A kind of Rosa roxburghii polysaccharide and its preparation method and application

A technology of prickly pear and polysaccharide is applied in the field of health food to achieve the effects of high purity, inhibitory activity and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation method of Rosa roxburghii polysaccharide, comprising the following steps:

[0056] (1) Raw material pretreatment: wash the fresh Rosa roxburghii fruit and put it in a tray, and dry it in a blast drying oven at 60°C for 48 hours. Crush, pass through a 40-mesh sieve, formulate a solid-to-liquid ratio of 1:6g / mL according to Rosa roxburghii dry powder and 95% ethanol (v / v), heat to reflux in a water bath at 70°C for 4 hours, filter to obtain the residue, heat to reflux and filter Repeat 4 times, put the degreased Rosa roxburghii dry powder into a blast drying oven at 45°C for 48 hours.

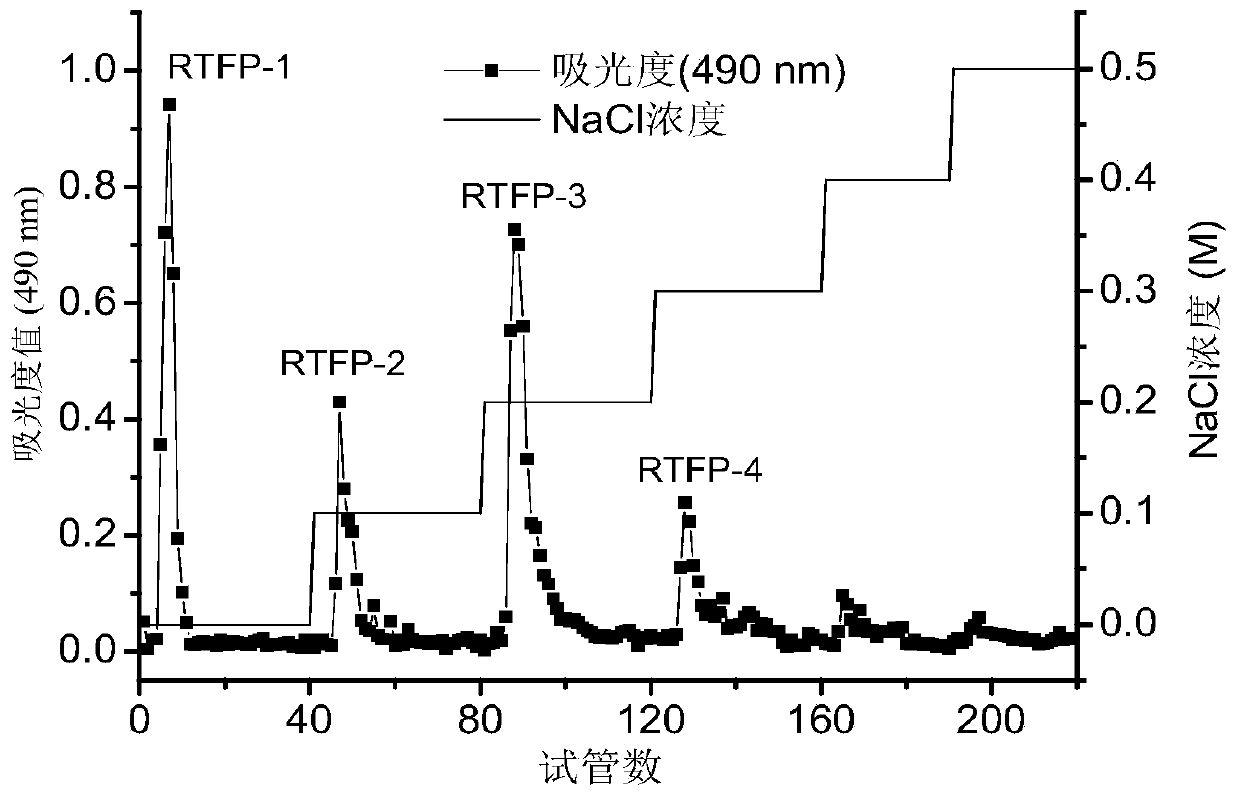

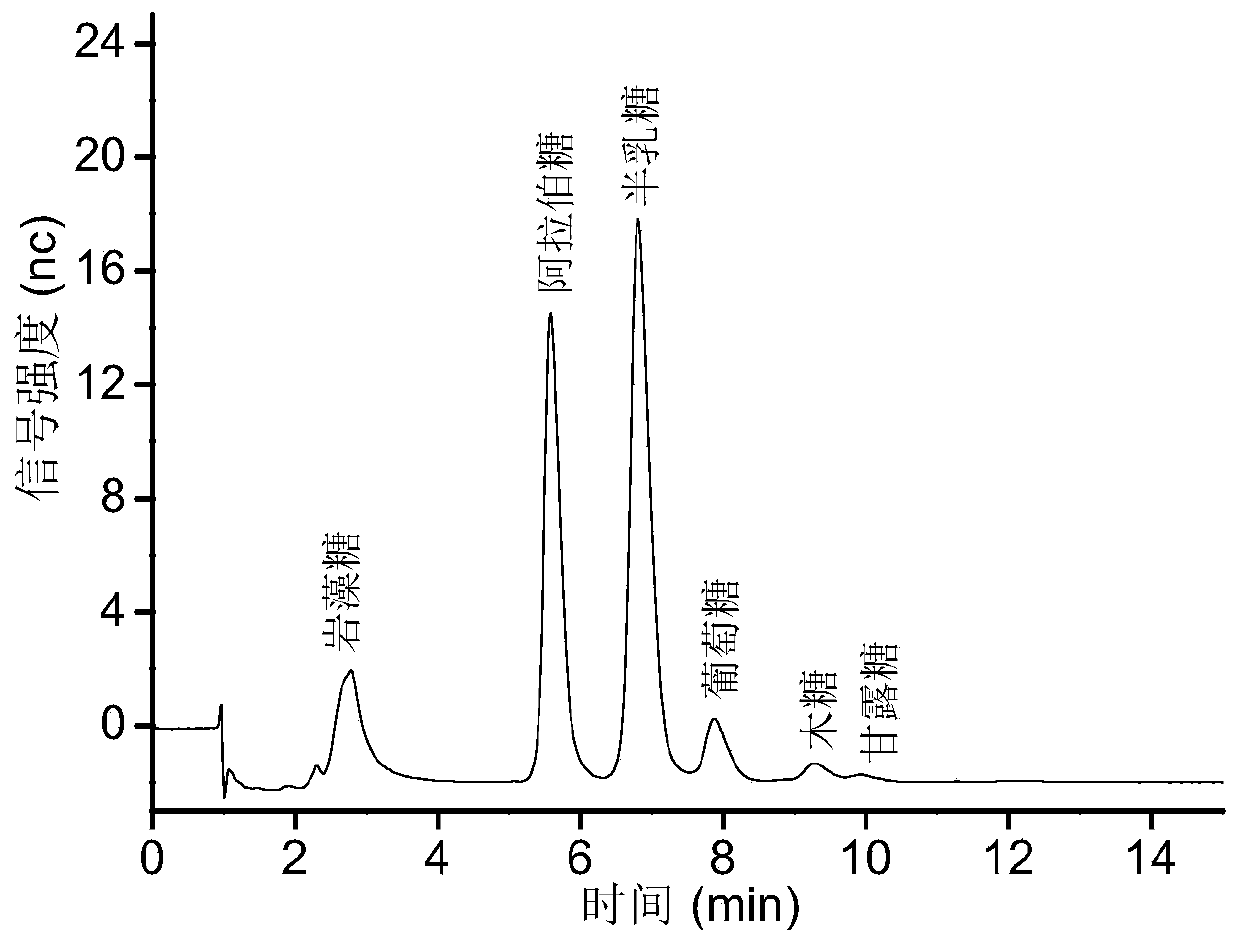

[0057] (2) Add 150 g of the treated Rosa roxburghii powder into distilled water for hot water leaching, the leaching temperature is 95° C., the time is 3 hours, and the ratio of solid to liquid is 1:30 (the units of mass and volume are g and mL, respectively). The number of times is 2 times; the centrifugal force is 5000g, centrifuged for 10min, and the supernatant is collec...

Embodiment 2

[0064] A preparation method of Rosa roxburghii polysaccharide, comprising the following steps:

[0065] (1) Raw material pretreatment: wash the fresh Rosa roxburghii fruit and put it in a tray, and dry it in a blast drying oven at 60°C for 48 hours. Grind, pass through a 50-mesh sieve, formulate a solid-to-liquid ratio of 1:5g / mL according to Rosa roxburghii dry powder and 95% ethanol (v / v), heat to reflux in a water bath at 75°C for 3 hours, filter to obtain the residue, heat to reflux and filter Repeat 3 times, put the degreased Rosa roxburghii dry powder into a blast drying oven at 55°C and dry for 36 hours.

[0066] (2) Get 150g of Rosa roxburghii dry powder treated in (1), add distilled water and carry out hot water extraction, extraction temperature 95 ℃, time 2h, solid-liquid ratio 1:20, extraction times is 3 times; Centrifugal force 8000g, After centrifugation for 5 min, the collected supernatant was concentrated to 1 / 3 of the original volume by rotary evaporation at ...

Embodiment 3

[0072] A preparation method of Rosa roxburghii polysaccharide, comprising the following steps:

[0073] (1) Raw material pretreatment: wash the fresh Rosa roxburghii fruit and put it in a tray, and dry it in a blast drying oven at 60°C for 48 hours. Grind, pass through a 60-mesh sieve, formulate a solid-to-liquid ratio of 1:4g / mL according to Rosa roxburghii dry powder and 95% ethanol (v / v), heat to reflux in a water bath at 80°C for 2 hours, filter to obtain the residue, heat to reflux and filter Repeat 2 times, put the degreased Rosa roxburghii dry powder into a blast drying oven at 65°C for 24 hours.

[0074] (2) Take 150g of Rosa roxburghii dry powder treated in (1), add distilled water for hot water extraction, extraction temperature is 95°C, time is 3.5h, solid-liquid ratio is 1:35, extraction times is 1 time; centrifugal force is 4000g , centrifuged for 15 min, and the supernatant was collected and concentrated to 1 / 5 of the original volume by rotary evaporation at 65°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com