Heat exchanger

A technology of heat exchangers and heat exchange tubes, which is applied to heat exchange equipment, heat exchanger types, heat exchanger shells, etc., and can solve problems such as insufficient corrosion resistance of heat exchange tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

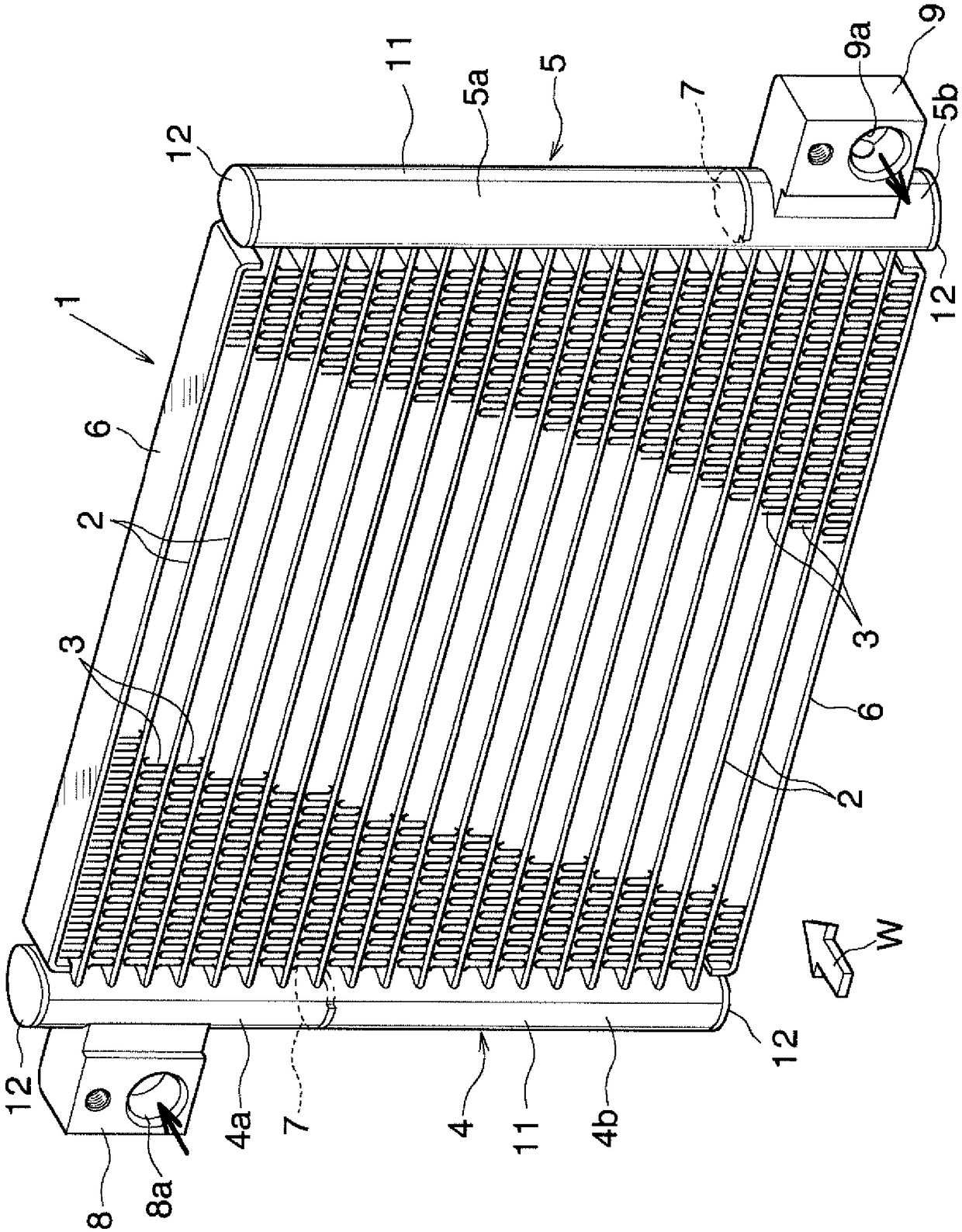

[0014] Embodiments of the present invention will be described below with reference to the drawings. In this embodiment, the heat exchanger of the present invention is applied to a condenser for an automobile air conditioner.

[0015] figure 1 It shows the overall structure of the condenser for automobile air conditioner to which the heat exchanger of the present invention is applied, figure 2 Indicates the structure of its main part.

[0016] And, in the description below, the figure 1 Up and down, left and right are called up and down, left and right.

[0017] exist figure 1 Among them, a condenser 1 for an automobile air conditioner includes: a plurality of flat heat exchange tubes 2 made of aluminum extruded materials, which have their longitudinal directions oriented to the left and right directions and their width directions oriented to the ventilation direction. The thickness direction of the tube 2) is arranged at intervals; the corrugated fins 3 made of aluminum-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com