Acrylic resin and preparation method and application thereof

A technology of acrylic resin and acrylate, which is applied in coatings, polyurea/polyurethane coatings, etc., and can solve problems such as poor mechanical properties and water resistance, low VOC content, poor water resistance and mechanical properties of coating films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

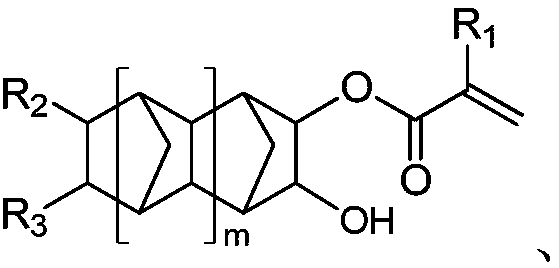

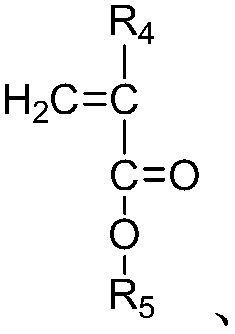

[0086] The acrylic resin 1 that this preparation example obtains is made up of following structural unit:

[0087]

[0088] where n 1 is 10, n 2 is 40, n 3 is 15, n 4 is 10, namely n 1 / n 0 is 0.13.

[0089] The preparation method of acrylic resin is as follows:

[0090] (1) Solution polymerization: put 60% of the total amount of propylene glycol monomethyl ether into a reactor equipped with a stirring device, a condenser, a temperature control system and a monomer dropping device, slowly heat up to the boiling point of the solvent, and start dripping after reflux add Methyl methacrylate, butyl acrylate, 2-ethylhexyl methacrylate, hydroxyethyl methacrylate, acrylic acid, remaining 40% propylene glycol monomethyl ether, 75% tert-butyl peroxybenzoate And the mixed solution of mercaptoethanol is added dropwise within 5 hours, kept warm for 1 hour, added the remaining 25% tert-butyl peroxybenzoate, kept warm for 1 hour, and stopped heating to obtain a hydroxyacrylate co...

preparation example 2

[0096] The difference with Preparation Example 1 is that in acrylic resin 2 n 1 is 1, n 2 is 55, n 3 is 25, n 4 is 20, namely n 1 / n 0 is 0.01.

preparation example 3

[0098] The difference with Preparation Example 1 is that the n in acrylic resin 3 1 is 16, n 2 is 40, n 3 is 15, n 4 is 10, namely n 1 / n 0 is 0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com