Film blowing anti-static adsorption device and thin film cutting-off mechanism

An adsorption device, anti-static technology, applied in thin material handling, transportation and packaging, metal processing, etc., can solve the problems that cannot be effectively solved, the film is prone to static electricity, the equipment cannot work normally, etc., to achieve stable film delivery. , the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

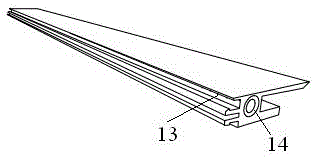

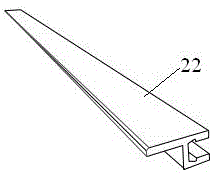

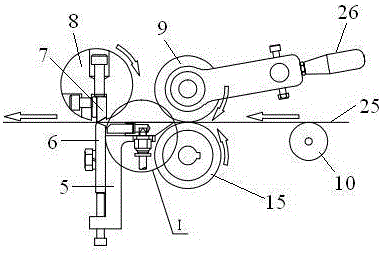

[0019] combine figure 1 , figure 2 , Figure 5 As shown, the blown film anti-static adsorption device of the present embodiment 1 includes a pore guide plate 2, a film-guiding seat plate 1, a straight-through 3, and a gas pipe 4, and the film-guiding seat plate 1 is provided with a gas channel 11 and a hollow groove 12, and the gas channel 11 communicates with the hollow groove 12, and the upper end of the side wall of the hollow groove 12 is provided with a row of ventilation holes 13, and the gas channel 11 is arranged at the lower middle position of the film guide seat plate 1, and the number is one, and the air pipe 4 passes through the direct passage 3 and the gas channel 11 Sealed connection; the air hole guide plate 2 and the film guide seat plate 1 can be fixed together by sliding rails, the air hole guide plate 2 has an upper plane 22, after the air hole guide plate 2 is connected with the film guide seat plate 1, the air holes The upper plane 22 of the guide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com