Liquid-state CO2 washing method of petroleum industry oil dirt equipment and facilities

A technology for oil industry and oil pollution, which is applied in the field of liquid CO2 cleaning of oil pollution equipment and facilities in the oil industry. The effect of recycling and simple conveying device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

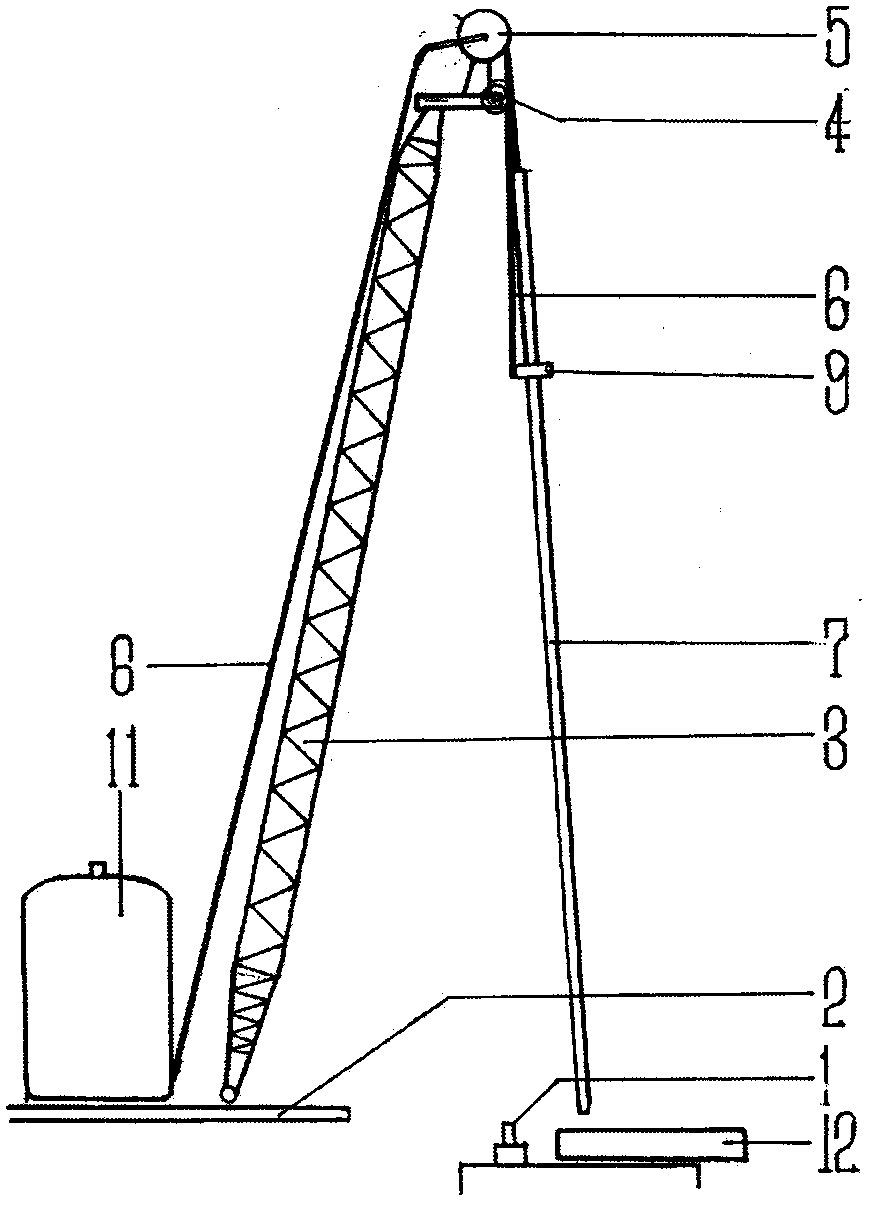

[0028] The present invention will be described in further detail below in conjunction with the example of workover operation shown in the accompanying drawings:

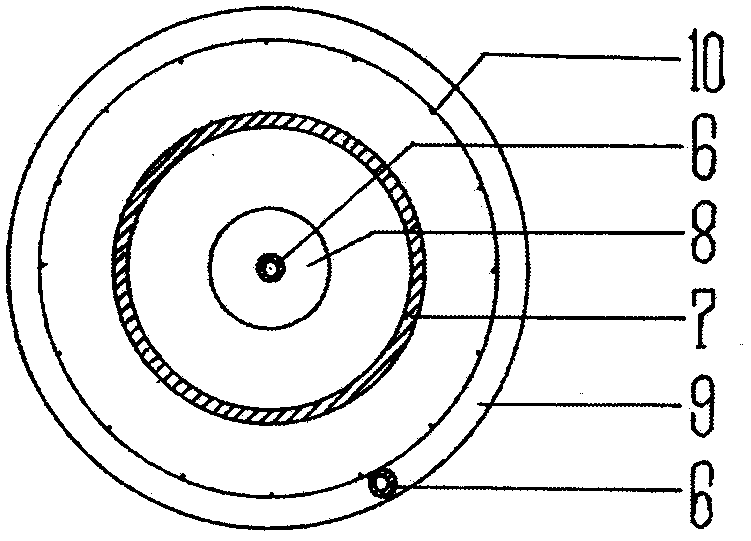

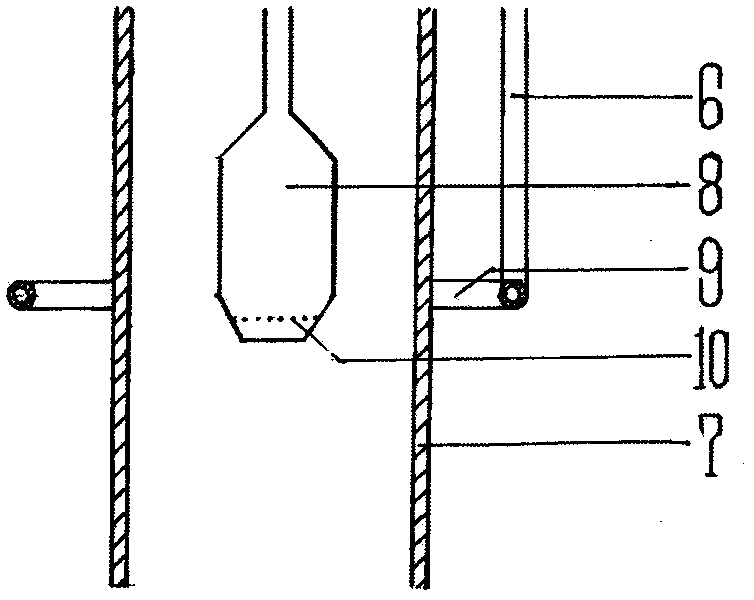

[0029] Such as figure 1 As shown: the workover operation needs to pass the pulley 4 at the top of the tower 3 provided on the workover vehicle platform 2, and the sucker rod and the oil well pipe 7 are hoisted out section by section by the wellhead 1. For sucker rods immersed in oil wells with a large amount of oil stains on the outside and oil well pipes 7 with a lot of oil stains on the inner and outer walls, after being lifted from the wellhead 1, they are pulled obliquely above the oil receiving groove 12, and the sucker rods pass through the annular centripetal jet Nozzle 9 emits liquid CO from capstan 5 2 The delivery pipeline 6 is from top to bottom, and the liquid CO injected by the downward-sloping jet hole 10 2 Rapid and thorough peeling from top to bottom to remove sticky and oil stains. The oil well pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com