Process for dyeing and finishing swimsuit fabrics

A technology for fabrics and swimwear, applied in the field of dyeing and finishing of swimwear fabrics, can solve the problems of cumbersome operation and no dyeing and finishing process of swimsuit fabrics, and achieve the effect of good work stability and avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

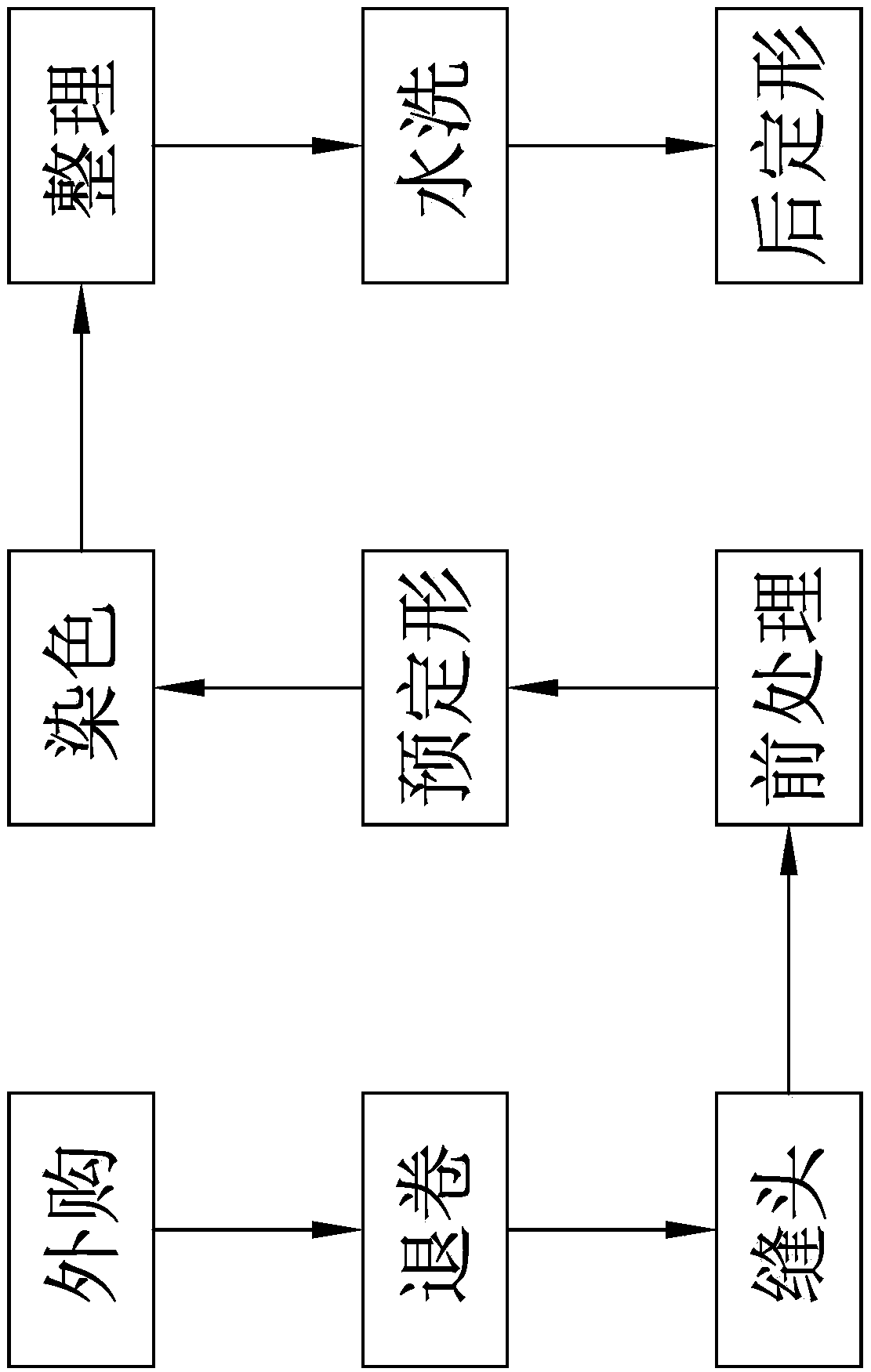

[0068] Such as figure 1 Shown, the dyeing and finishing process of this swimsuit fabric comprises the following steps:

[0069] a. Outsourcing: purchase existing warp-knitted fabrics on the market, which are interwoven with PBT fibers and PET fibers;

[0070] b. Unwinding: put the warp knitted fabric on the unwinding machine for unwinding;

[0071] c. Seam head: connect multiple volumes of warp-knitted fabrics through the seam head machine;

[0072] d, pre-processing; in the present embodiment, what pre-processing adopts is prior art;

[0073] e. Pre-shaping: Pre-shaping the warp-knitted fabric through a shaping machine;

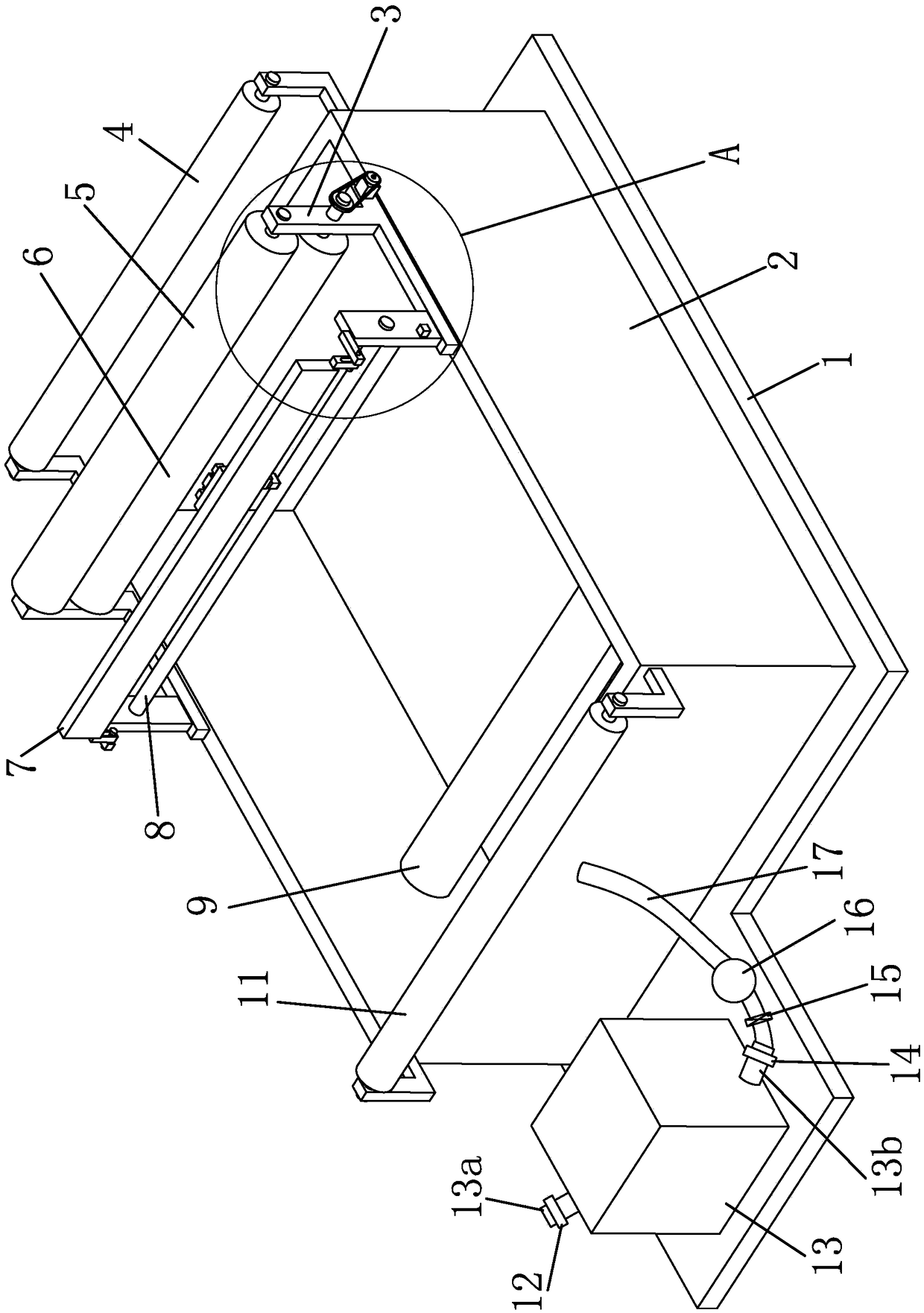

[0074] f. Dyeing: put the warp knitted fabric into the dyeing device, and use disperse dyes for dyeing; use an oven to dry after dyeing;

[0075] g. Finishing: use padding equipment to pad the warp knitted fabric with finishing agent; after padding is completed, use an oven to dry;

[0076] h, washing: put the warp knitted fabric into the washing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com