Industrial silicon electric furnace electrode arrangement and configuration structure

A technology of electric furnace electrodes and industrial silicon, which is applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problems that the production equipment cannot meet the needs of the industry, it is difficult to realize normal production at full load, and other electrode breakage accidents, etc., to achieve increased Effects of factory benefits, reduction of dead angles in the furnace, and reduction of electric furnace accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

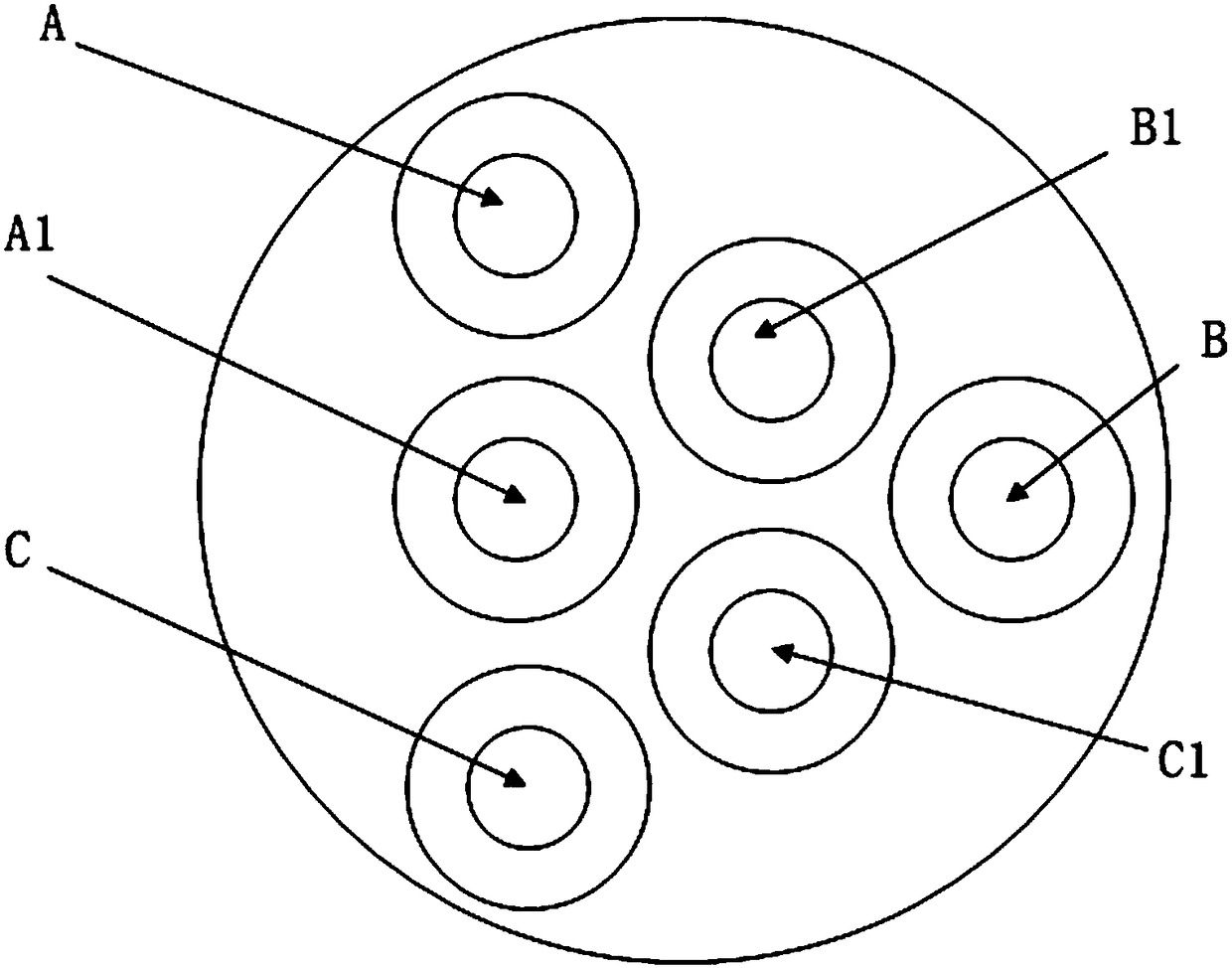

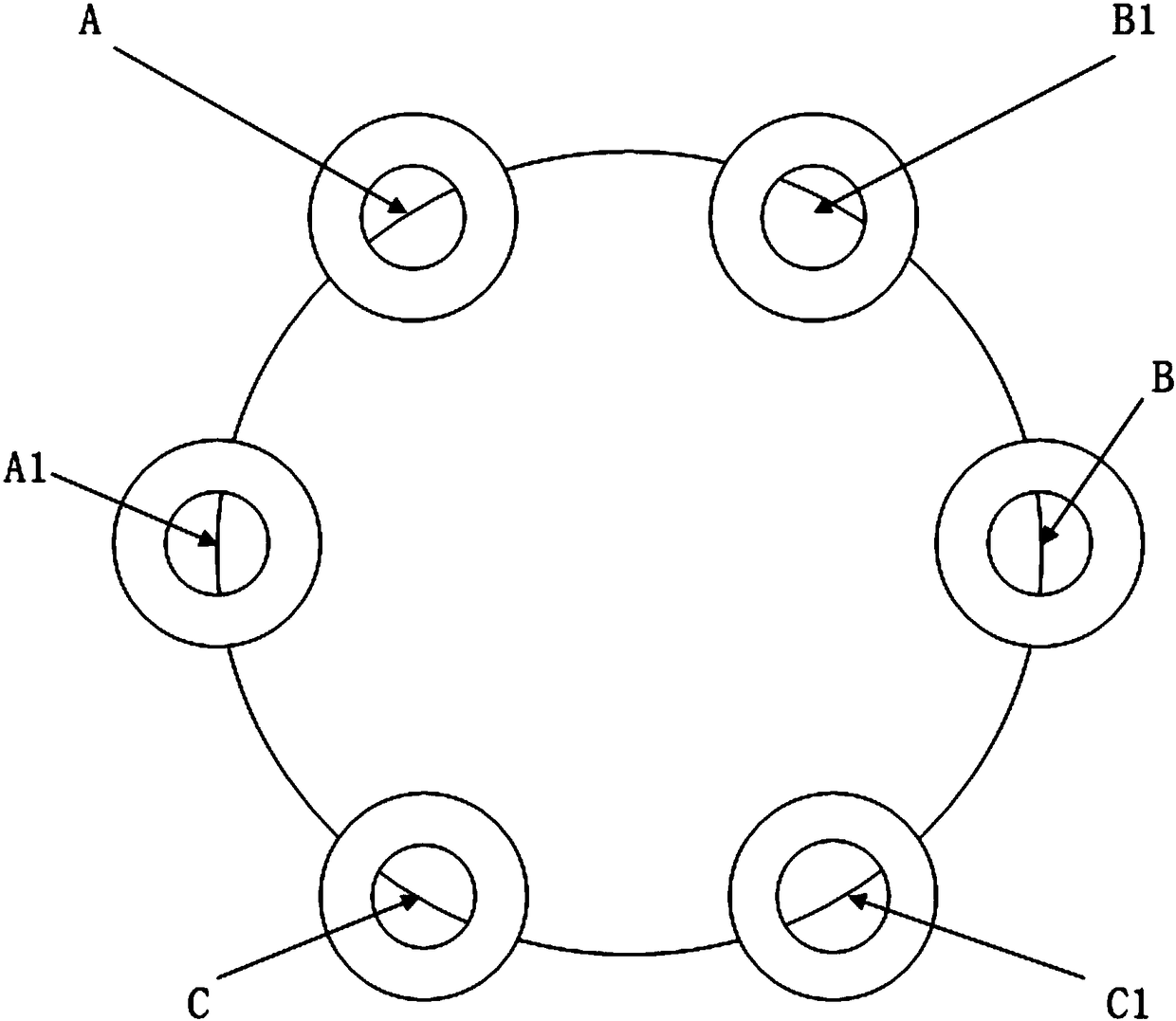

[0021] See figure 1 , the first set of electrodes A, B, and C of the present invention have equal spacing to form an equilateral triangle layout, and form the three outer triangles A, B, and C with equal distances from the inner wall of the electric furnace;

[0022] The newly added second group of electrodes A1, B1, and C1 form the second group. Keep the distance between A1, B1, and C1 equal to form an equilateral triangle layout, forming an inner triangle. The electrodes A1, B1, and C1 are respectively connected to the electric furnace. The distances of the inner walls are equal; the regular triangle formed by the electrodes A, B, C and the regular triangle formed by the electrodes A1, B1, C1. The three-item and inner-outer two-group electrode layout formed in this way makes the distribution of electrodes in the electric furnace more uniform. During the production process, when the electric furnace body rotates, it can effectively break the arching phenomenon of the inner f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com