Preparation method of ginseng chelating peptide

A technology of chelated peptide and ginseng, applied in the field of preparation of ginseng chelated peptide, can solve the problems of low purity of ginseng peptide, difficult to control molecular weight, low extraction rate, etc., to improve the degree of hydrolysis, shorten the hydrolysis time, and improve the conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

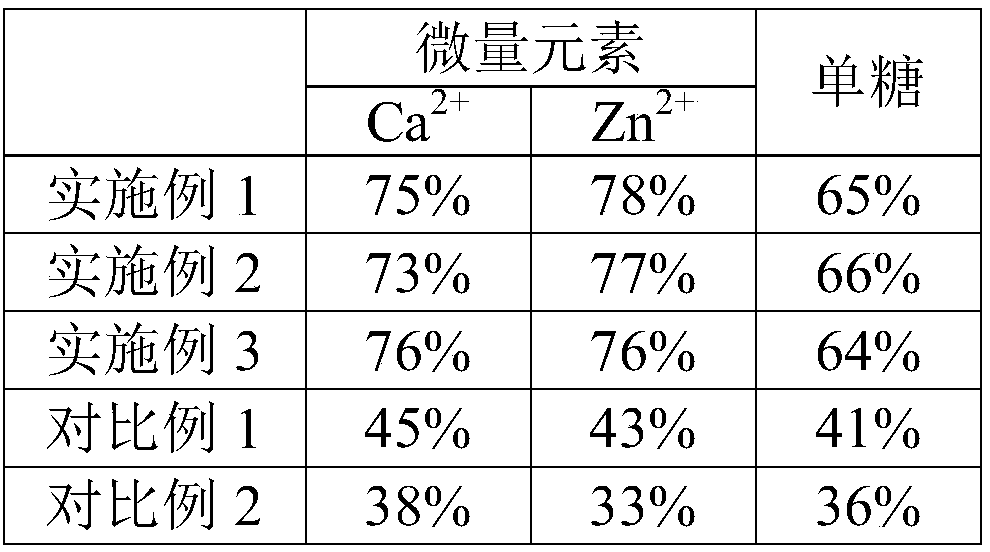

Embodiment 1

[0034] The embodiment of the present invention provides a kind of preparation method of ginseng chelating peptide, comprises the following steps:

[0035] Step a. Slice 100g of ginseng, add 700mL of purified water and stir evenly, decoct at 90°C for 4 hours, then lower the temperature to 55°C, add 1g of amylase and 0.5g of glucoamylase for enzymatic hydrolysis of desugar, enzymatic hydrolysis time 30min;

[0036] Step b. Add 1 g of Bacillus subtilis neutral protease and 0.5 g of bromelain to the enzymolysis solution obtained in step a for enzymolysis. After enzymolysis, heat up to 90° C. and keep for 10 minutes to inactivate the enzyme to obtain a hydrolyzate, wherein the enzymolysis The conditions are: the enzymolysis temperature is 55°C, and the enzymolysis time is 3h;

[0037] Step c, the above-mentioned hydrolyzate is filtered by a decanter centrifuge with a rotating speed of 3600rpm, and the obtained filtrate is centrifugally purified by a three-phase centrifuge with a r...

Embodiment 2

[0040] The embodiment of the present invention provides a kind of preparation method of ginseng chelating peptide, comprises the following steps:

[0041] Step a. Slice 10Kg of ginseng, add 75L of purified water and stir evenly, decoct at 92°C for 4.5h, then lower the temperature to 56°C, add 120g of amylase and 60g of glucoamylase respectively for enzymatic desugar hydrolysis, enzymatic hydrolysis time 35min;

[0042] Step b. Add 120g of Bacillus subtilis neutral protease and 60g of bromelain to the enzymolysis solution obtained in step a for enzymolysis. After enzymolysis, heat up to 92°C and keep for 12 minutes to inactivate the enzyme to obtain a hydrolysis solution. The enzymolysis conditions For: the enzymatic hydrolysis temperature is 56°C, and the enzymatic hydrolysis time is 3.5h;

[0043]Step c, the above-mentioned hydrolyzate is filtered by a decanter centrifuge with a rotating speed of 3600rpm, and the obtained filtrate is centrifugally purified by a three-phase c...

Embodiment 3

[0046] The embodiment of the present invention provides a kind of preparation method of ginseng chelating peptide, comprises the following steps:

[0047] Step a. Slice 100Kg of ginseng, add 800L of purified water and stir evenly, decoct at 95°C for 5 hours, then lower the temperature to 58°C, add 1.5Kg of amylase and 800g of glucoamylase to carry out enzymatic hydrolysis of sugar, enzymatic hydrolysis time 30min;

[0048] Step b. Add 1.5Kg Bacillus subtilis neutral protease and 800g bromelain to the enzymolysis solution obtained in step a for enzymolysis. After enzymolysis, heat up to 95°C and keep for 15 minutes to inactivate the enzyme to obtain a hydrolyzate, wherein the enzymolysis The conditions are: the enzymatic hydrolysis temperature is 58°C, and the enzymatic hydrolysis time is 4h;

[0049] Step c, the above-mentioned hydrolyzate is filtered by a decanter centrifuge with a rotating speed of 3600rpm, and the obtained filtrate is centrifugally purified by a three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com