Electrified repair film material controllable in surface potential and preparation method thereof

A charged repair and surface potential technology, which is applied in the fields of pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problems of inability to adapt to the physiological electric microenvironment, the uncontrollable surface potential of materials, and the limited repair effect of materials, etc., to achieve good bone health. Defect repair effect, good bone repair effect, stable product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

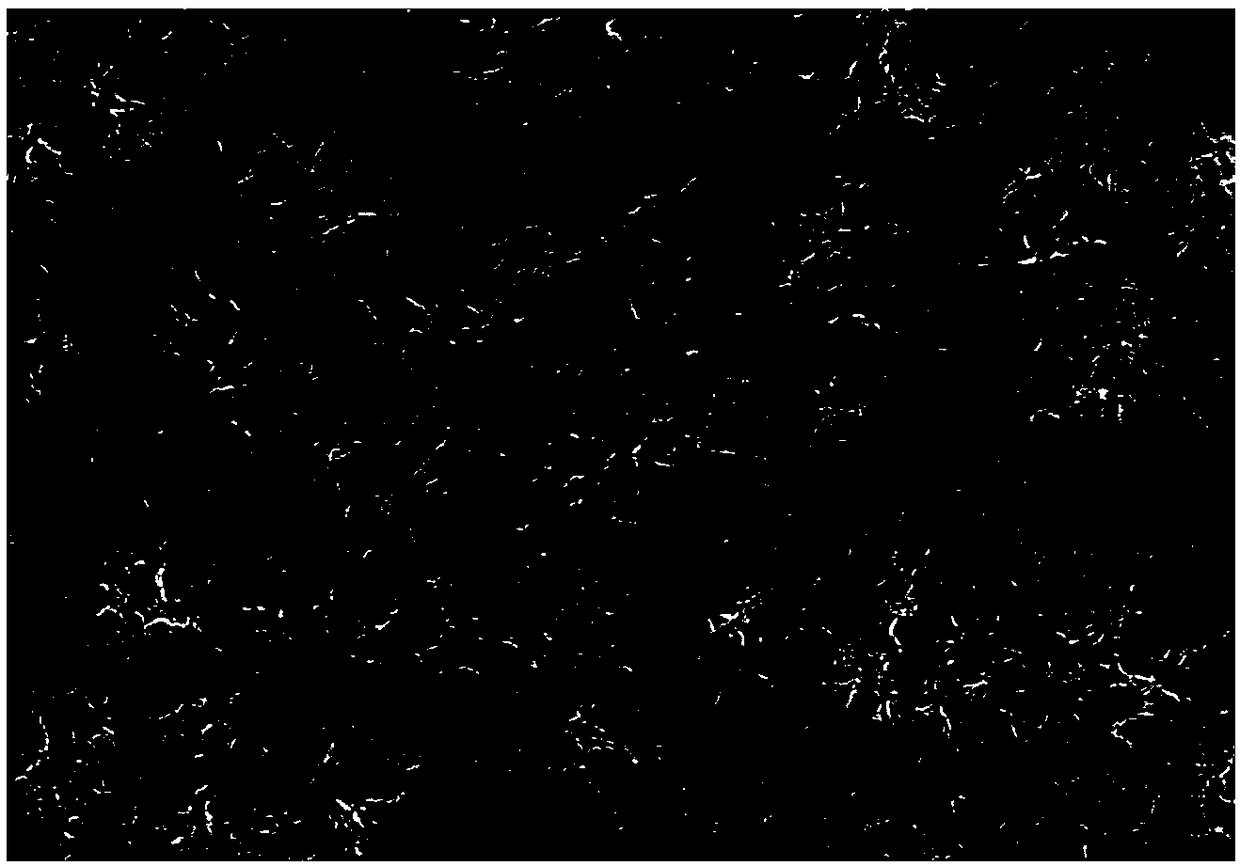

[0026] (1) Weigh 2g of polymer P(VDF-TrFE), add it to 20ml of nitrogen-nitrogen dimethylformamide, make the concentration of the polymer solution 0.1g / ml, place it on a magnetic stirrer and stir for 6h, and make the polymer Uniformly dissolved and dispersed in an organic solvent to obtain a ferroelectric polymer solution;

[0027] (2) casting the mixed solution obtained in step (1) in a casting machine, and drying the film obtained by casting at a temperature of 55° C. to obtain a polymer film material with a film thickness of 70 μm;

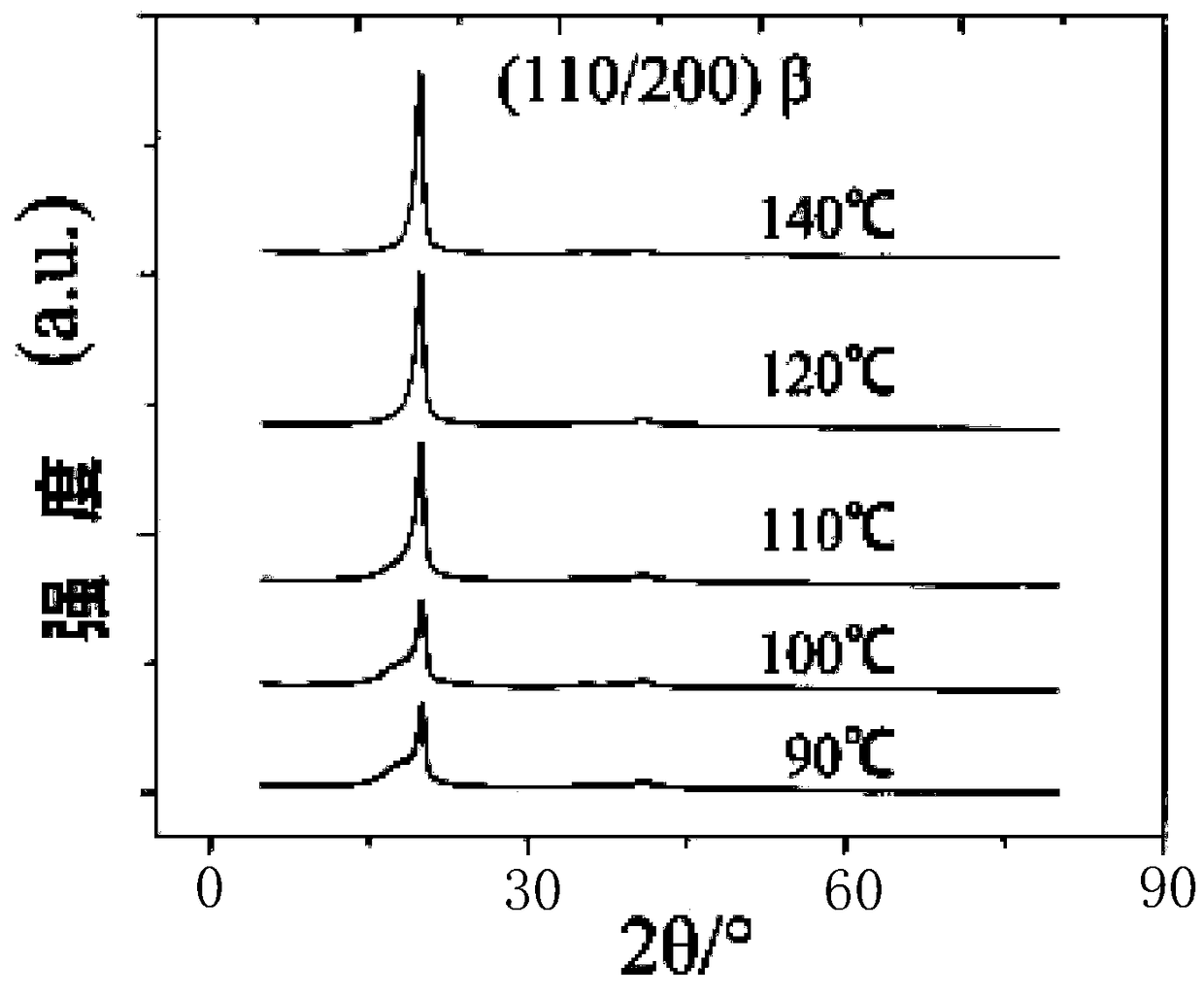

[0028] (3) annealing the film material obtained in step (2), the annealing temperature is 140°C, and the annealing time is 1h;

[0029] (4) The film material obtained in step (3) is subjected to polarization treatment, the polarization voltage is 20kV, the polarization distance is 15mm, the polarization temperature is 25°C, and the polarization time is 30min to obtain a charged surface with a high surface potential. bioremediation membrane mate...

Embodiment 2

[0031] (1) Weigh 2g of polymer P(VDF-TrFE), add it to 20ml organic solvent nitrogen nitrogen dimethylformamide, make the polymer solution concentration 0.1g / ml, place it on a magnetic stirrer and stir for 6h, make The polymer is uniformly dissolved and dispersed in an organic solvent to obtain a ferroelectric polymer solution;

[0032] (2) casting the mixed solution obtained in step (1) in a casting machine, and drying the film obtained by casting at a temperature of 55° C. to obtain a polymer film material with a film thickness of 70 μm;

[0033] (3) annealing the film material obtained in step (2), the annealing temperature is 40°C, and the annealing time is 1h;

[0034] (4) The thin film material obtained in step (3) is subjected to polarization treatment, the polarization voltage is 12kV, the polarization distance is 25mm, the polarization temperature is 25°C, and the polarization time is 30min, so as to obtain a charged bioremediation with a low surface potential membran...

Embodiment 3

[0036] (1) Weigh 2g of polymer P(VDF-TrFE), add it to 20ml organic solvent nitrogen nitrogen dimethylformamide, make the polymer solution concentration 0.1g / ml, place it on a magnetic stirrer and stir for 6h, make The polymer is uniformly dissolved and dispersed in an organic solvent to obtain a ferroelectric polymer solution;

[0037] (2) casting the mixed solution obtained in step (1) in a casting machine, and drying the film obtained by casting at a temperature of 55° C. to obtain a polymer film material with a film thickness of 70 μm;

[0038] (3) annealing the thin film material obtained in step (2), the annealing temperature is 90°C, and the annealing time is 1h;

[0039] (4) The thin film material obtained in step (3) is subjected to polarization treatment, the polarization voltage is 16kV, the polarization distance is 20mm, the polarization temperature is 25°C, and the polarization time is 30min, to obtain a charged bioremediation with a medium potential on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com