A mercury-free high-power zinc-manganese battery and battery powder, zinc cylinder and mercury-free paste layer paper

A zinc-manganese battery, high-power technology, applied in battery electrodes, dry batteries, aqueous electrolyte batteries, etc., can solve the problems of reducing gas evolution, oil leakage, and battery self-discharge, etc. Improve the effect of hydrogen absorption overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

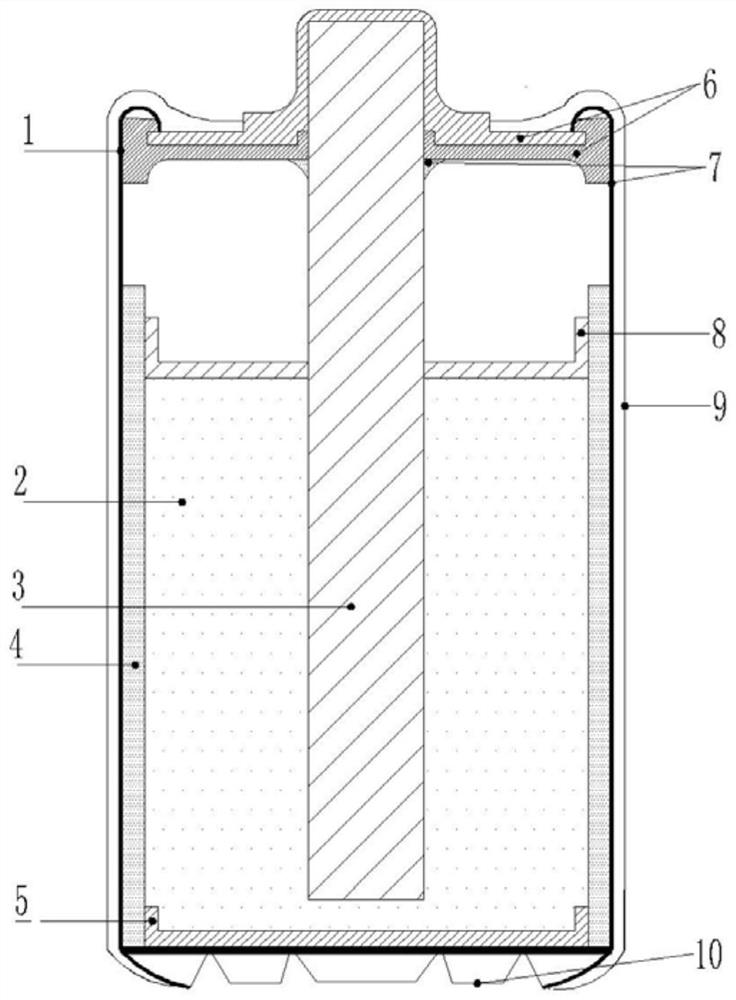

Image

Examples

Embodiment 1

[0022] This embodiment provides a mercury-free high-power zinc-manganese battery cell powder. The raw material components include: 220 kg of electrolytic manganese dioxide, 40 kg of acetylene black, 2.5 kg of zinc oxide, and 200 kg of electrolyte. The pH value of the battery powder was adjusted to 4.8, and the water content was 29.5%. In the electrolytic manganese dioxide, manganese dioxide ≥ 91.5%, iron ≤ 0.002%, copper ≤ 0.0005%, nickel ≤ 0.0001%, water ≤ 2%; the electrolyte is zinc chloride and ammonium chloride in molar ratio 0.197:0.075 mixed aqueous solution.

[0023] Further, a zinc cylinder of a mercury-free high-power zinc-manganese battery is provided, the material composition of the zinc cylinder includes 0.002% of bismuth, 0.001% of indium and 0.003% of aluminum, and the rest is zinc. The zinc cylinder is prepared by the following method: after mixing zinc, bismuth, indium and aluminum, heating to 430°C to obtain a melt, fully stirring, pouring to obtain a zinc pl...

Embodiment 2

[0039] This embodiment provides a mercury-free high-power zinc-manganese battery cell powder. The raw material components include: 210 kg of electrolytic manganese dioxide, 35 kg of acetylene black, 2 kg of zinc oxide, and 180 kg of electrolyte. Adjust the pH value of the battery powder to 5.3, and the moisture content to 30.5%. In the electrolytic manganese dioxide, manganese dioxide ≥ 91.5%, iron ≤ 0.002%, copper ≤ 0.0005%, nickel ≤ 0.0001%, water ≤ 2%; the electrolyte is zinc chloride and ammonium chloride by mole A mixed aqueous solution with a ratio of 0.1:0.06.

[0040] Further, a zinc cylinder for a mercury-free high-power zinc-manganese battery is provided, the material composition of the zinc cylinder includes 0.001% bismuth, 0.0005% indium and 0.002% aluminum, and the rest is zinc. The zinc cylinder is prepared by the following method: mixing zinc, bismuth, indium and aluminum, heating to 440°C to obtain a melt, fully stirring, pouring to obtain a zinc plate, punchi...

Embodiment 3

[0056] This embodiment provides a mercury-free high-power zinc-manganese battery cell powder. The raw material components include: 230 kg of electrolytic manganese dioxide, 45 kg of acetylene black, 3 kg of zinc oxide, and 220 kg of electrolyte. The pH value of the battery powder was adjusted to 5.0, and the water content was 29.8%. In the electrolytic manganese dioxide, manganese dioxide ≥ 91.5%, iron ≤ 0.002%, copper ≤ 0.0005%, nickel ≤ 0.0001%, water ≤ 2%; the electrolyte is zinc chloride and ammonium chloride by mole A mixed aqueous solution with a ratio of 0.2:0.08.

[0057] Further, a zinc cylinder for a mercury-free high-power zinc-manganese battery is provided, the material composition of the zinc cylinder includes 0.003% bismuth, 0.0015% indium and 0.004% aluminum, and the rest is zinc. The zinc cylinder is prepared by the following method: after mixing zinc, bismuth, indium and aluminum, heating to 440°C to obtain a melt, fully stirring, pouring to obtain a zinc pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com