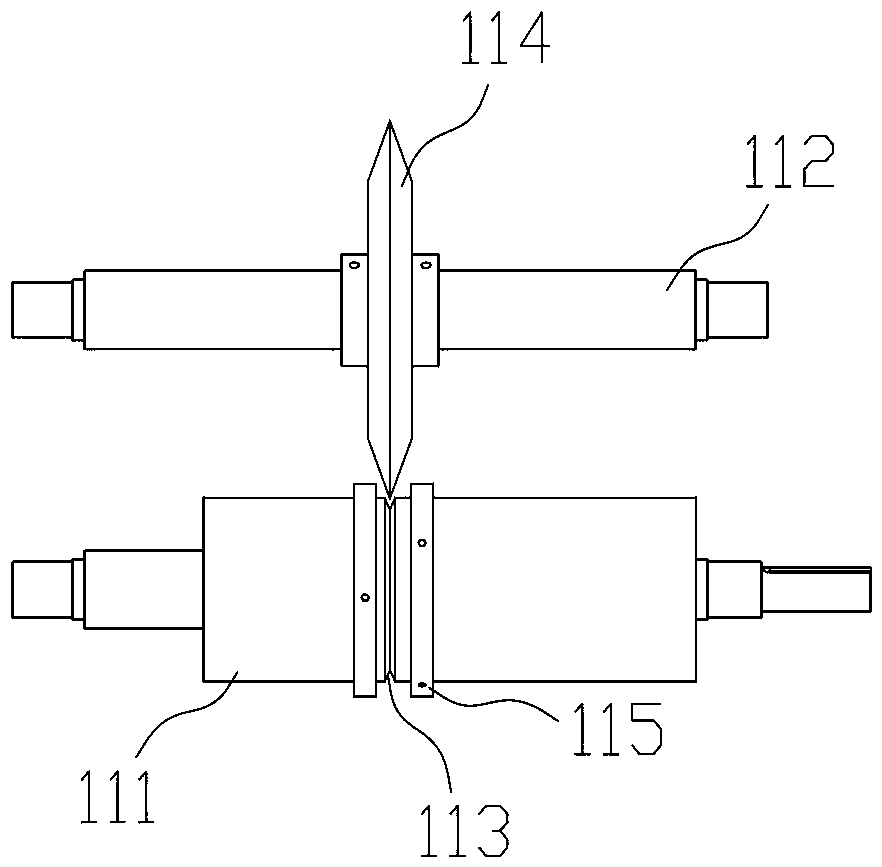

[0038] The elongated die-cutting product forming equipment in the embodiment of the present invention is as attached Figure 1-5 As shown, the forming mechanism 100 is included, and the forming mechanism includes a forming shaft 111, a hob forming groove 113 located on the forming shaft, a driven shaft 112 and a hob forming block 114 located on the driven shaft; the hob forming block is It is wheel-shaped, and the edge is matched with the hob forming groove, and the slender die-cut raw material is pressed into shape by the force between the hob forming block and the hob forming groove.

[0039] The hob forming groove is set on the forming shaft and rotates under the drive of the forming shaft; the hob forming block is set on the driven shaft and rotates in reverse under the drive of the driven shaft; the hob forming groove and the hob forming block T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com