[0002] As we all know, with the advancement of technology and the increase of labor costs, the sheet

metal industry has more and more urgent requirements for intelligent and unmanned equipment. Among them, the CNC turret

punch press is a major

processing equipment in the sheet metal industry. It consists of

Computer control, widely used in electrical switches,

electronics,

instrumentation, computers,

textile machinery, office machinery and other industries, CNC turret punch is the fastest growing product in CNC

forging machinery, the market has a large amount, but CNC turret punch is common There is a problem that the degree of intelligence is not high, especially the loading and unloading of the CNC

brick tower punching machine still requires manual loading and unloading, which is especially not suitable for

mass production and

processing of products. During the normal operation of the

tower punch press, the intelligent loading and unloading device for the CNC

brick tower

punch press has been widely used in the field of numerical

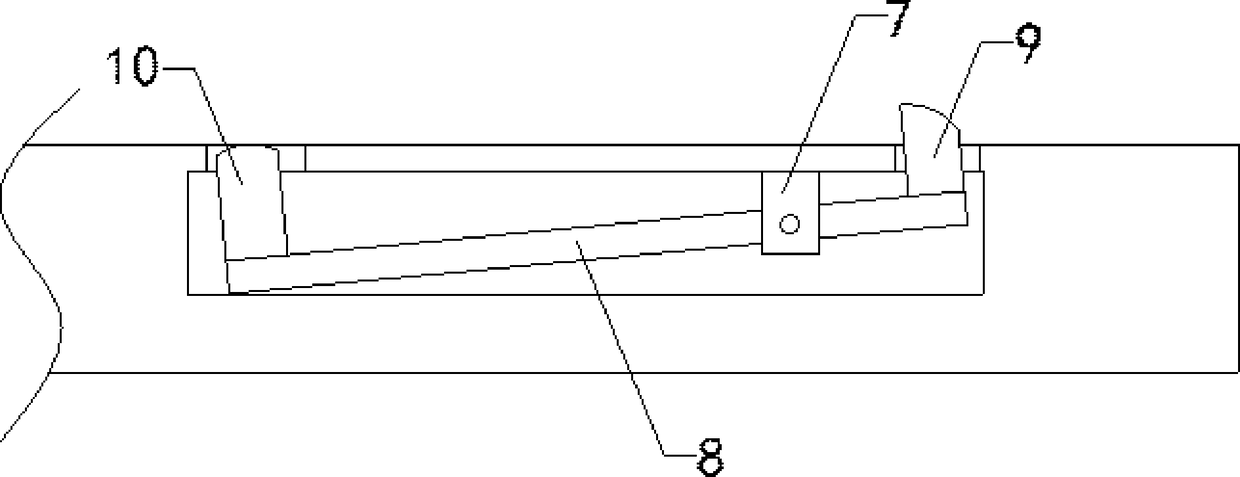

control equipment; the existing compact intelligent loading and unloading equipment for the CNC turret punch press includes a mounting frame , palletizing platform, mobile platform, feeding device, lifting and reclaiming device and central control module, the front and rear sides of the top of the mounting frame are respectively provided with two sets of upper fixing frames, and the left sides of the lower ends of the two groups of upper fixing frames There are four sets of outriggers on the right side and the front side of the bottom of the two sets of mounting frames respectively. The top left side of the top of the two sets of upper fixing frames are respectively provided with two sets of slide rails, the front side and the rear side of the lower end of the mobile platform are respectively slid and clamped with the two sets of slide rails, and the middle part of the bottom end of the mobile platform is provided with a power device, the

power unit is electrically connected to the central control module, two sets of supporting frames are respectively provided at the front end and the rear end of the feeding device, clamps are provided at the bottom area of the feeding device, a lifter is provided at the bottom of the feeding device, and two sets of supporting frames The bottom ends of the two sets of upper fixed frames are respectively connected to the front and rear middle areas of the top. A drive module is arranged inside the feeding device. The drive module is electrically connected to the central control module. The front and rear ends of the lifting and reclaiming device are respectively There are two sets of lifting devices. The bottom of the lifting and reclaiming device is equipped with an intelligent reclaiming module. The lifting device of the elevating and reclaiming device is equipped with a driver. Both the driver and the intelligent reclaiming module are electrically connected to the central control module. The central control module The front side and the back side of the left end are respectively connected with the right ends of the two sets of legs on the right side; when the existing CNC turret punch press compact intelligent loading and unloading equipment is used, the working program is first set through the central control module, and then the lifting and reclaiming device It comes with intelligent picking modules such as plate thickness layering, magnetic layering, double-material detection and vacuum suction, etc., and absorbs a single sheet through layering and double-material detection, and each time the material is a single sheet, and then The lifting and reclaiming device absorbs the

sheet material at a predetermined position, and then the moving table moves to the bottom of the sucked

sheet material, and then the lifting and reclaiming device automatically places the sheet on the moving table and then moves to the initial position, and the lifting and reclaiming device waits for the moving table to move to the original position. After the front movement resets, the next plate is taken, and then the mobile table moves forward to the bottom of the feeding device, and then the mobile table waits for the clamp on the feeding device to clamp the plate, and at the same time, the lifting and reclaiming device takes out the next plate. It moves to the bottom of the plate sucked by the lifting and reclaiming device, and then the upper clamp of the feeding device clamps the plate and transports it to the position of the CNC punching origin. The feeding device completes the positioning and clamping of the plate and the punching machine, and then the feeding device withdraws In the waiting area, when the feeding device waits for the CNC punching machine to complete the plate processing, it moves forward again to pick up the plate and then retracts to the table above the palletizing device. At this time, the mobile table has moved to the bottom of the lifting and reclaiming device, and it is out of the way. The position on the upper side of the palletizing device. At this time, the feeding device descends through its lifter and releases the clamps, thus completing the blanking and palletizing of the finished material on the palletizing table, and then repeating the above process to realize loading and unloading. It is found in the use of the existing compact intelligent loading and unloading equipment for CNC turret punch presses that, first of all, when the feeding device clamps the sheet through the clamp, because the sheet is close to the moving table, the feeding device passes through the clamp. It is more difficult for the clamp to pick up the sheet, which leads to poor practicability; and when the feeding device puts the processed sheet on the palletizing table, since the feeding device has no limiting device, the sheet is placed on the palletizing table. It is prone to skewing on the surface, which easily causes the sheet to slip and brings inconvenience to the transportation of the sheet, resulting in high use limitations

Login to View More

Login to View More  Login to View More

Login to View More