A kind of biotype thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and bio-based technology, applied in the field of polyurethane materials, can solve the problems of polyurethane performance improvement without further research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

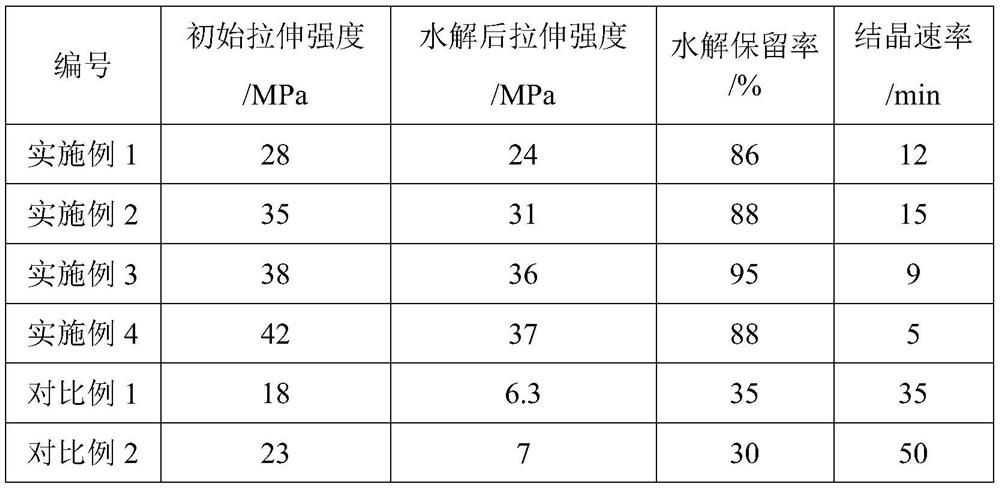

Examples

preparation example Construction

[0034]Preparation of bio-based thermoplastic polyurethane elastomer

[0035] The bio-based raw material information involved in the embodiments of the present invention is as follows:

[0036] Bio-based polyester polyols:

[0037] Bio-based succinic acid, purchased from BioAmber company;

[0038] Bio-based sebacic acid was purchased from Hebei Kaide Biomaterials Co., Ltd.;

[0039] Bio-based 1,3-propanediol was purchased from DuPont.

[0040] Preparation of bio-based poly(1,3-propylene glycol succinate):

[0041] Add bio-based succinic acid and bio-based 1,3-propanediol in a molar ratio of 1:1.2 into a reaction kettle with a fractionation tower and a distillation receiver, and heat up to 180°C for reaction. When the acid value drops to 15mg KOH / g , evacuate to below 100pa, raise the temperature to 200°C to continue the reaction, stop the reaction when the acid value is less than 1.5mg KOH / g, and the hydroxyl value reaches the predetermined value. A hydroxyl value of 56 mg...

Embodiment 1

[0055] 67 wt% PPSu (bio-based polypropylene succinate), 16.7 wt% MDI (4,4-diphenylmethane diisocyanate), 7 wt% BDI (bio-based 1, 4-butylene diisocyanate), 9.29wt% PDO (bio-based 1,3-propanediol), 0.01wt% bismuth isooctanoate were mixed evenly, and then extruded through twin-screw reaction (extruder temperature 160 ° C) to obtain bio-based thermoplastic polyurethane elastomer.

Embodiment 2

[0057] 41.5 wt% PPSu (bio-based polypropylene succinate) with a molecular weight of 1000 g / mol, 25.48 wt% MDI (4,4-diphenylmethane diisocyanate), 14.01 wt% BDI (bio-based 1,4-butylene diisocyanate), 19wt% PDO (bio-based 1,3-propanediol), 0.01wt% bismuth isooctanoate, mixed evenly, and then extruded through twin-screw reaction (extruder temperature 180°C) to obtain bio-based Thermoplastic polyurethane elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com