Chemical copper plating activating agent, preparation method thereof as well as activating agent based method of preparing circuit by adopting fully additive method

An electroless copper plating and activator technology, which is applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of complex and time-consuming preparation, the influence of conductive ink, and poor universality of the bridging layer on the substrate surface. To achieve the effect of ensuring uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

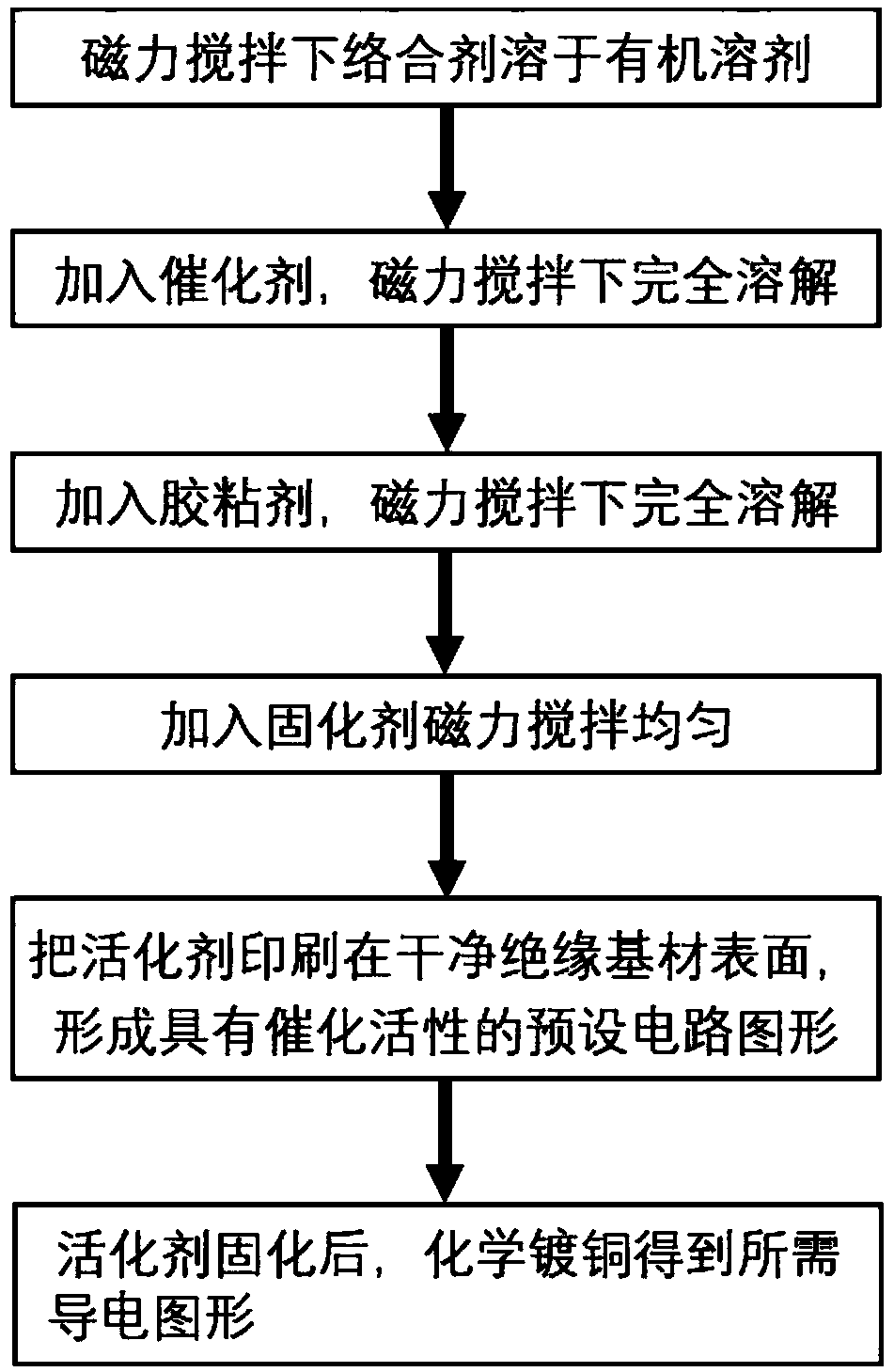

[0066] Select thiourea as a complexing agent, dissolve it in propylene glycol methyl ether under the condition of room temperature and magnetic stirring 200r / min, and obtain a solution with a thiourea concentration of 0.03mol / L; add catalyst AgNO 3 , completely dissolved under magnetic stirring to obtain a solution with a silver ion concentration of 0.01mol / L; then add 1.5mol / L bisphenol A epoxy resin and completely dissolve under magnetic stirring; then add an appropriate amount of curing agent 593 and magnetically stir evenly, Until the viscosity is 50-80mPa·S, the surface tension is between 25-45mN / m; use inkjet printing equipment to print the activator on the surface of the epoxy glass fiber substrate to form a preset circuit diagram with catalytic activity; room temperature curing Cooperate with electroless copper plating to obtain the required conductive pattern.

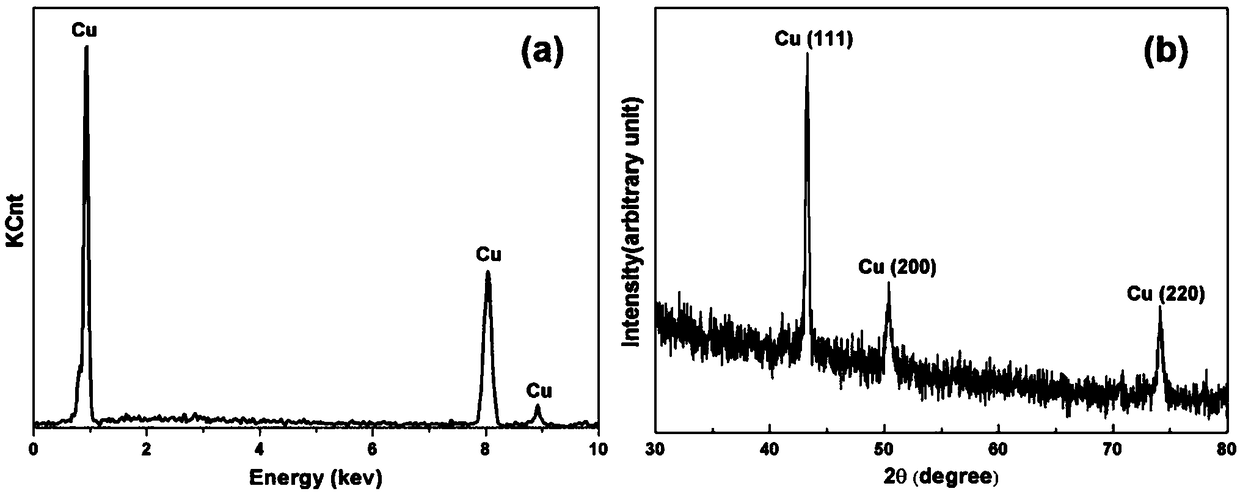

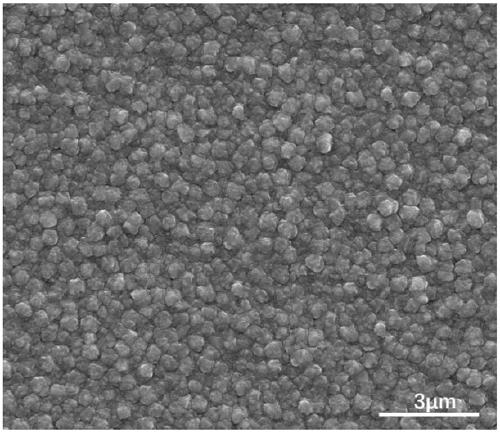

[0067] figure 2 a is the EDS energy spectrum analysis diagram of the copper layer after electroless coppe...

Embodiment 2

[0070] The operation of this embodiment is basically the same as that of Example 1, except that the composition of the electroless copper plating activator is specifically: the organic solvent is propylene glycol methyl ether acetate, and the concentration of 3-mercaptopropyltriethoxysilane is 0.1mol / L, AgNO 3 The concentration of the novolak epoxy resin is 0.015mol / L, the concentration of the novolak epoxy resin is 2mol / L, add an appropriate amount of curing agent 593 and magnetically stir evenly until the viscosity is 50-80mPa·S and the surface tension is between 25-45mN / m.

[0071] Cyclopenta-2,4-dienyl-1-thione (C 5 h 4 S) and 1-pyrrole-1-thiol (C 4 h 5 NS)

Embodiment 3

[0073] The operation of this embodiment is basically the same as that of Example 1, except that the composition of the electroless copper plating activator is specifically: the organic solvent is dipropylene glycol methyl ether, and the concentration of 3-aminopropyltriethoxysilane is 0.5mol / L, AgNO 3 The concentration of the epoxy resin is 0.02mol / L, and the concentration of the glycerol ether epoxy resin is 3mol / L. Add an appropriate amount of curing agent 593 and magnetically stir evenly until the viscosity is 50-80mPa·S and the surface tension is between 25-45mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com