Solvent-free adhesive composition, adhesive sheet and display body

A display body and adhesive technology, applied in the direction of adhesive types, adhesives, adhesive additives, etc., can solve the problems of light reflection loss, etc., and achieve excellent step followability and excellent anti-foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] 2. Preparation of solvent-free adhesive composition

[0089] The solvent-free adhesive composition P can be prepared by mixing the active energy ray-curable components (A) and the photopolymerization initiator (B), and adding a silane coupling agent (C) as necessary. ) and additives.

[0090] Moreover, since the solventless adhesive composition P which concerns on this embodiment is a solventless type, it has suitable viscosity mainly by a polymerization component. Therefore, the non-solvent adhesive composition P according to this embodiment can be used as a coating solution without adding a diluent or the like.

[0091] [adhesive sheet]

[0092] The adhesive sheet according to the present embodiment includes an adhesive layer for adhering one display constituent member and the other display constituent member.

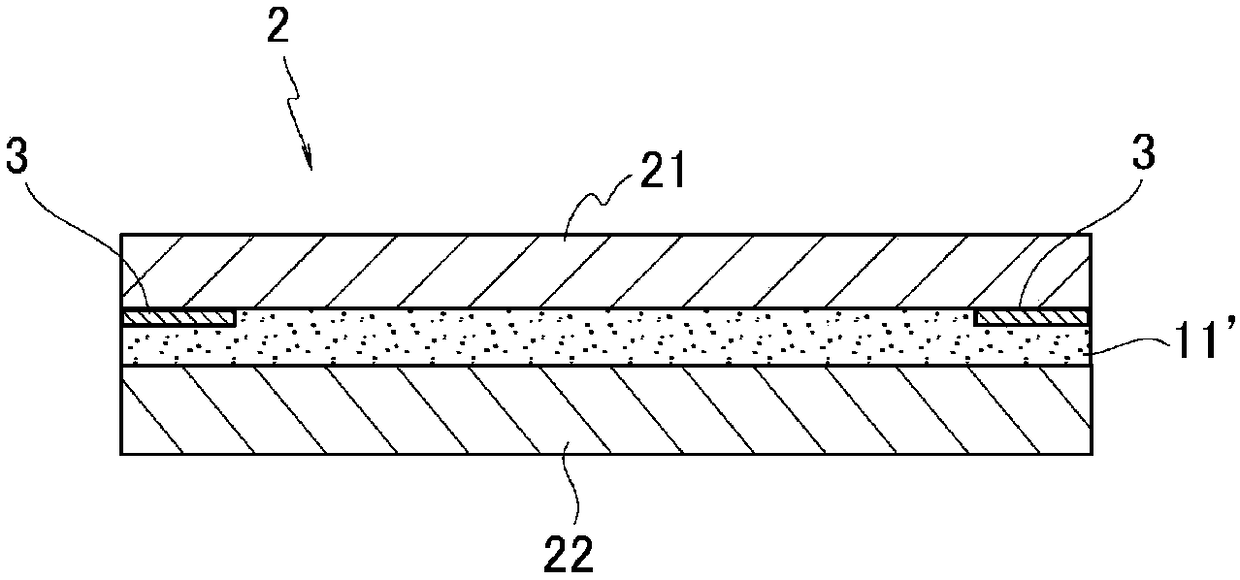

[0093] Such as figure 1 As shown, the adhesive sheet 1 according to the present embodiment as an example consists of two release sheets 12a, 12b, and is c...

Embodiment 1

[0159] 1. Preparation of Urethane Acrylate Oligomers

[0160] 1 mole of polypropylene glycol (PPG) with a weight average molecular weight of 9,200, 2 moles of isophorone diisocyanate (IPDI), and 2 moles of 2-hydroxyethyl acrylate (HEA) were polymerized to obtain urethane acrylate Oligomer-like polyether urethane acrylate with a weight average molecular weight of 9,900.

[0161] In addition, the weight average molecular weight of polypropylene glycol and polyether urethane acrylate is the standard polystyrene conversion value measured on the following conditions by gel permeation chromatography (GPC).

[0162] ・GPC measurement device: manufactured by TOSOH CORPORATION, HLC-8020

[0163] ・GPC column: Manufactured by TOSOH CORPORATION (below, listed in order of passage)

[0164] TSK guard Column HXL-H

[0165] TSK gel GMHXL (×2)

[0166] TSK gel G2000HXL

[0167] ·Measurement solvent: tetrahydrofuran

[0168] ·Measurement temperature: 40℃

[0169] 2. Preparation of solvent...

Embodiment 2

[0183] In the same manner as in Example 1, except that the type and blending amount of the photopolymerization initiator (B) were changed to 1.5 parts by mass of 2,4,6-trimethylbenzoyl-diphenyl-phosphine oxide An adhesive sheet and an adhesive sheet with a covering material were produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com