A kind of bimetallic cast-welded composite roll and its preparation method

A composite roll and bimetallic technology, applied in the field of rolls, can solve the problems of cracks on the roll body that are not easy to control, the joint area of the composite interface is uneven, and it is difficult to ensure the integrity of the joint area, etc., to achieve low C content, large rolling The effect of suppressing cyclic stress and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

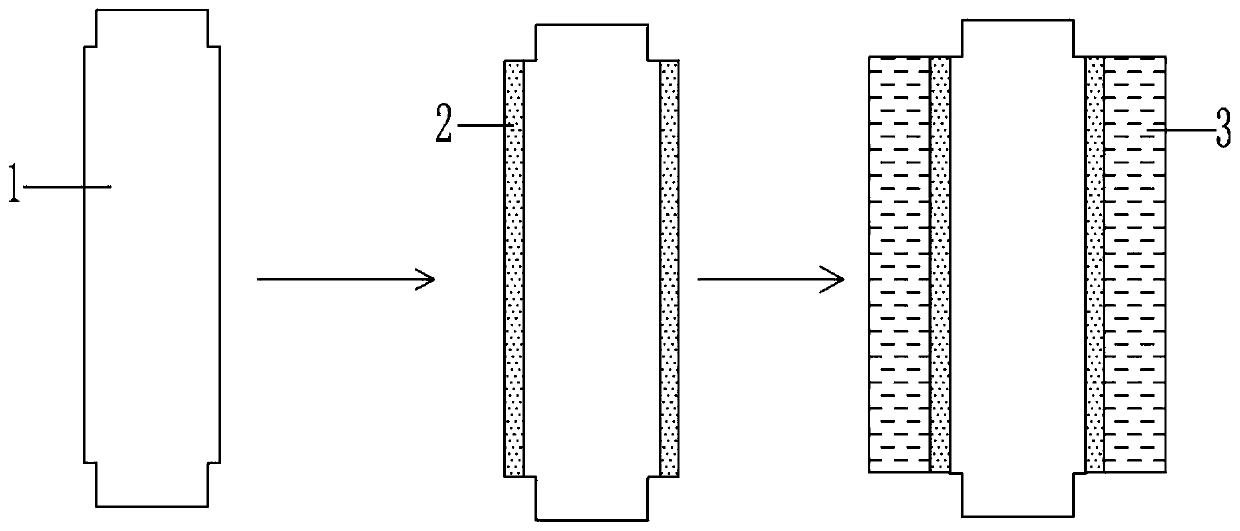

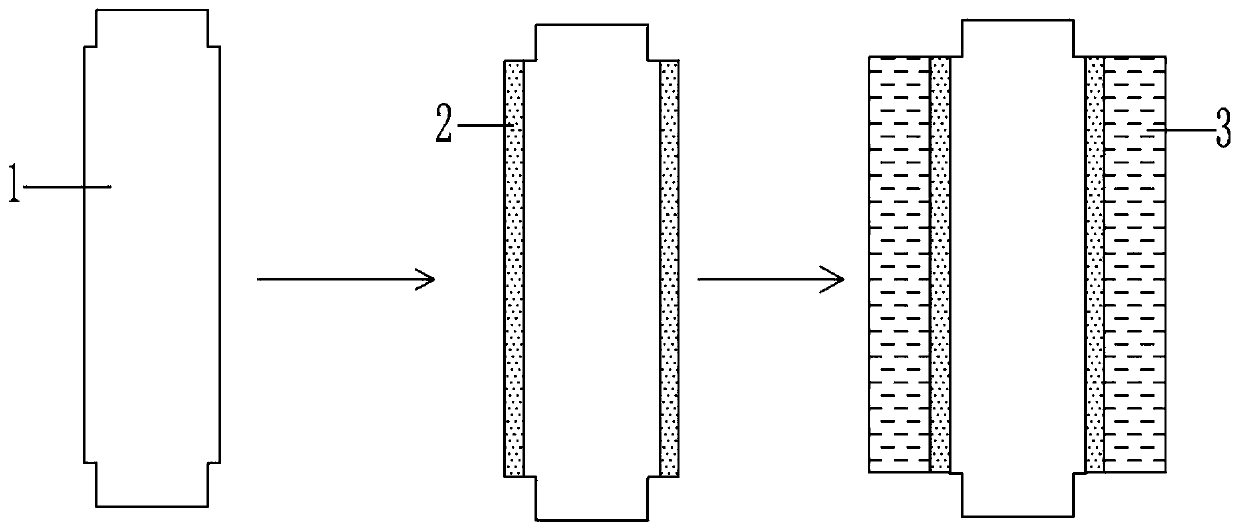

[0030] The preparation method of the bimetal cast-welded composite roll of the present embodiment comprises the following steps:

[0031] Step 1. Preparation of alloy steel roll core: cast alloy steel roll core by sand casting method; the alloy steel roll core includes the following components in mass percentage: C 0.26%, Si 1.5%, Mn 1.97%, Cr 1.62%, Mo 0.459%, the balance is Fe; the melting point of the alloy steel roll core is 1420°C;

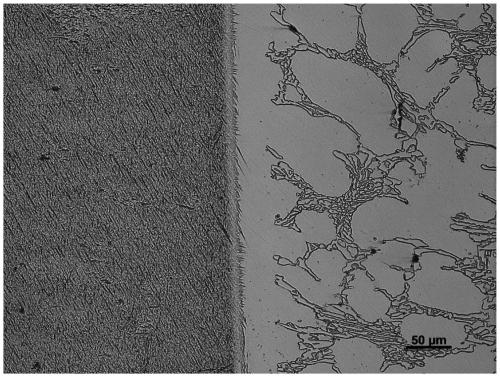

[0032] Step 2, preparing the surfacing layer: the alloy steel roller core cast in step 1 is subjected to shot blasting, and the surface of the alloy steel roller core after shot blasting is surfacing welding high chromium cast iron welding wire to obtain an alloy with a surfacing layer on the surface Steel roller core; the surfacing layer includes the following components in mass percentage: C 2.0%, Cr 15.0%, and the balance is Fe; the melting point of the surfacing layer is 1200°C, and the thickness of the surfacing layer is 6.5mm ;

[003...

Embodiment 2

[0050] The preparation method of the bimetal cast-welded composite roll of the present embodiment comprises the following steps:

[0051] Step 1. Preparation of alloy steel roll core: casting alloy steel roll core by sand casting method; the alloy steel roll core includes the following components in mass percentage: C 0.22%, Si 1.5%, Mn 1.97%, Cr 1.62%, Mo 0.459%, the balance is Fe; the melting point of the alloy steel roll core is 1420°C;

[0052] Step 2, preparing the surfacing layer: the alloy steel roller core cast in step 1 is subjected to shot blasting, and the surface of the alloy steel roller core after shot blasting is surfacing welding high chromium cast iron welding wire to obtain an alloy with a surfacing layer on the surface Steel roller core; the surfacing layer includes the following components in mass percentage: C 2.8%, Cr 20.0%, and the balance is Fe; the melting point of the surfacing layer is 1200°C, and the thickness of the surfacing layer is 3mm;

[0053...

Embodiment 3

[0058] The preparation method of the bimetal cast-welded composite roll of the present embodiment comprises the following steps:

[0059] Step 1. Preparation of alloy steel roll core: casting alloy steel roll core by sand casting method; the alloy steel roll core includes the following components in mass percentage: C 0.22%, Si 1.5%, Mn 1.97%, Cr 1.62%, Mo 0.459%, the balance is Fe; the melting point of the alloy steel roll core is 1420°C;

[0060] Step 2, preparing the surfacing layer: the alloy steel roller core cast in step 1 is subjected to shot blasting, and the surface of the alloy steel roller core after shot blasting is surfacing welding high chromium cast iron welding wire to obtain an alloy with a surfacing layer on the surface Steel roller core; the surfacing layer includes the following components in mass percentage: C 3.6%, Cr 26.0%, and the balance is Fe; the melting point of the surfacing layer is 1220°C, and the thickness of the surfacing layer is 10mm;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com