Method of producing 5-hydroxymethyl furfural

A technology of hydroxymethyl furfural and purpose, which is applied in the field of producing 5-hydroxymethyl furfural by impacting flow coupling system, can solve the problems of dead angle and uneven mixing in the reactor, and achieve the effect of reducing energy consumption and being beneficial to the hydrolysis reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

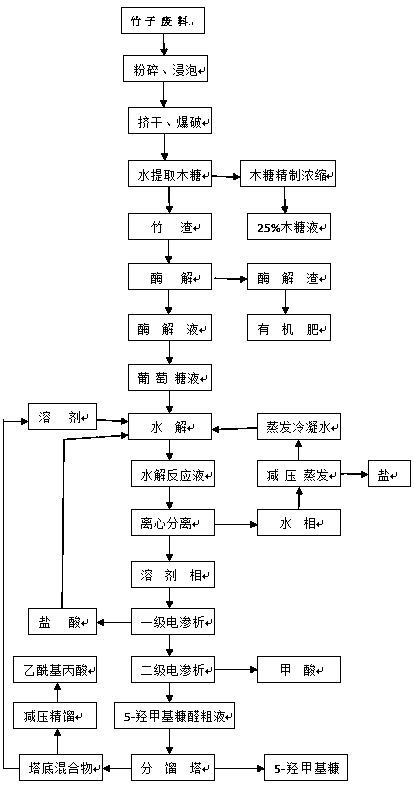

Image

Examples

Embodiment 1

[0068] Bamboo leftovers (including bamboo shreds, bamboo sawdust, and bamboo processing waste) are crushed to small particles of 25 mesh; 0.5% dilute sulfuric acid is added to 10 times the amount of dry matter, soaked for 10 hours, and squeezed dry; the squeezed bamboo particles are used Steam explosion method is carried out blasting treatment to the bamboo as raw material, obtains the bamboo material after steam explosion treatment; Bamboo particle blasting adopts instant blaster, blasting temperature 190 ℃ holding time 80s, blasting time 0.00087s; Most of the hemicellulose is degraded to Xylose: the bamboo material after the steam explosion treatment is carried out continuous water extraction, wherein the xylose is extracted with water, the water extract is filtered, the ultrafiltration membrane is used to remove impurities, and the nanofiltration membrane is concentrated to a xylose content of 15% (mass percentage) ; Squeeze dry at the same time to obtain bamboo residue with...

Embodiment 2

[0071] 5-hydroxymethylfurfural is prepared according to a conventional solvent extraction method, and then the yields of hydrochloric acid and formic acid are compared with those of the present invention.

Embodiment 3

[0073] The preparation of 5-hydroxymethylfurfural was carried out according to the method and steps of Example 1, except that the hydrolysis temperature was changed to 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com