Method for making unbaked ceremsite from phosphogypsum

A technology of phosphogypsum and ceramsite, which is applied in the field of phosphogypsum to make non-fired ceramsite, which can solve the problems of environmental hazards, low utilization of phosphogypsum, low utilization rate, etc., achieve less equipment and labor investment, and reduce production and production costs , The effect of simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

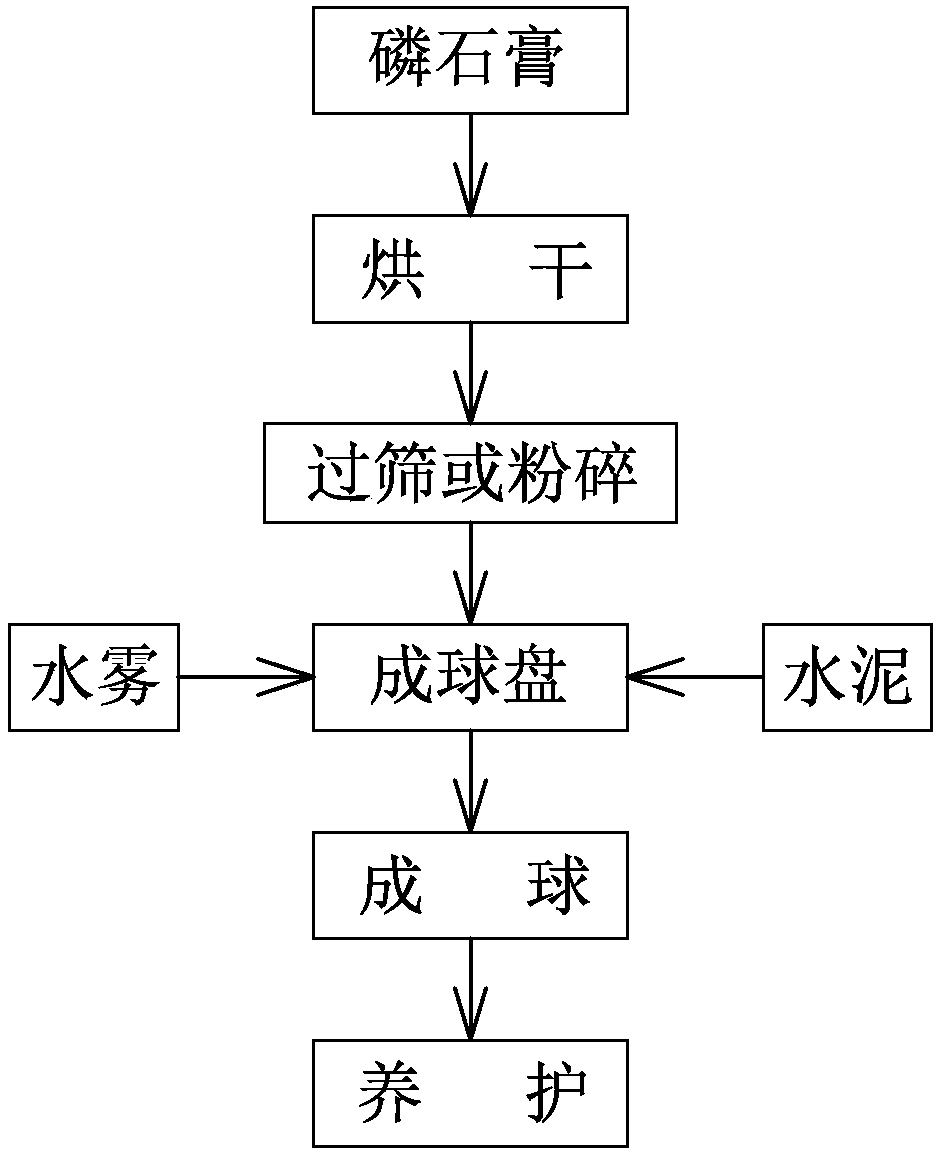

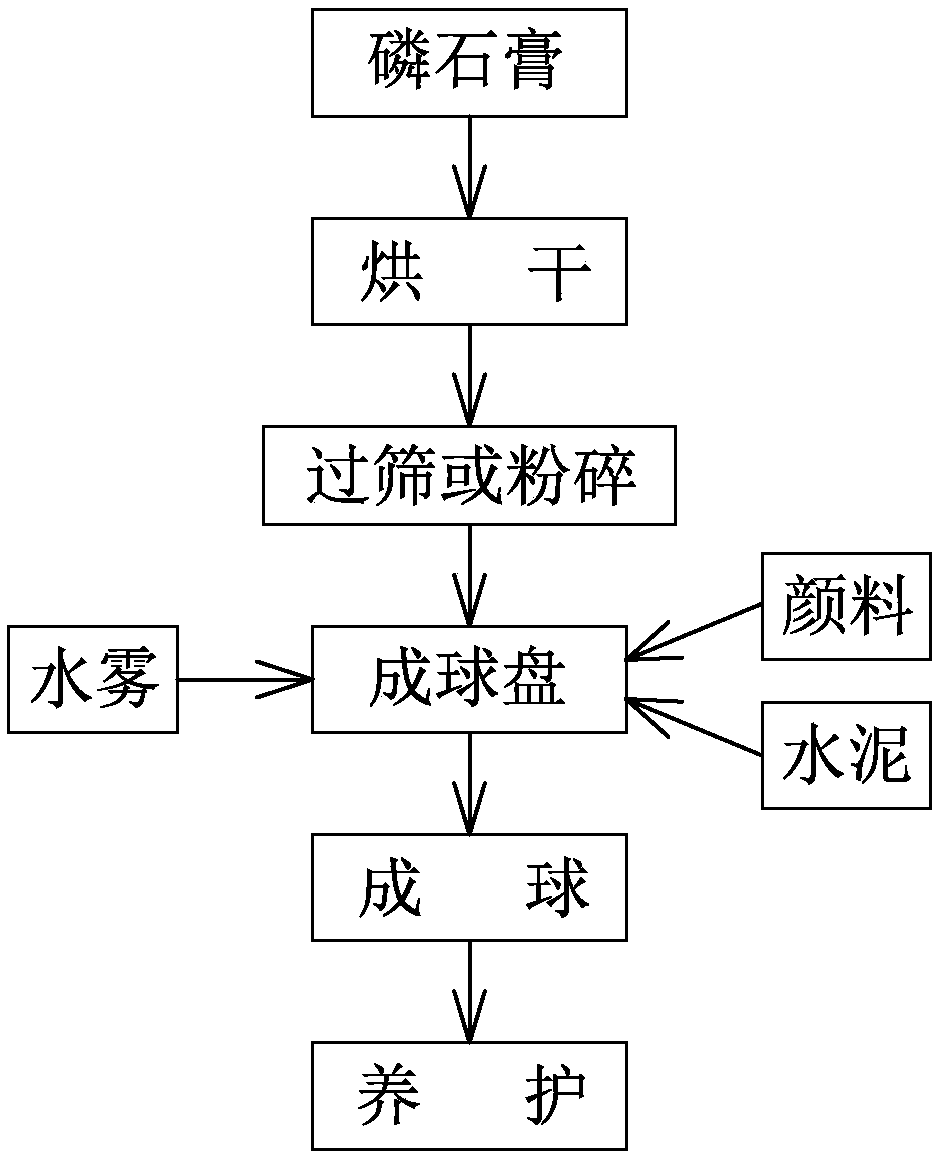

[0015] Now in conjunction with accompanying drawing, the present invention will be further described.

[0016] Such as figure 1 As shown, the method for making unfired ceramsite from this phosphogypsum is as follows: after drying the phosphogypsum with a water content of 20%-30%, it is sieved or crushed to form a powder, and the phosphogypsum powder and cement are measured and mixed evenly After that, it is transported to the pelletizing disk by the conveyor, and the pelletizing disk rotates clockwise. The phosphogypsum powder and cement move in the opposite direction relative to the pelletizing disk under the action of the scraper machine of the pelletizing disk, and simultaneously with the rotation of the pelletizing disk. Spray water mist, make phosphogypsum powder and cement into balls, and transport them to Pingku through a belt conveyor to stack for natural curing for 72-120 hours, and then make unfired ceramsite products. In the above method, the ratio of phosphogypsum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com