Explosive welding method for manufacturing composite plate from C-276 alloy

A C-276, explosive welding technology, used in the field of composite panels, can solve the problems of non-fitting, the jet material cannot be completely eliminated, and the bonding strength of both ends is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims:

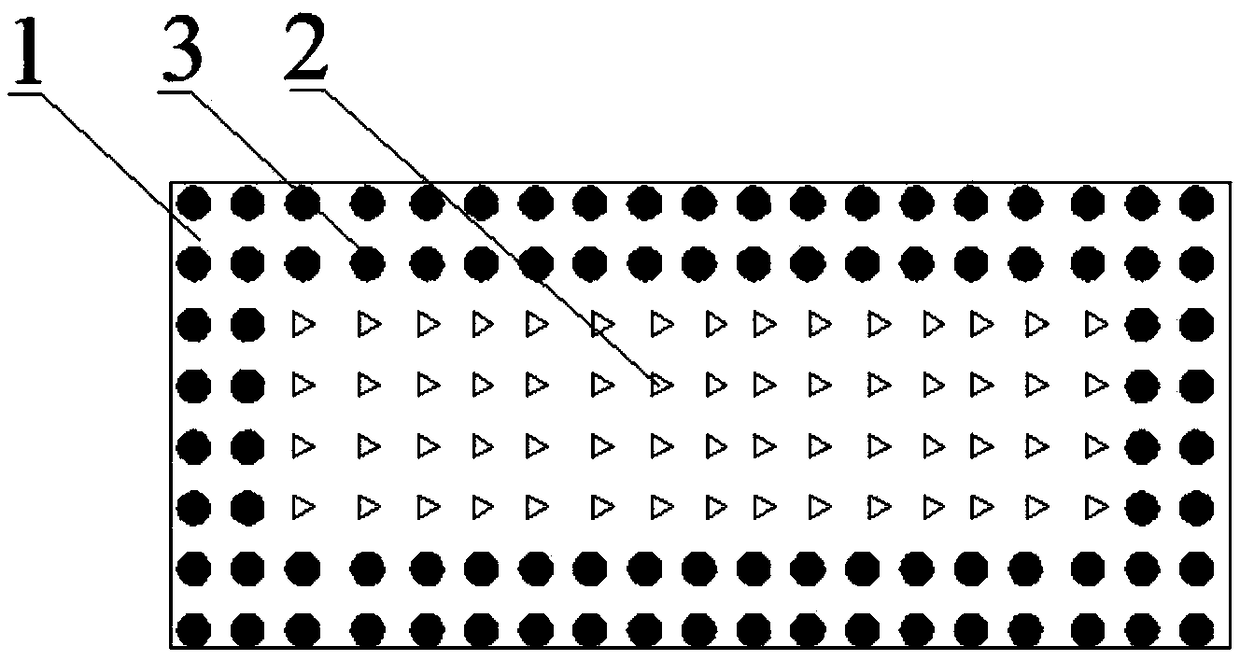

[0021] The present invention provides a kind of explosive welding method that utilizes C-276 alloy to make composite plate, comprises steel plate 1, C-276 alloy plate, and the method for the explosive welding forming of composite plate is as follows:

[0022] Step 1: Get ready to grind once before the explosion. Treated steel plate 1. C-276 alloy plate. The thickness of the selected C-276 alloy plate is 3mm, and the plate size is 9550mm×3250mm (L×W); steel plate 1 is made of Q345 Made of steel, the thickness of the steel plate 1 is 50mm, and the size of the plate is 9500mm×3250mm (L×W), so as to make a composite plate with an area greater than 25m2;

[0023] Step 2: Select several conventional support blocks 2 that meet the requirements and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com