Nitrogen resource heat-extraction recovery method

A recovery method and heat extraction technology, applied in chemical instruments and methods, nitrogen fertilizer, heating water/sewage treatment, etc., can solve the problems of poor resistance to water volume and water quality impact load, unstable effluent water quality, etc., to save carbon sources, Significant economic and social benefits of the project, and the effect of reducing nitrogen load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

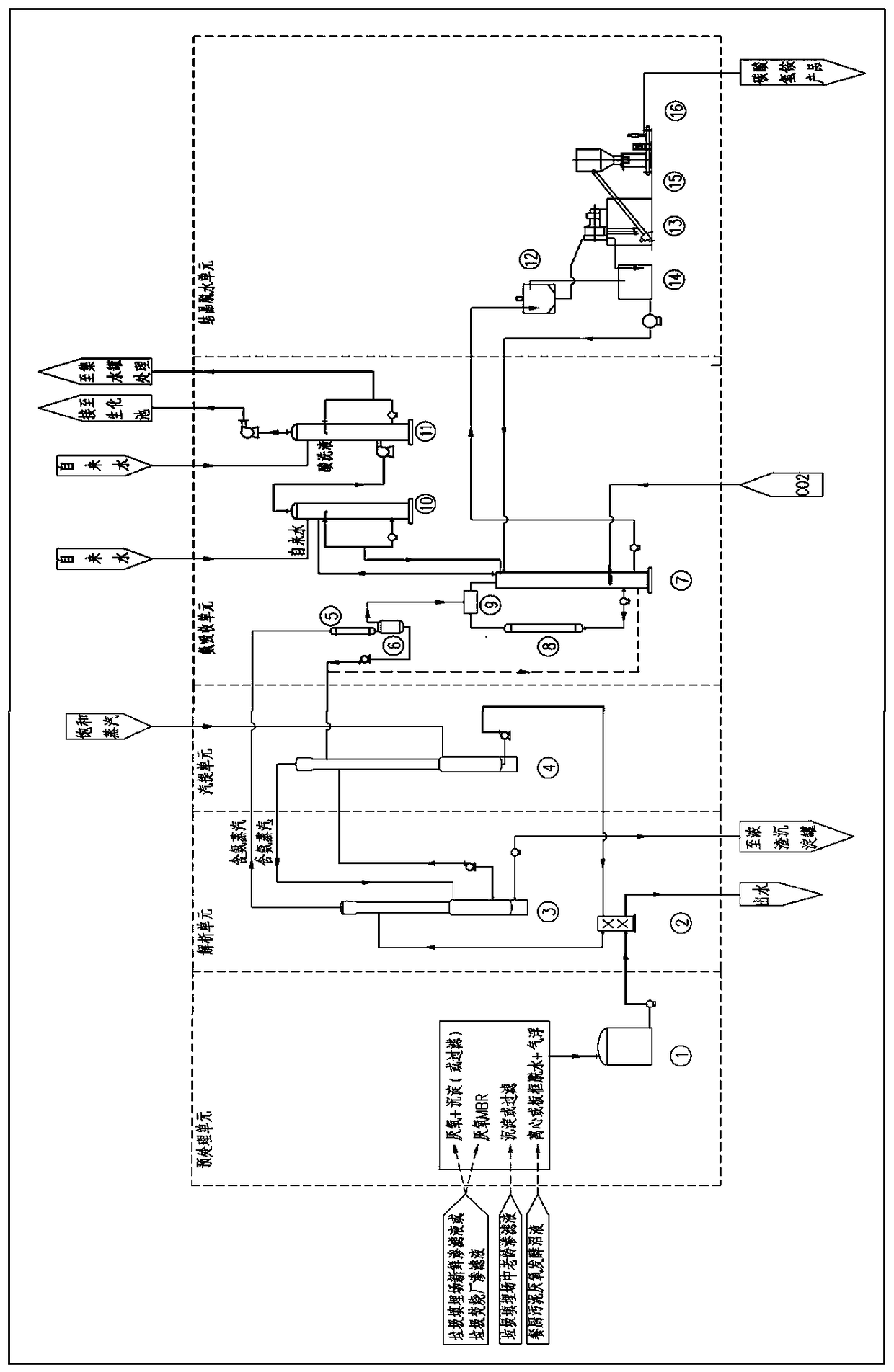

[0026] See figure 1 , figure 1 It shows the process flow of stripping and deamination treatment of aged landfill leachate, in which:

[0027] Pretreatment unit, fresh leachate from landfill or leachate from waste incineration plant adopts anaerobic + sedimentation (or filtration) pretreatment or anaerobic MBR pretreatment, old leachate in landfill adopts sedimentation or filtration pretreatment; The anaerobic fermentation biogas slurry of kitchen sludge is dehydrated by centrifugation or plate and frame, and the dehydrated filtrate is pretreated by air flotation. The purpose is to control the COD≤10000mg / L and SS≤1000mg / L entering the subsequent unit. The leachate or biogas slurry treated by the pretreatment unit is stored in the balance tank 1 and lifted to the analysis unit by the sewage pump.

[0028] The analysis unit is connected to the pretreatment unit, and the analysis unit includes a preheater 2, an analysis reaction tower 3, a thick slag sedimentation tank, a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com