Controllable heating vacuum pressure filtration solid-liquid separation device

A technology of solid-liquid separation and vacuum pressure, which is applied in the field of chemical analysis experimental equipment, can solve the problems of poor efficiency during press filtration, inability to heat materials, difficulty in replacing filter screens, etc., achieve shortened time, excellent separation effect, and increase separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

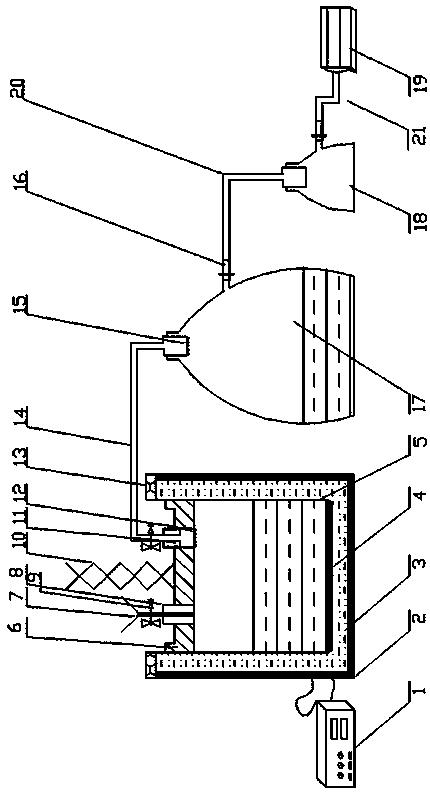

[0028] Embodiment 1: as figure 1 As shown, a controllable heating vacuum filter press solid-liquid separation device includes a temperature controller 1, a heat insulation box 2, and a filter press box 5. Several heating jackets are uniformly arranged on the inner wall of the heat insulation box 2, and the temperature controller 1. The electric wire is connected to the heating jacket electrically, and the heating jacket is provided with an electric heating pipe, and the electric heating pipe is filled with heat transfer oil 3. The heating jacket forms a heating chamber, and the filter press box 5 is vertically placed in the heating chamber. , the bottom surface of the filter press box 5 is a heat transfer plate 4, the bottom of the heat transfer plate 4 is provided with a temperature sensor, the temperature sensor is connected with the temperature controller 1 through a data transmission line, the top plate 6 of the filter press box 5 is provided and the edge of the top plate 6...

Embodiment 2

[0030] Embodiment 2: A controllable heating type vacuum filter press solid-liquid separation device, including a temperature controller 1, an adiabatic box 2, and a filter press box 5. Several heating jackets are evenly arranged on the inner wall of the adiabatic box 2, and the temperature control The device 1 is electrically connected to the heating jacket through electric wires, and the heating jacket is provided with an electric heating pipe, and the electric heating pipe is filled with heat transfer oil 3, and the heating jacket forms a heating chamber, and the filter press box 5 is vertically placed in the heating chamber Inside the body, the bottom surface of the filter press box 5 is a heat transfer plate 4, the bottom of the heat transfer plate 4 is provided with a temperature sensor, the temperature sensor is connected to the temperature controller 1 through a data transmission line, the top of the filter press box 5 is provided with a top plate 6 and the top plate 6 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com