Method for preparing hydrazine from urine

A technology for urine and raw materials is applied in the field of preparing hydrazine by using urine as a raw material, which can solve problems such as affecting the competitiveness of hydrazine hydrate in a urea process, and achieve the effects of reducing nitrogen load, reducing costs and high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] According to the processing parameter of table 1, adopt following steps to prepare the method for hydrazine with urine as raw material, comprise the steps:

[0035] (1) preparation of sodium hypochlorite-sodium hydroxide solution: feed chlorine into sodium hydroxide solution, make sodium hypochlorite-sodium hydroxide solution, make the mol ratio of sodium hypochlorite and sodium hydroxide in the sodium hypochlorite-sodium hydroxide solution be 1: 2;

[0036] (2) Low-temperature reaction: Add sodium hypochlorite-sodium hydroxide solution into fresh urine so that the molar ratio of urea, sodium hypochlorite, and sodium hydroxide in the reaction system is 1.05:1:2; keep stirring, the reaction temperature is 15°C, and the reaction time 30min;

[0037] (3) High-temperature reaction: After the reaction is completed, the material is transferred into a reaction kettle and rapidly heated to boiling, and discharged after reflux for 5 minutes to obtain hydrazine.

[0038] Measur...

Embodiment 2-17

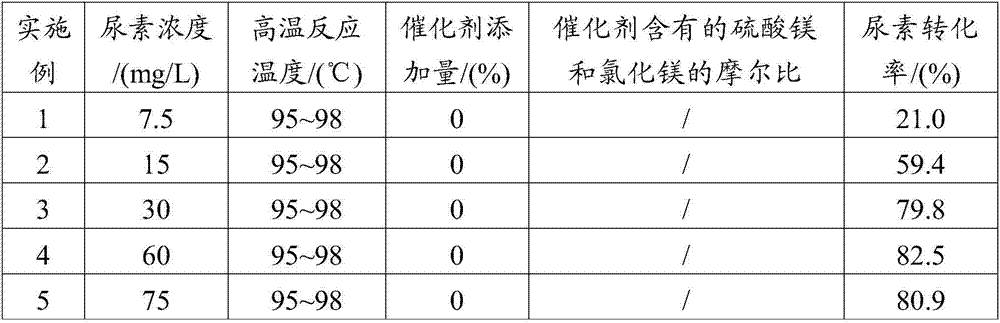

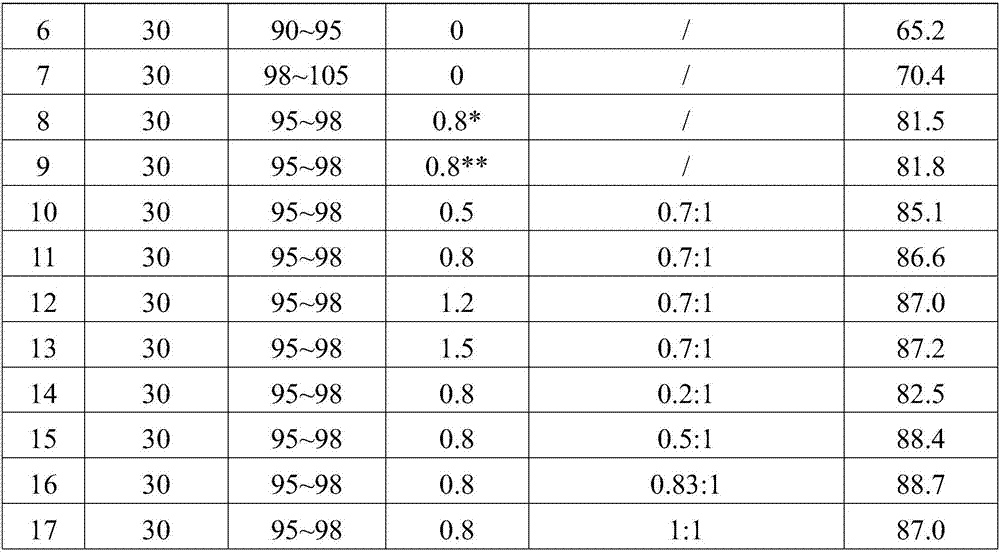

[0041] Except for the contents shown in Table 1, Examples 2 to 17 were performed in a similar manner to Example 1, and the yield of hydrazine was calculated.

[0042] Table 1 process parameter and the productive rate of hydrazine

[0043]

[0044]

[0045] Note: in embodiment 8, catalyzer is magnesium sulfate; In embodiment 9, catalyzer is magnesium chloride.

[0046] When the concentration of urea in urine is 15g / L, the conversion rate of urea is 59.4%, and the yield of hydrazine reaches 3.18g (hydrazine) / L (urine). It can be seen from Table 1 that with the increase of urea concentration in the reaction system, the urea conversion rate is on the rise, and after the urea concentration reaches 30g / L, the urea conversion rate is stable at about 80%. At this time, continue to increase the urea concentration, urea The conversion rate did not change significantly. Compared with Examples 1-5, the conversion rate of urea is obviously increased after using the additive. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com