Coating applied to marine anchor chain and preparation method of coating

An anchor chain and coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of poor adhesion, high brittleness and low toughness of chlorinated rubber coatings, and achieve good compatibility, few synthesis steps and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

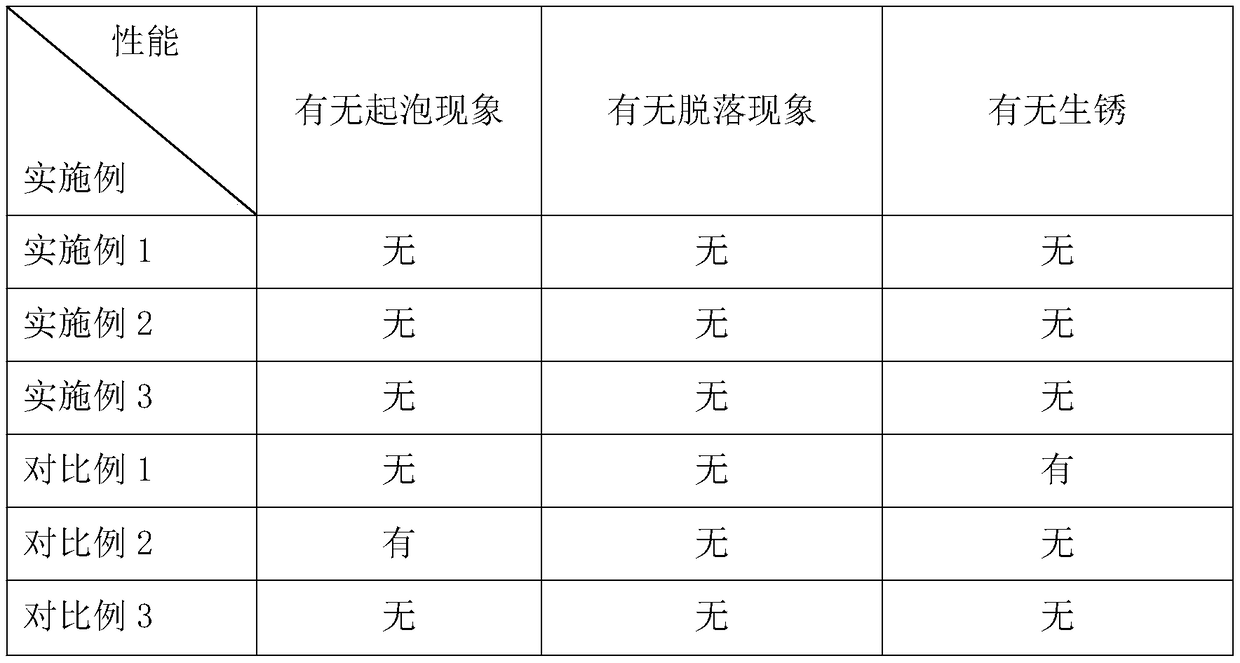

Examples

Embodiment 1

[0015] A coating applied to marine anchor chains, comprising the following components in parts by mass: 28 parts of chlorinated rubber, 23 parts of vinyl acetate resin, 8 parts of aluminum powder, 7 parts of copper chloride, 5 parts of eugenol, and 5 parts of epoxy resin , 2 parts of zinc sulfate, 1 part of talc powder, 4 parts of nano-magnesium hydroxide, 6 parts of anilinomethyltriethoxysilane, 6 parts of polypropylene fiber, 0.5 parts of eucalyptus extract, 8 parts of n-butanol, vinyl benzene 17 parts, 9 parts of casein, 8 parts of m-phenylenediamine, 1.2 parts of defoamer, 3 parts of drier, 1 part of anti-mold and fungicide.

[0016] The drier is naphthenic acid soap or octanoic acid soap.

[0017] The anti-mildew and fungicide is 8-hydroxyquinoline.

[0018] A method for preparing a coating applied to anchor chains for ships, comprising the following steps: the first step, weighing raw materials; the second step, adding nano-magnesium hydroxide to n-butanol, ultrasonical...

Embodiment 2

[0020] A coating applied to marine anchor chains, comprising the following components by mass: 22 parts of chlorinated rubber, 22 parts of vinyl acetate resin, 7 parts of aluminum powder, 3 parts of copper chloride, 4 parts of eugenol, and 3 parts of epoxy resin 1 part of zinc sulfate, 1 part of talc powder, 3 parts of nano-magnesium hydroxide, 4 parts of anilinomethyltriethoxysilane, 5 parts of polypropylene fiber, 0.3 parts of eucalyptus extract, 8 parts of n-butanol, vinyl 16 parts of benzene, 5 parts of casein, 5 parts of m-phenylenediamine, 0.5 part of defoamer, 1 part of drier, 0.05 part of anti-mold and fungicide.

[0021] The drier is naphthenic acid soap or octanoic acid soap.

[0022] The anti-mildew and fungicide is 8-hydroxyquinoline.

[0023] A method for preparing a coating applied to anchor chains for ships, comprising the following steps: the first step, weighing raw materials; the second step, adding nano-magnesium hydroxide to n-butanol, ultrasonically dispe...

Embodiment 3

[0025] A coating applied to marine anchor chains, comprising the following components by mass: 36 parts of chlorinated rubber, 24 parts of vinyl acetate resin, 9 parts of aluminum powder, 8 parts of copper chloride, 8 parts of eugenol, and 8 parts of epoxy resin , 2 parts of zinc sulfate, 4 parts of talc, 5 parts of nano-magnesium hydroxide, 7 parts of anilinomethyltriethoxysilane, 7 parts of polypropylene fiber, 0.6 parts of eucalyptus extract, 9 parts of n-butanol, vinyl 18 parts of benzene, 13 parts of casein, 9 parts of m-phenylenediamine, 1.5 parts of defoamer, 4 parts of drier, 1.5 parts of anti-mold and fungicide.

[0026] The drier is naphthenic acid soap or octanoic acid soap.

[0027] The anti-mildew and fungicide is 8-hydroxyquinoline.

[0028] A method for preparing a coating applied to anchor chains for ships, comprising the following steps: the first step, weighing raw materials; the second step, adding nano-magnesium hydroxide to n-butanol, ultrasonically dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com