Chalcogenide compound, production method thereof and thermoelectric element comprising same

A chalcogen element and compound technology, applied in the field of chalcogen-containing compounds, its preparation and thermoelectric elements containing it, can solve the problems of inability to exhibit phase stability, low thermal conductivity thermoelectric characteristics, poor phase stability, etc. , to achieve the effects of excellent phase stability, low thermal conductivity, and excellent thermoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

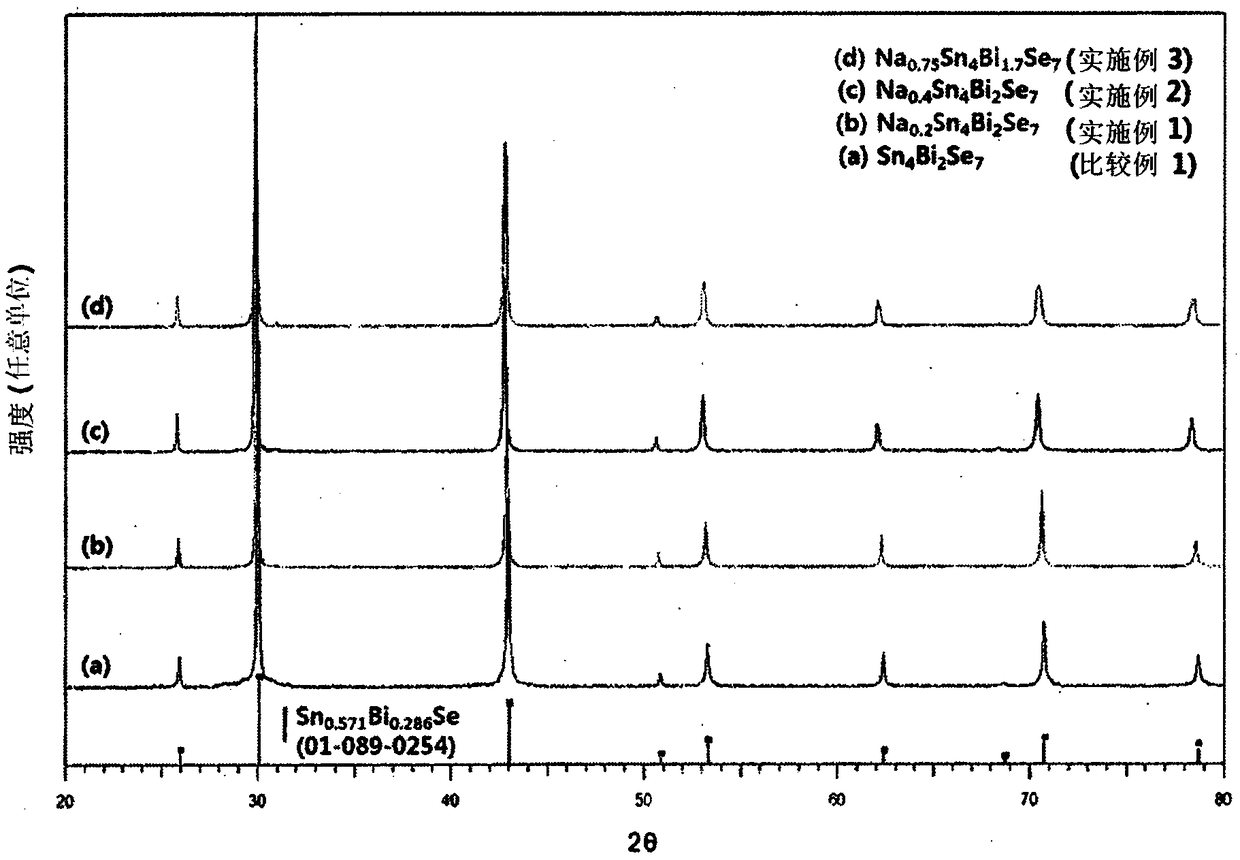

[0072] Embodiment 1: the compound containing chalcogen (Na 0.2 sn 4 Bi 2 Se 7 ) preparation

[0073] Sn, Bi, Se and Na in a molar ratio of 4:2:6.9(7-0.1):0.1 in the glove box 2 The respective high-purity raw material powders of Se were weighed into carbon crucibles and then loaded into quartz tubes. The interior of the quartz tube is evacuated and sealed. The raw materials were kept at a constant temperature in an electric furnace at 620° C. for 24 hours.

[0074] Thereafter, the quartz tube in which the reaction was performed was cooled with water to obtain an ingot, which was finely ground into a powder having a particle diameter of 75 μm or less, and subjected to spark plasma sintering (SPS) at a temperature of 620° C. and a pressure of 50 MPa. Sintering was carried out for 10 minutes to prepare the chalcogen-containing compound Na 0.2 sn 4 Bi 2 Se 7 .

Embodiment 2

[0075] Embodiment 2: the compound containing chalcogen (Na 0.4 sn 4 Bi 2 Se 7 ) preparation

[0076] Prepare chalcogen-containing compound Na by the same method as in Example 1 0.4 sn 4 Bi 2 Se 7 , the difference is that Sn, Bi, Se and Na 2 The respective high-purity raw material powders of Se were mixed in a glove box at a molar ratio of 4:2:6.8(7-0.2):0.2.

Embodiment 3

[0077] Embodiment 3: the compound (Na 0.75 sn 4 Bi 1.7 Se 7 ) preparation

[0078] Prepare chalcogen-containing compound Na by the same method as in Example 1 0.75 sn 4 Bi 1.7 Se 7 , the difference is that Sn, Bi, Se and Na 2 The respective high-purity raw material powders of Se were mixed in a glove box at a molar ratio of 4:1.7:6.625(7-0.375):0.375.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com