Combined collecting agent for niobium-titanium-uranium ore floatation and niobium-titanium-uranium ore floatation method

A technology combining collector and niobium-titanium ore, which is applied in flotation, solid separation, etc., can solve the problems of large amount of collector benzylhydroxamic acid, low recovery rate of niobium-titanium-uranium ore, and high flotation cost , to achieve the effect of reducing ore processing capacity and reagent consumption, low flotation temperature requirements, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The main uranium-containing minerals in a gravity separation concentrate are niobium-titanium-uranium ore, and the gangue minerals mainly include microplagioclase, calcite, quartz, neonite, albite, biotite, etc., and the grade of uranium is 0.073%.

[0043] (1) The combined collector is prepared according to the ratio that the mass fraction of carbenic acid accounts for 80%, and the mass fraction of butyl xanthate accounts for 20%.

[0044] (2) The combined collector is prepared into an aqueous solution with a mass fraction of 1% with hot water at a temperature of 50°C.

[0045] (3) Grind the fineness of the gravity-selected concentrate to -0.074mm, accounting for 60%, adjust the concentration of the pulp to 25%, and put it into the flotation cell, and adjust the Ph value of the pulp to 5 with concentrated sulfuric acid.

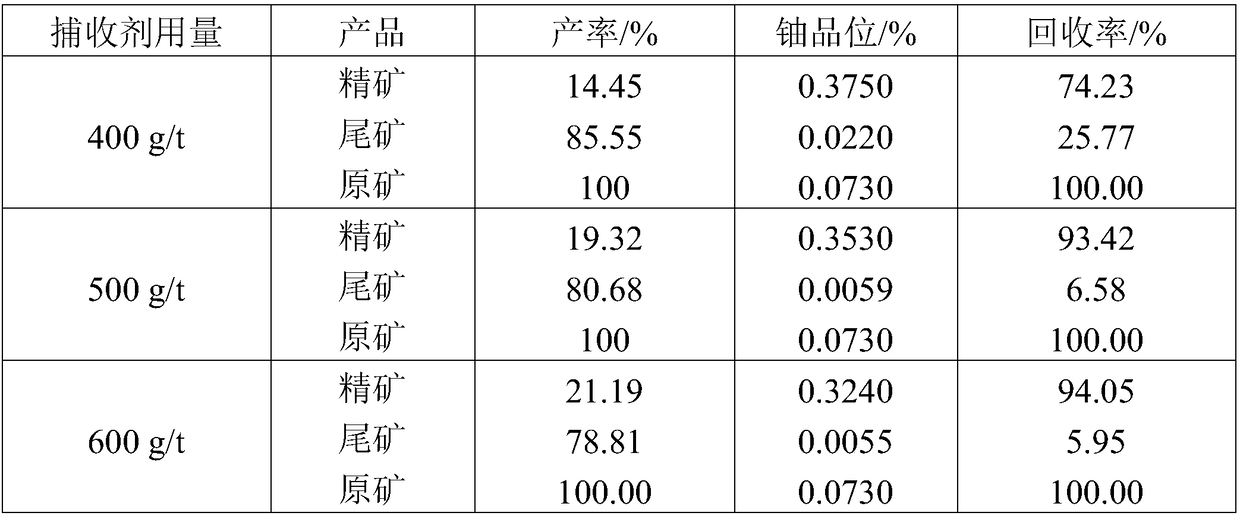

[0046] (4) Use a roughing process to investigate the flotation effect of niobium-titanium-uranium ore, change the amount of combined collectors, resp...

Embodiment 2

[0050] The main uranium-containing minerals in a gravity separation concentrate are niobium-titanium-uranium ore, and the gangue minerals mainly include microplagioclase, calcite, quartz, neonite, albite, biotite, etc., and the grade of uranium is 0.073%.

[0051] (1) The combined collector is prepared according to the ratio that the mass fraction of carbenic acid accounts for 75%, and the mass fraction of butyl xanthate accounts for 25%.

[0052] (2) The combined collector is prepared into an aqueous solution with a mass fraction of 2% with hot water at a temperature of 50°C.

[0053] (3) Grind the fineness of the gravity-selected concentrate to -0.074mm, accounting for 65%, adjust the concentration of the pulp to 30%, and put it into the flotation cell, and adjust the Ph value of the pulp to 5.5 with concentrated sulfuric acid.

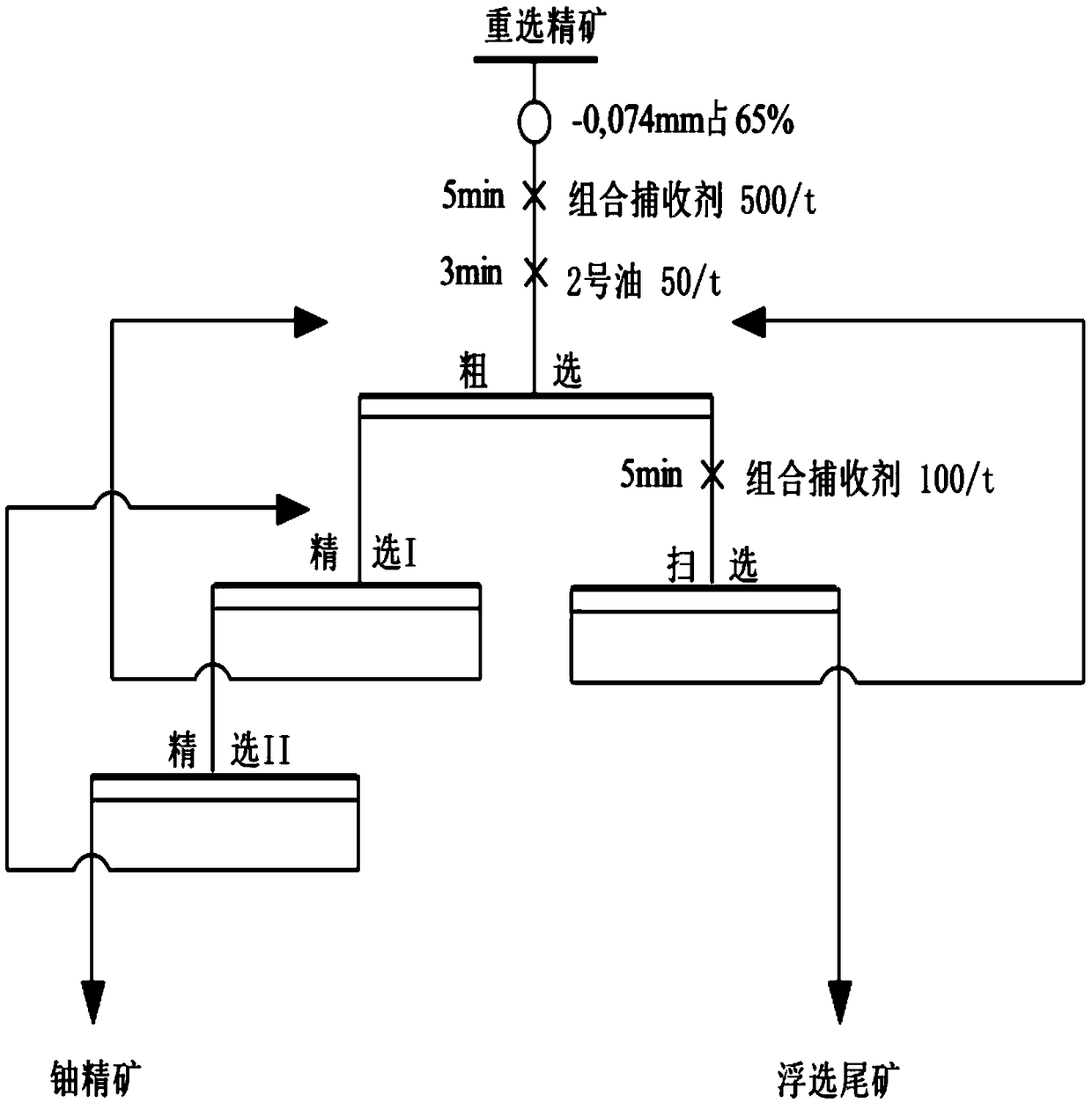

[0054] (4) Adopt one-time roughing and twice-selection open-circuit process for flotation of niobium-titanium-uranium ore. During roughing, the am...

Embodiment 3

[0058] The main uranium-containing minerals in a gravity separation concentrate are niobium-titanium-uranium ore, and the gangue minerals mainly include microplagioclase, calcite, quartz, neonite, albite, biotite, etc., and the grade of uranium is 0.073%.

[0059] (1) The combined collector is prepared according to the ratio that the mass fraction of carbenic acid accounts for 85%, and the mass fraction of butyl xanthate accounts for 15%.

[0060] (2) The combined collector is prepared into an aqueous solution with a mass fraction of 1% with hot water at a temperature of 60°C.

[0061] (3) Grind the fineness of the gravity-selected concentrate to -0.074mm, accounting for 65%, adjust the concentration of the pulp to 30%, and put it into the flotation cell, and adjust the Ph value of the pulp to 5.5 with concentrated sulfuric acid.

[0062] (4) A closed-circuit process of one roughing, one sweeping, and two beneficiation is adopted to flotation the niobium-titanium-uranium ore. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com