High-yield preparation method of high-purity dimethyl diallyl ammonium chloride monomer

A dimethyl diallyl ammonium chloride, high-yield technology, applied in the field of high-yield preparation of high-purity dimethyl diallyl ammonium chloride monomer, can solve the problem of low reaction yield and process Complicated, many process steps, etc., to achieve the effect of high purity, less impurities, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

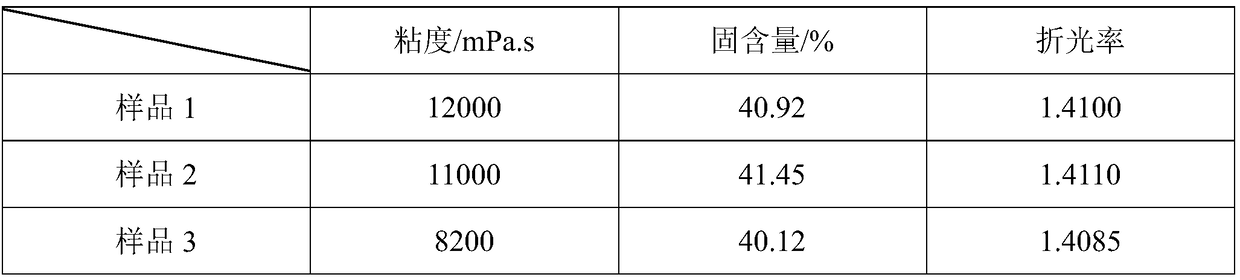

Embodiment 1

[0061] A kind of preparation method of high-purity DMDAAC monomer high yield, its step is:

[0062] Tertiary amination reaction stage: pump 141kg of 40% dimethylamine aqueous solution into a sealed and pressure-resistant reactor equipped with speed-adjustable agitator, pressure gauge, online pH meter, cooling water pipe, heating water pipe, feeding pump, and vacuum pump , circulating water to maintain the temperature in the reactor at 25°C. The reaction kettle was sealed, and the pressure in the kettle was observed with a pressure gauge, and the reaction in the tertiary amination stage was started, and the temperature was controlled at 30°C. Described feeding pump, wherein chloropropene uses a pump, dimethylamine aqueous solution and sodium hydroxide aqueous solution can use a pump

[0063] Step (1): Add 60kg of allyl chloride dropwise into the reactor, and finish adding one-third of the amount of allyl chloride dropwise within 10min-20min, control the pressure in the kettle ...

Embodiment 2

[0073] A kind of preparation method of high-purity DMDAAC monomer high yield, its step is:

[0074]Tertiary amination reaction stage: pump 141kg of 40% dimethylamine aqueous solution into a sealed and pressure-resistant reactor equipped with speed-adjustable agitator, pressure gauge, online pH meter, cooling water pipe, heating water pipe, feeding pump, and vacuum pump , circulating water to maintain the temperature in the reactor at 25°C. The reaction kettle was sealed, and the pressure in the kettle was observed with a pressure gauge, and the reaction in the tertiary amination stage was started, and the temperature was controlled at 40°C. Described feeding pump, wherein chloropropene uses a pump, dimethylamine aqueous solution and sodium hydroxide aqueous solution can use a pump

[0075] Step (1): Add 65kg of allyl chloride dropwise into the reaction kettle, and finish adding one-third of the amount of allyl chloride dropwise in 10min-20min. Under reaction 1h.

[0076] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com