Polarization-used fixture, piezoelectric layer polarization method and ultrasonic biometric device manufacturing method

A piezoelectric layer and fixture technology, applied in the field of ultrasonic identification, can solve the problems of incapable of piezoelectric layer polarization, affecting piezoelectric performance of piezoelectric layer, increasing the difficulty of piezoelectric layer polarization, etc., achieving simple operation, preventing The effect of high voltage electrical breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

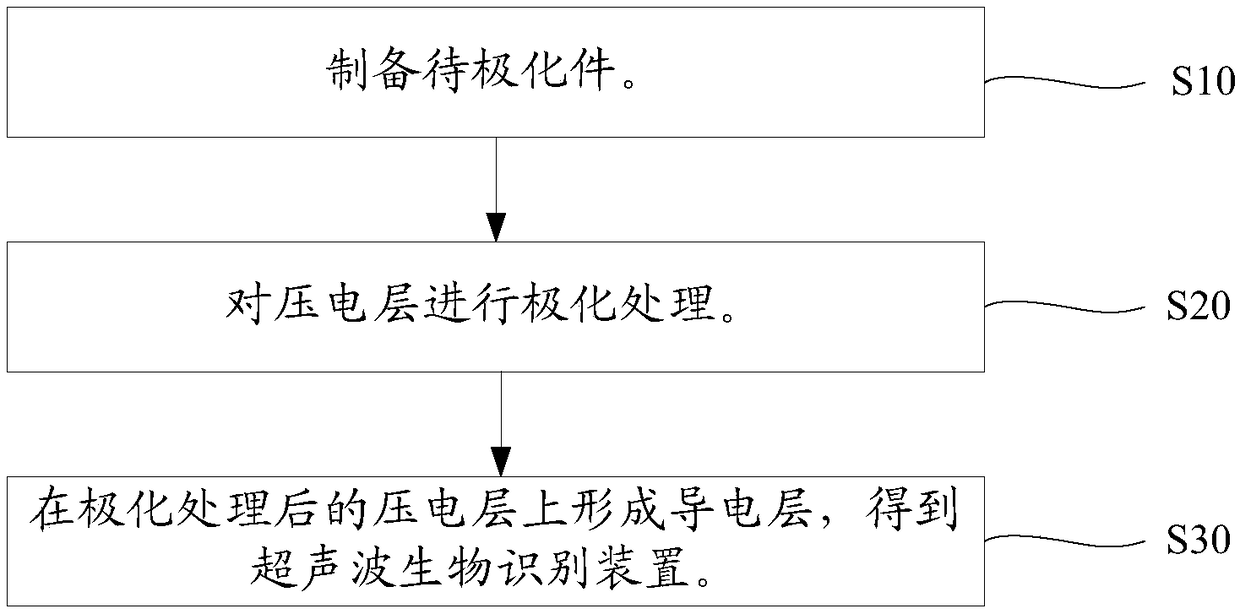

[0046] like figure 1 As shown, the preparation method of an ultrasonic biometric identification device in one embodiment includes the following steps:

[0047] Step S10: Prepare the member to be polarized.

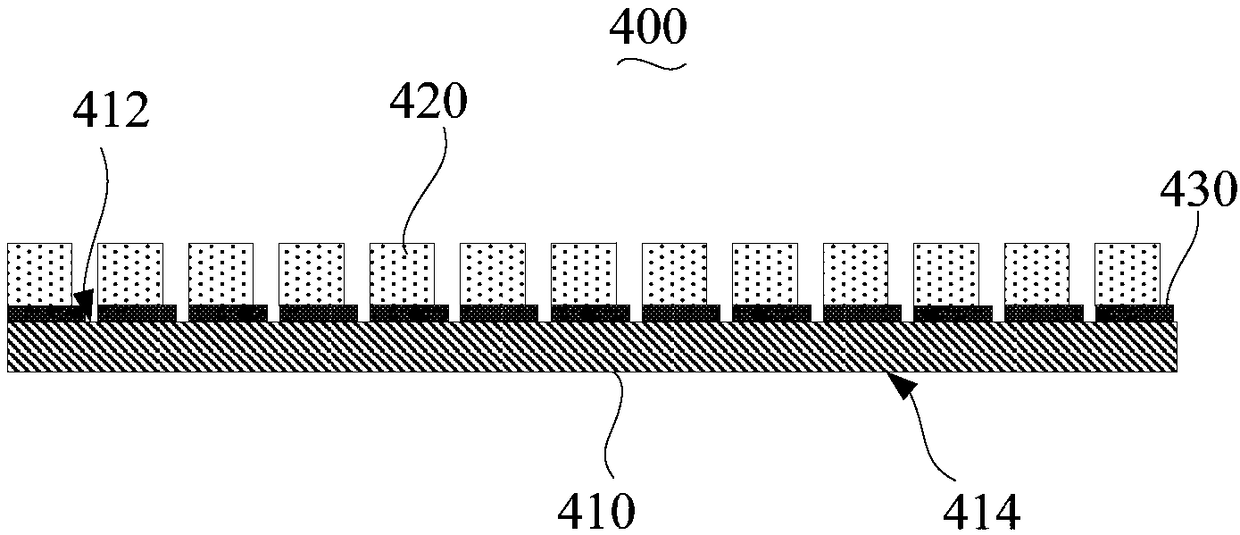

[0048] Please also refer to figure 2 , the member 400 to be polarized includes a substrate 410 and a piezoelectric layer 420, the substrate 410 has an opposite first surface 412 and a second surface 414, the first surface 412 is provided with a circuit layer 430, and the piezoelectric layer 420 is stacked on the first surface 412 and cover part of the circuit layer 430 . In the illustrated embodiment, multiple columns of piezoelectric layers 420 are formed on the first surface 412 of the substrate 410 , and the multiple columns of piezoelectric layers 420 are parallel. Wherein, each column of piezoelectric layers 420 has a plurality of piezoelectric layers 420 at intervals.

[0049] Specifically, the substrate 410 is a thin film transistor. The material of the piezoe...

Embodiment 1

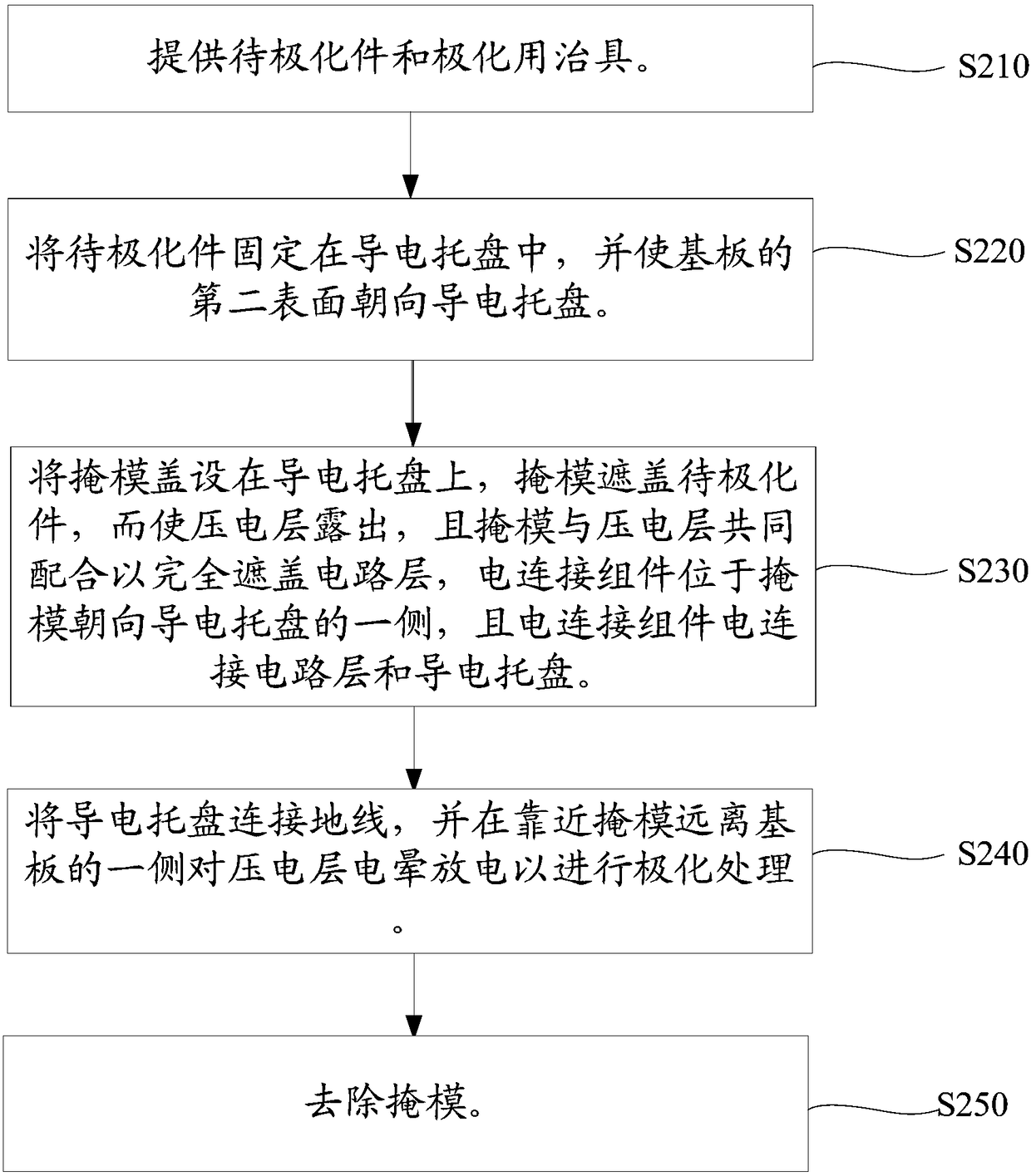

[0096] The piezoelectric layer polarization method of the above step S20 is used to simultaneously polarize the piezoelectric layers 420 of the plurality of components to be polarized 400, wherein the material of the piezoelectric layer 420 is a copolymer of polyvinylidene fluoride and trifluoroethylene The molar ratio of polyvinylidene fluoride and trifluoroethylene is 60:40, the working area of the plate-shaped body 532 of the mask 530 and the thickness of each masking part 534 are 0.7 mm, and the polarization equipment used for polarization is The corona polarization equipment of American Areesys Technology Company, the voltage of the metal grid is -2kV; the voltage of the corona roller is -6.5kV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com