Geological polymer porous heat-insulation material based on municipal solid waste incineration bottom ash and preparation method of geological polymer porous heat-insulation material

A technology of municipal solid waste and geopolymer, applied in the field of building materials, can solve the problems of large consumption of natural mineral materials, high price, resource depletion, etc., and achieve the effects of good stability, good compressive strength and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

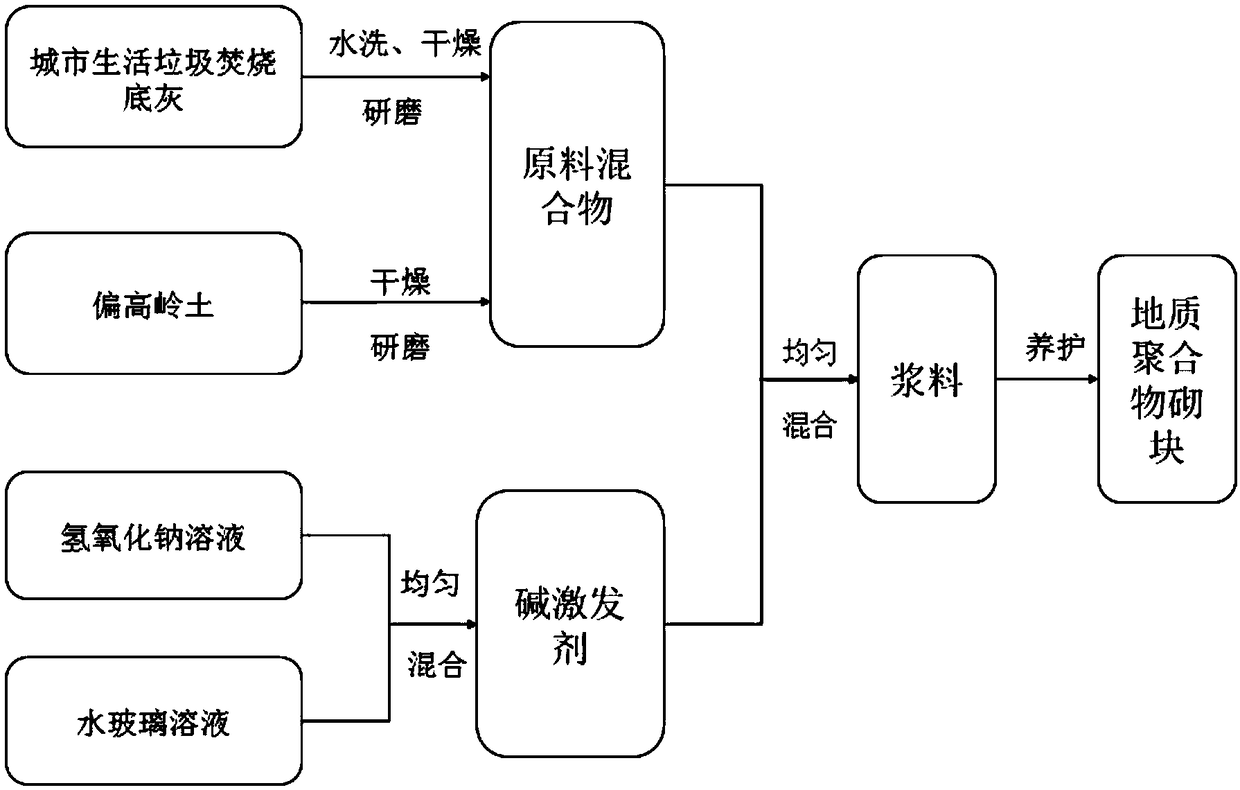

Image

Examples

Embodiment 1

[0025] A geopolymer based on municipal solid waste incineration bottom ash, its basic composition includes the following components by mass percentage: incineration bottom ash 75%, metakaolin 25%.

[0026] Preparation method: first wash the incineration bottom ash with water, then dry the incineration bottom ash and metakaolin separately, and ball mill, then grind the incineration bottom ash and metakaolin into powders smaller than 75 μm, and mix uniformly according to the proportion to obtain a raw material mixture. Sodium hydroxide solution (8mol / L) and water glass solution are mixed at a mass ratio of 1:3 to obtain an alkali activator. An alkali activator (the amount of the alkali activator is 25% of the mass of the mixture) is added to the raw material mixture and stirred uniformly for 30 minutes to obtain geopolymer slurry. The slurry was poured into a mold (40mm×40mm×160mm), dried in a drying oven at 70°C for 24 hours, and then demolded, and then cured under moist heat a...

Embodiment 2

[0028] A geopolymer based on municipal solid waste incineration bottom ash, its basic composition includes the following components by mass percentage: incineration bottom ash 72%, metakaolin 28%.

[0029] Preparation method: first wash the incineration bottom ash with water, then dry the incineration bottom ash and metakaolin separately, and ball mill, then grind the incineration bottom ash and metakaolin into powders smaller than 75 μm, and mix uniformly according to the proportion to obtain a raw material mixture. Sodium hydroxide solution (8mol / L) and water glass solution are mixed at a mass ratio of 1:3 to obtain an alkali activator. An alkali activator (the amount of the alkali activator is 28% of the mass of the mixture) was added into the raw material mixture and stirred uniformly for 45 minutes to obtain geopolymer slurry. The slurry was poured into a mold (40mm×40mm×160mm), dried in a drying oven at 70°C for 24 hours, and then demolded, and then cured under moist hea...

Embodiment 3

[0031] A geopolymer based on municipal solid waste incineration bottom ash, its basic composition includes the following components by mass percentage: incineration bottom ash 68%, metakaolin 32%.

[0032] Preparation method: first wash the incineration bottom ash with water, then dry the incineration bottom ash and metakaolin separately, and ball mill, then grind the incineration bottom ash and metakaolin into powders smaller than 75 μm, and mix uniformly according to the proportion to obtain a raw material mixture. Mix sodium hydroxide solution (8mol / L) and water glass solution in a mass ratio of 1:4 to obtain an alkali activator. An alkali activator (the amount of the alkali activator is 30% of the mass of the mixture) is added to the raw material mixture and stirred uniformly for 60 minutes to obtain geopolymer slurry. The slurry was poured into a mold (40mm×40mm×160mm), dried in a drying oven at 70°C for 24 hours, and then demolded, and then cured under moist heat at 80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com