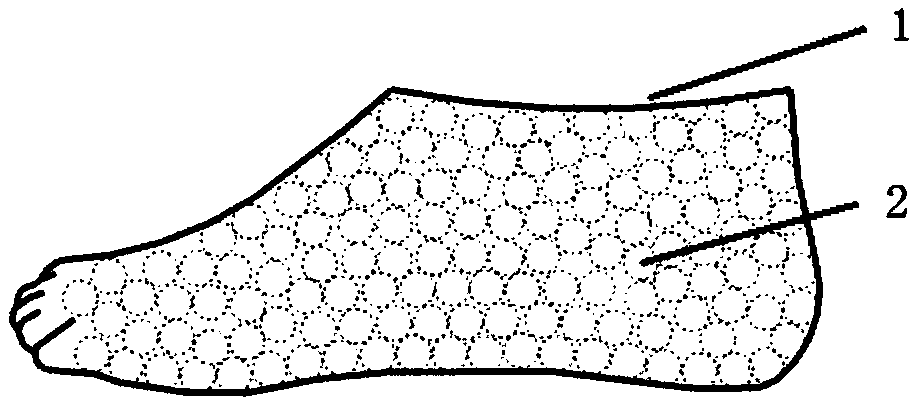

Ultra-light and high resilience bionic prosthesis and forming process thereof

A molding process and high resilience technology, applied in the field of bionic prosthesis and its molding process, can solve the problem that the comfort and mechanical properties of the prosthesis cannot meet the needs of users at the same time, and achieve the inhibition of bacterial growth, good low temperature performance, and mechanical properties. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The molding process of the ultra-light and high-resilience bionic prosthesis of this embodiment is as follows:

[0032] When synthesizing the TPU raw materials, add 0.5% of the component flesh-colored powder and 2% of the antibacterial agent, and the rest is TPU, selected from polyether polyurethane. After mixing, it is synthesized and granulated to prepare a TPU composite material. The TPU composite material particles are obtained by down-cutting, and the particle size is controlled at about 3mm.

[0033] Put the TPU composite material particles into a supercritical carbon dioxide permeation kettle, pass in carbon dioxide and pressurize, so that the pressure reaches 10Mpa and the temperature is 35°C. At this time, the carbon dioxide is in a supercritical state. In this state, pressurize and infiltrate for 3 hours, quickly release the pressure and heat to about 130°C, at this time, the TPU composite material is foamed to obtain E-TPU composite material foamed particles....

Embodiment 2

[0040] The molding process of the ultra-light and high-resilience bionic prosthesis of this embodiment is as follows:

[0041] When synthesizing the TPU raw materials, add 3% of the flesh-colored powder and 1% of the antibacterial agent, and the rest is TPU. TPU composite material particles are obtained by underwater pelletizing, and the particle size is controlled at about 4mm.

[0042] Put the TPU composite material particles into a supercritical carbon dioxide permeation kettle, pass in carbon dioxide and pressurize, so that the pressure reaches 7.38Mpa and the temperature is 35°C. At this time, the carbon dioxide is in a supercritical state. In this state, pressurize and infiltrate for 1 hour, quickly release the pressure and heat to about 130°C, at this time, the TPU composite material is foamed to obtain E-TPU composite material foamed particles. Put the foamed particles into steam molding equipment for steam molding. The steam pressure is controlled at 0.3MPa, the stea...

Embodiment 3

[0044] The molding process of the ultra-light and high-resilience bionic prosthesis of this embodiment is as follows:

[0045] When synthesizing the TPU raw materials, add 3% of the flesh-colored powder and 2.5% of the antibacterial agent, and the rest is TPU. The TPU is selected from polyether polyurethane and / or polyester polyurethane. After mixing, it is synthesized and granulated. The TPU composite material is prepared, and the TPU composite material particles are obtained by underwater pelletizing, and the particle size is controlled at about 4 mm.

[0046] Put the TPU composite material particles into a supercritical carbon dioxide permeation kettle, pass in carbon dioxide and pressurize, so that the pressure reaches 15Mpa and the temperature is 31°C. At this time, the carbon dioxide is in a supercritical state. In this state, pressurize and infiltrate for 3 hours, quickly release the pressure and heat to about 130°C, at this time, the TPU composite material is foamed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com