High ammonia-nitrogen wastewater treatment method based on forced throttling and ultrasonic treatment

A technology for wastewater treatment and high ammonia nitrogen, applied in water treatment parameter control, degassed water/sewage treatment, neutralized water/sewage treatment, etc. Scale and scale deposits, reducing the possibility of scaling, improving the effect of ammonia nitrogen removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

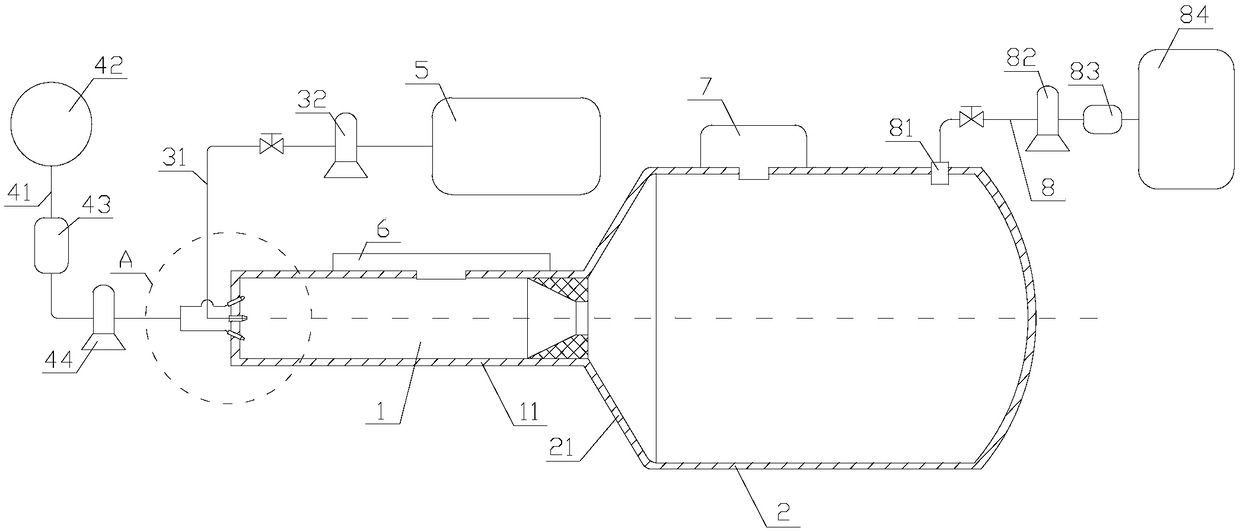

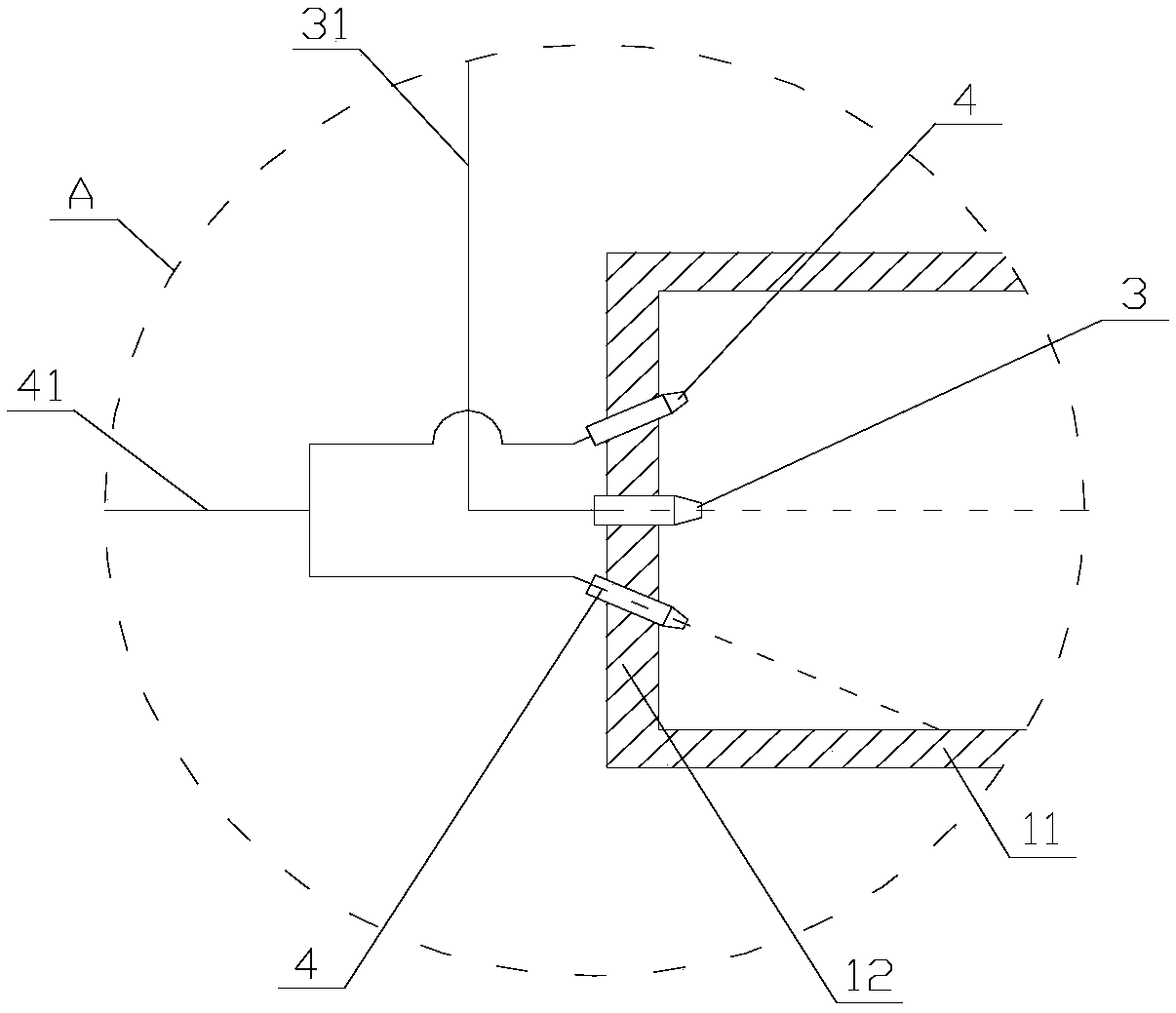

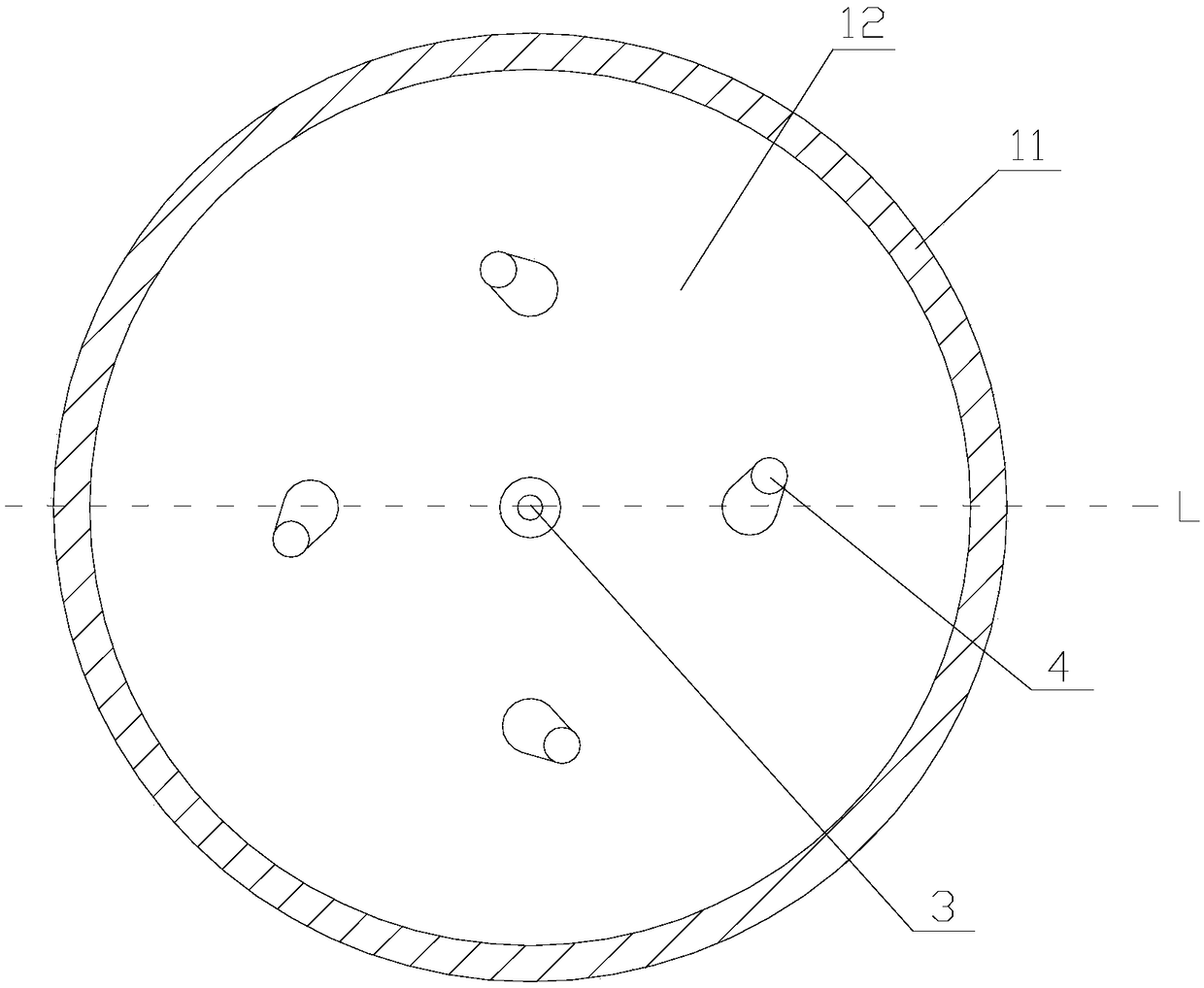

[0040] Such as Figure 1-3 As shown, the method for treating high ammonia nitrogen wastewater based on forced throttling and ultrasonic treatment of the present invention includes the following steps:

[0041] 1) The high ammonia nitrogen wastewater is pressurized and mixed with gas, and then passed into a throttling device 2;

[0042] 2) Using ultrasound to act on the mixture of high ammonia nitrogen wastewater and gas in the throttling device 2;

[0043] 3) The air extraction device 8 is used to extract the throttled and ultrasonically treated mixture from the throttle device 2 from the throttle device 2.

[0044] Wherein, in step 1), the pressurized high ammonia nitrogen wastewater is mixed with gas, and the gas-liquid ratio is 1000:1 to 1500:1.

[0045] Further, in step 1), the gas is air or nitrogen, and the gas temperature is 45-80°C. Before the high ammonia nitrogen wastewater is pressurized and mixed with the gas, NaOH solution and steam are added to the high ammonia wastewater...

Embodiment 2

[0051] Such as Figure 1-3 As shown, the method for treating high ammonia nitrogen wastewater based on forced throttling and ultrasonic treatment of the present invention includes the following steps:

[0052] 1) The high ammonia nitrogen wastewater is pressurized and mixed with gas, and then passed into a throttling device 2;

[0053] 2) Using ultrasound to act on the mixture of high ammonia nitrogen wastewater and gas in the throttling device 2;

[0054] 3) The air extraction device 8 is used to extract the throttled and ultrasonically treated mixture from the throttle device 2 from the throttle device 2.

[0055] Wherein, in step 1), the pressurized high ammonia nitrogen wastewater is mixed with gas, and the gas-liquid ratio is 1000:1 to 1500:1.

[0056] Further, in step 1), the gas is air or nitrogen, and the gas temperature is 45-80°C. Before the high ammonia nitrogen wastewater is pressurized and mixed with the gas, NaOH solution and steam are added to the high ammonia wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com