Coordinated control system of thermal power generating unit and coordinated control method of coordinated control system

A technology for coordinating control systems and thermal power units, applied in general control systems, control/regulation systems, electrical program control, etc., can solve problems affecting the safe and stable operation of unit units, overpressure or long-term low pressure, and other parameters exceeding limits , to achieve the effect of ensuring stability, improving stability, and satisfying load response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

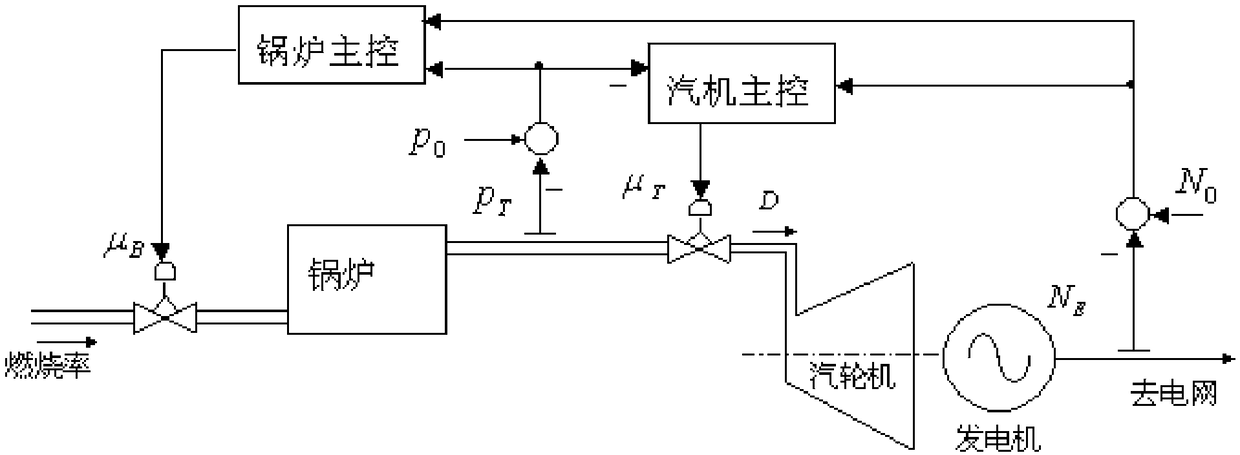

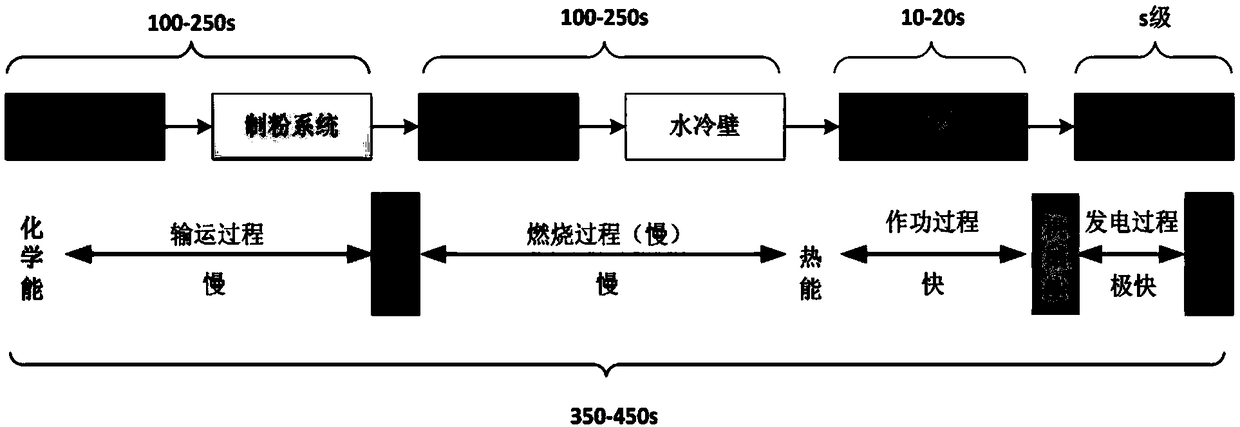

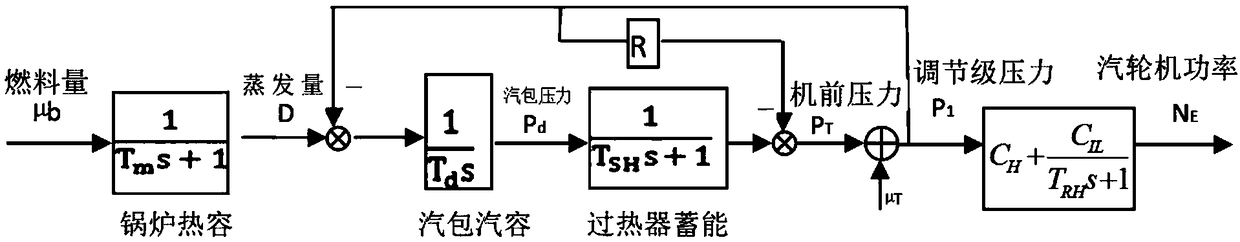

[0048] see figure 1 as well as figure 2 , the inventor of this case has conducted detailed and in-depth research. In the prior art, the coordinated control objects of thermal power unit units are mainly steam turbines and boilers. While the unit responds quickly to the load, the deviation of the main steam pressure must be controlled within the normal range. However, the thermal power unit is composed of multiple systems, and the energy conversion links generally include coal yards, pulverizing systems, furnaces, water walls, steam turbines, and generators. and other components, the chemical energy in the coal in the coal yard is transported through the pulverizing system to the boiler for combustion to generate heat, and the heat is transferred to the water wall, and the water in the water wall turns into steam to generate thermal potential energy, and then the steam Work is done by the steam turbine, which converts the thermal potential energy into mechanical energy, and t...

Embodiment 2

[0115] This embodiment provides a coordinated control method for thermal power units on the basis of Embodiment 1. The coordinated control method for thermal power units includes:

[0116] Take the load command N of the thermal power unit 0 As a feed-forward signal, it drives the main controller of the boiler to act in advance, and opens or closes the high-profile door of the steam turbine in response to the load command N 0 ; make the feedforward signal act on the main controller of the boiler, increase or decrease the fuel volume and air volume, and perform step control on the boiler;

[0117] Compensating the dynamic delay of the boiler according to the steam pressure deviation ratio, so as to adjust the fuel quantity of the boiler;

[0118] Correcting the main controller of the boiler according to the deviation of the main steam pressure to adjust the combustion rate of the boiler.

Embodiment 3

[0120] In this embodiment, in the coordinated control system of thermal power units, the coordination mode of the feedback signal is the boiler following control mode, and the coordination mode of the feedforward signal is the power command indirect energy balance as the main mode, and the direct energy balance of the boiler as the auxiliary combined control method.

[0121] see Figure 7 , in the boiler following control mode, the steam turbine controls the load power of the unit, and the boiler controls the main steam pressure. When unit load command N 0 When increasing (i.e. N 0 -N E >0), so that the main controller of the steam turbine Wa1(s) issues an instruction to increase the opening of the steam turbine regulating valve, thereby increasing the flow of main steam entering the steam turbine, and finally making the actual load of the unit N E with load instruction N 0 same. The change of the main steam flow rate causes the main steam pressure P T Change, at this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com