Method for preparing high-efficiency filtration and intelligent antibacterial porous nanofiber membrane

A nanofiber membrane, high-efficiency filtration technology, applied in filtration and separation, fiber treatment, separation methods, etc., can solve the problems of fiber morphology damage, increased process difficulty, and difficulty in industrialized production, achieving low resistance, good filtration effect, The effect of promoting swelling and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Example 1 Porous Nanofiber Membrane A

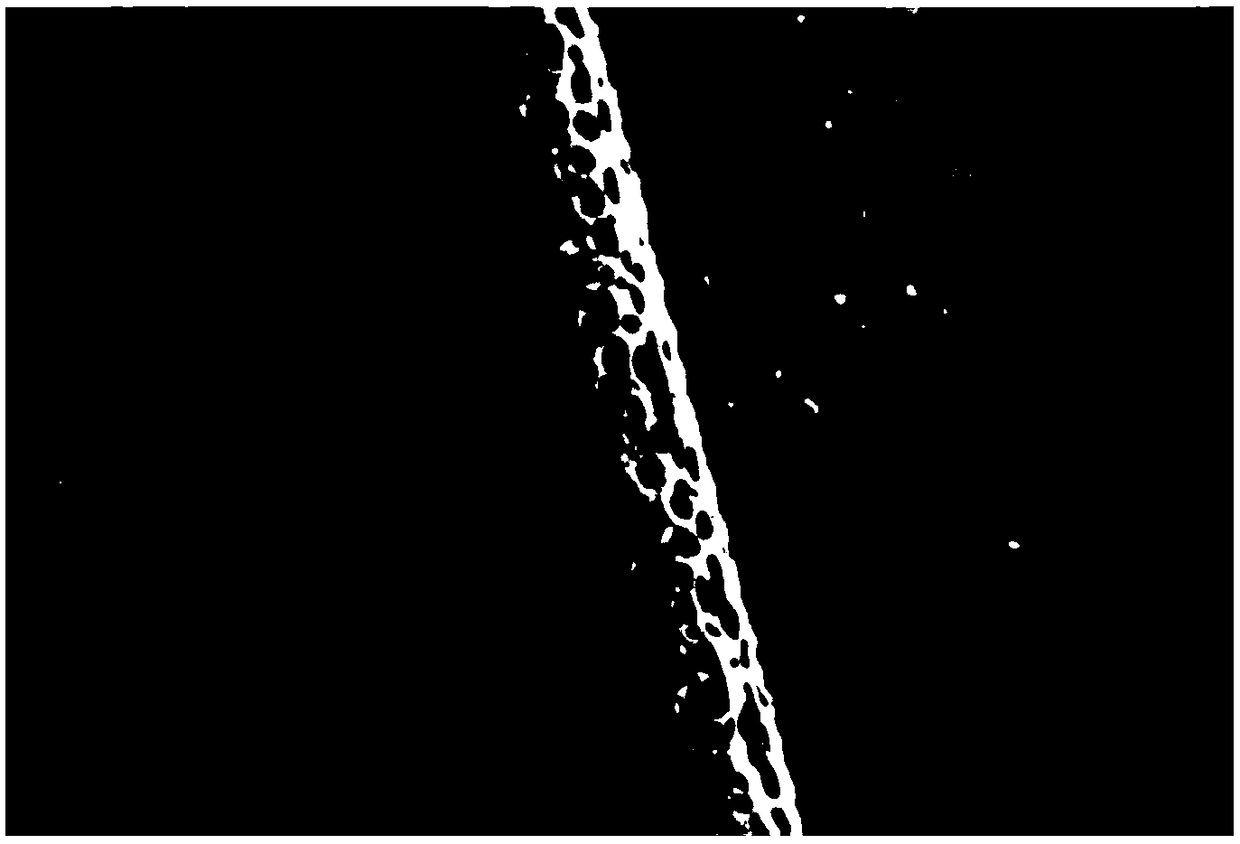

[0026] figure 1 Shown is the SEM image of the porous nanofibers prepared in Example 1.

[0027] PLGA and PCL are dissolved in a mixed solvent of dichloromethane and N.N dimethylformamide according to a mass ratio of 1:1, and the mass fraction of the polymer is 10%; wherein N.N dimethylformamide accounts for 5% of the mixed solvent mass , Stir well, then divide into two bottles, add 3% citric acid to one bottle of solution, add 3% sodium chlorite to the other bottle of solution, and then stir to make it disperse evenly. Adding 2% polyvinyl alcohol microspheres to the two solutions is beneficial to promote the expansion of nanofibers to absorb water and accelerate the reaction; then the solution is at a spinning voltage of 30kv, the spinning distance is 12cm, and the flow rate of the micro-injection pump is 200ml / h at a temperature of 25° C. and a relative humidity of 60% for a period of electrospinning to obtain a...

Embodiment 2

[0028] Preparation of Example 2 Porous Nanofiber Membrane B

[0029] Dissolve PLGA and PCL in dichloromethane according to the mass ratio of 1:2, the mass fraction of the polymer is 11%, fully stir evenly, and then divide into two bottles, add 5% citric acid to the solution in one bottle, and add 5% citric acid in the other bottle Add 4% sodium chlorite and stir to make it evenly dispersed. Adding 3% polyvinyl alcohol microspheres to the two solutions is beneficial to promote the swelling and water absorption of nanofibers and accelerate the reaction; then the solution is at a spinning voltage of 40kv, the spinning distance is 15cm, and the flow rate of the micro-injection pump is 300ml / h at a temperature of 25° C. and a relative humidity of 70% for a period of electrospinning to obtain a porous nanofibrous membrane B. The average diameter of the porous nanofiber is 700nm, and the pore size range is 80-200nm. The intelligent antibacterial efficiency is 98.5%. At an ambient ...

Embodiment 3

[0030] Preparation of Example 3 Porous Nanofiber Membrane C

[0031] Dissolve PLGA and PCL in dichloromethane and N.N dimethylformamide according to the mass ratio of 2:1, the polymer mass fraction is 10%; wherein N.N dimethylformamide accounts for 4% of the mass of the mixed solvent, stir well Evenly, then divide into two bottles, add 9% citric acid to one bottle of solution, add 4% sodium chlorite to the other bottle of solution, and then stir to make it disperse evenly. Adding 2% polyvinyl alcohol microspheres to the two solutions is beneficial to promote the expansion and absorption of nanofibers and accelerate the reaction; then the solution is at a spinning voltage of 50kv, the spinning distance is 20cm, and the flow rate of the micro-injection pump is 500ml / h at a temperature of 25° C. and a relative humidity of 75% for a period of electrospinning to obtain a porous nanofibrous membrane C. The average diameter of the porous nanofiber is 300nm, and the pore size range ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com