Multi-point direct injecting and opposite shearing and fast-mixing radial injection low-nitrogen combustor

A low-nitrogen burner and burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of large construction costs and operating costs, detonation combustion process, boiler explosion, etc., to achieve low cost, Rapid blending, reducing the effect of heat release concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

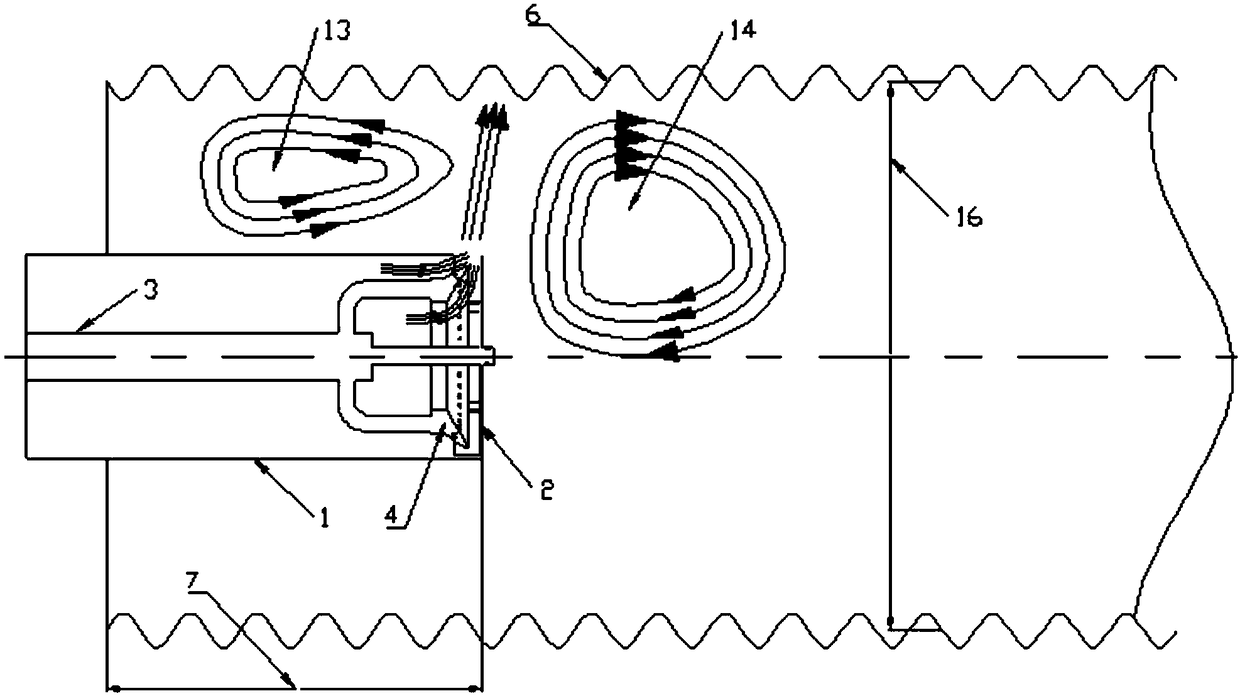

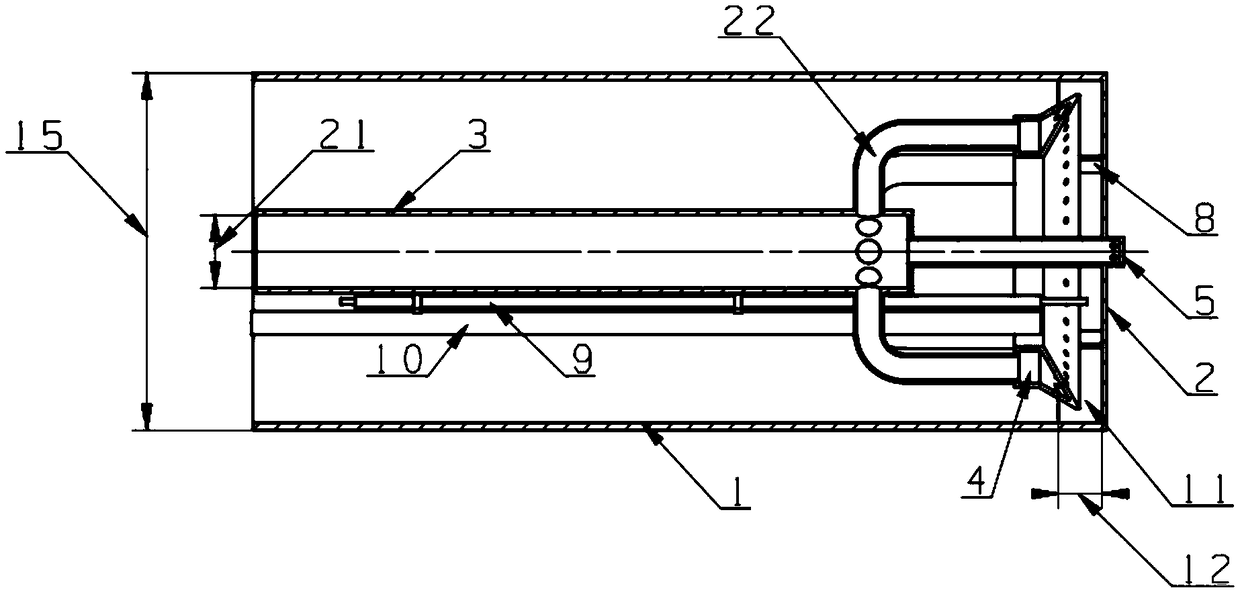

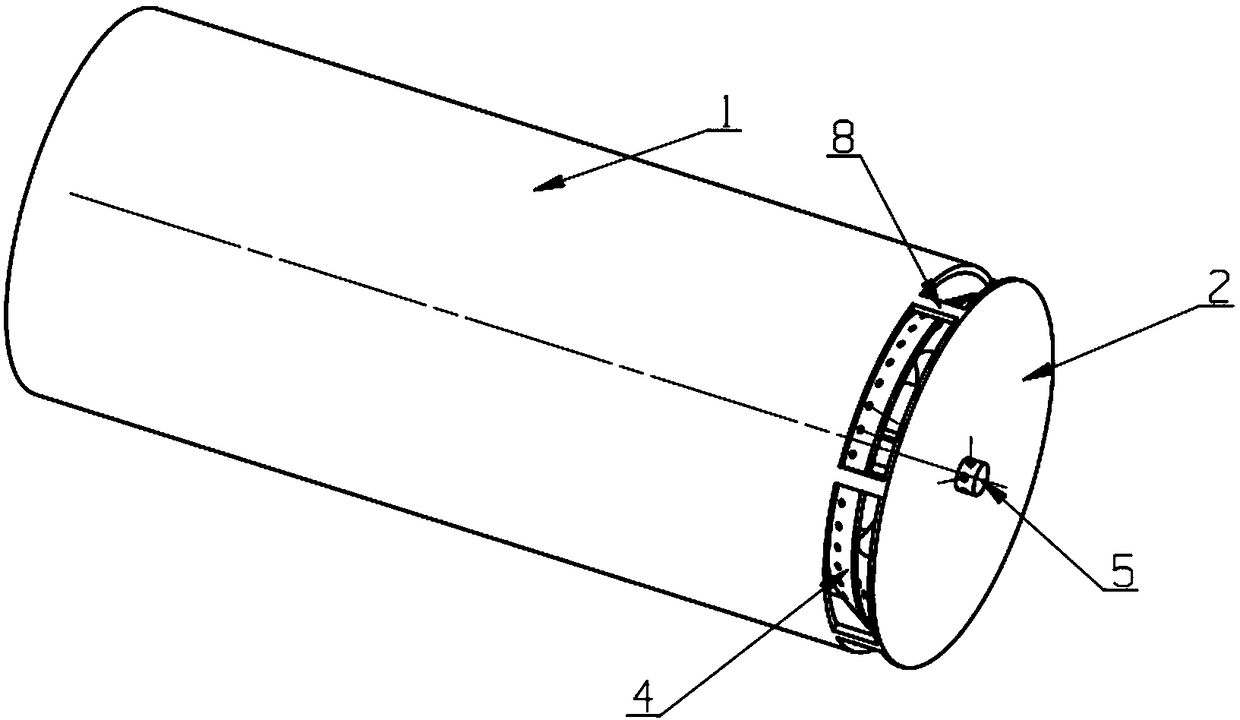

[0026] Such as figure 1 As shown, the embodiment of the present invention is mainly composed of a burner gas channel main pipe 1, a burner head baffle plate 2, a central fuel supply pipe 3, and a main road fuel injection device 4; the burner should be extended into the furnace of an industrial furnace or a gas-fired boiler 6 inside, to ensure a certain burner into the length 7;

[0027] Such as figure 2 As shown, the ignition electrode 9 is fixed on the fuel pipe 10 of the ignition path, and is inserted into the vicinity of the central fuel supply pipe 3 in the burner as a whole to ensure that the ignition electrode 9 can work; A slot 11 with a radial opening is formed between the two, and the slot width 12 and the diameter 15 of the outer ring of the main body of the burner gas passage have a certain ratio range to ensure that the gas flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com