A membrane wall reactor for continuous thermal hydrolysis of sludge for supercritical water oxidation system

An oxidation system, supercritical water technology, applied in the oxidation treatment of sludge, water/sludge/sewage treatment, sludge treatment, etc. Condition and other problems, to achieve the effect of preventing heat transfer deterioration, improving heat transfer efficiency, and efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

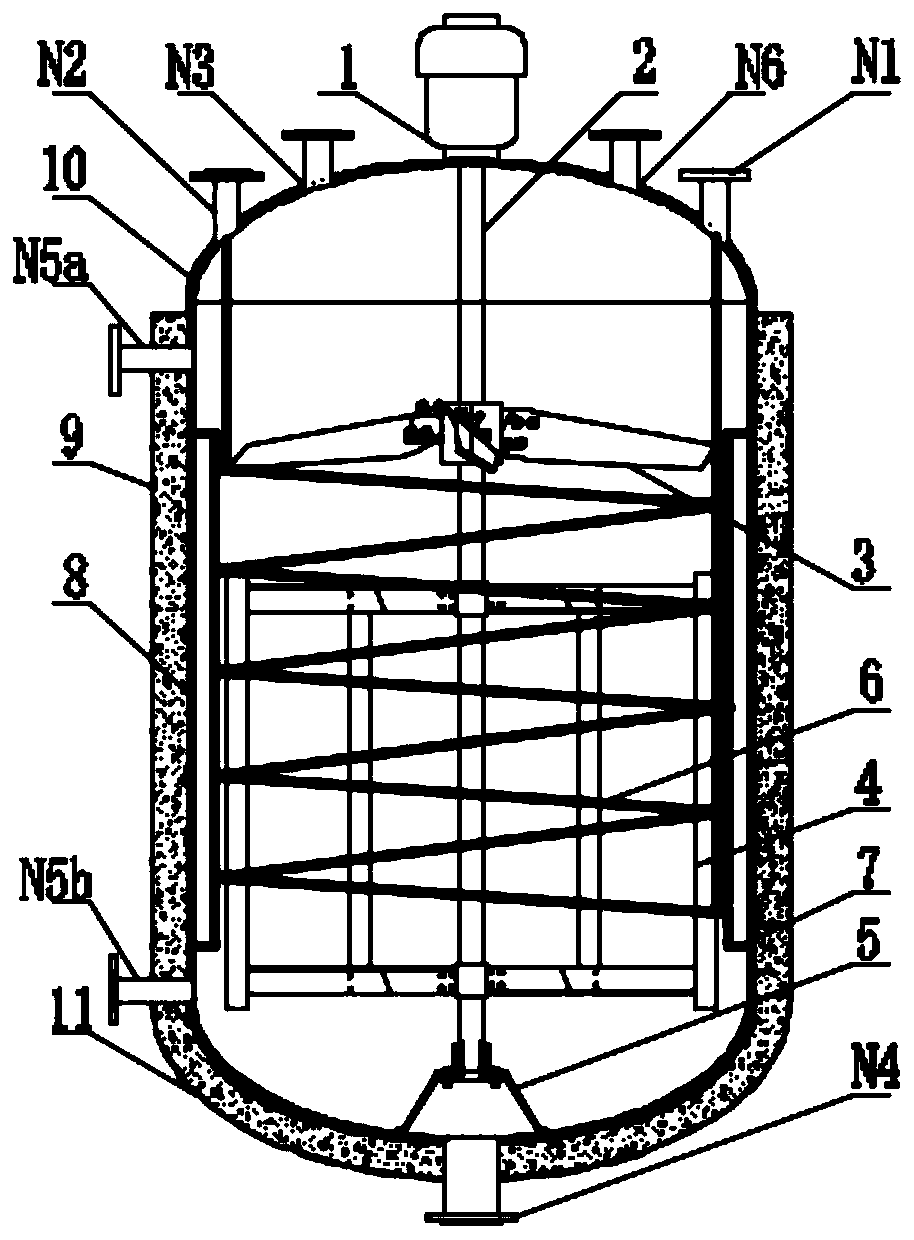

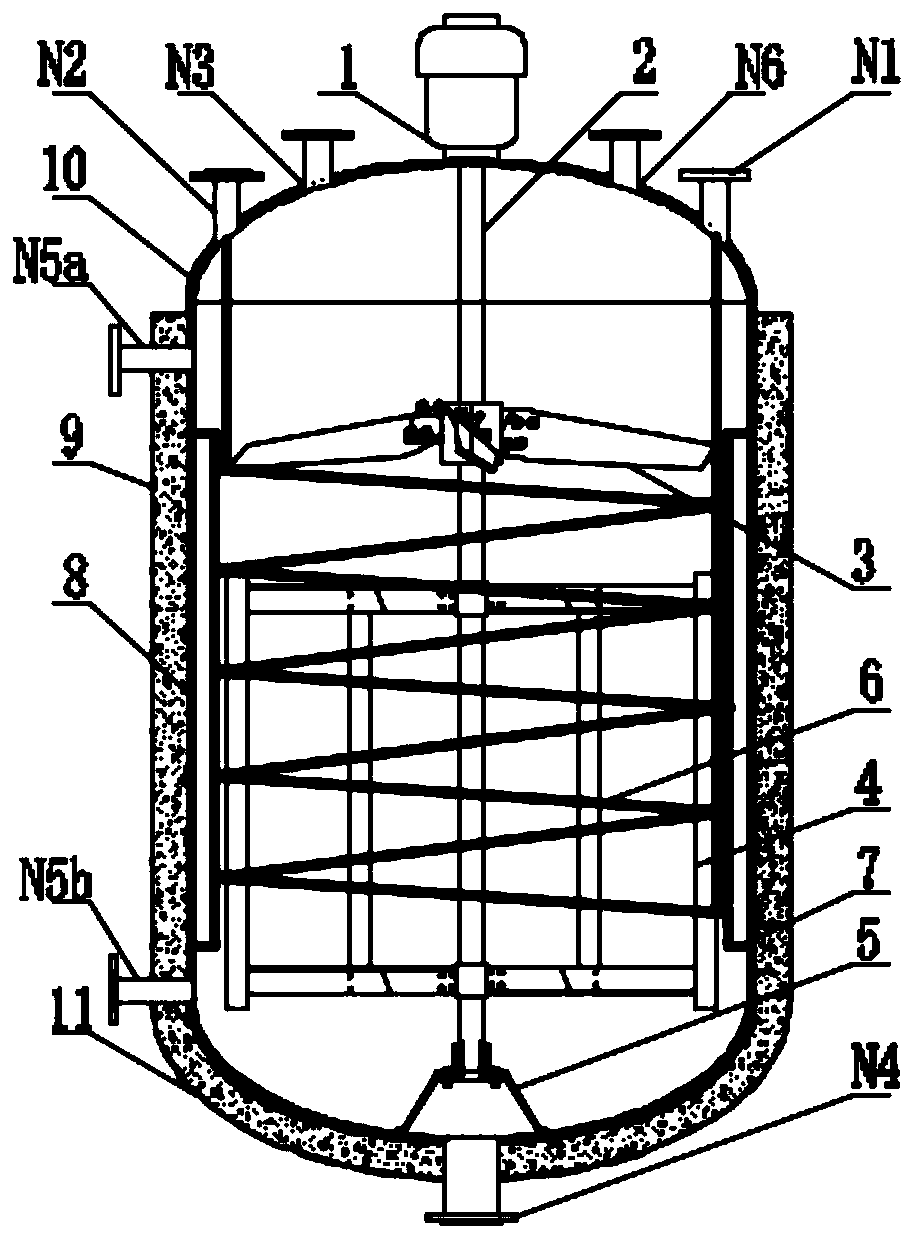

[0033] refer to figure 1 As shown, the sludge continuous thermal hydrolysis membrane wall reactor for supercritical water oxidation system of the present invention includes a cylinder 8, a membrane wall heat exchanger 6 and a stirring device; the top of the cylinder 8 is provided with an upper A head 10, a lower head 11 is provided at the bottom, and an insulation layer 9 is provided outside the cylinder body 8 and the lower head 11;

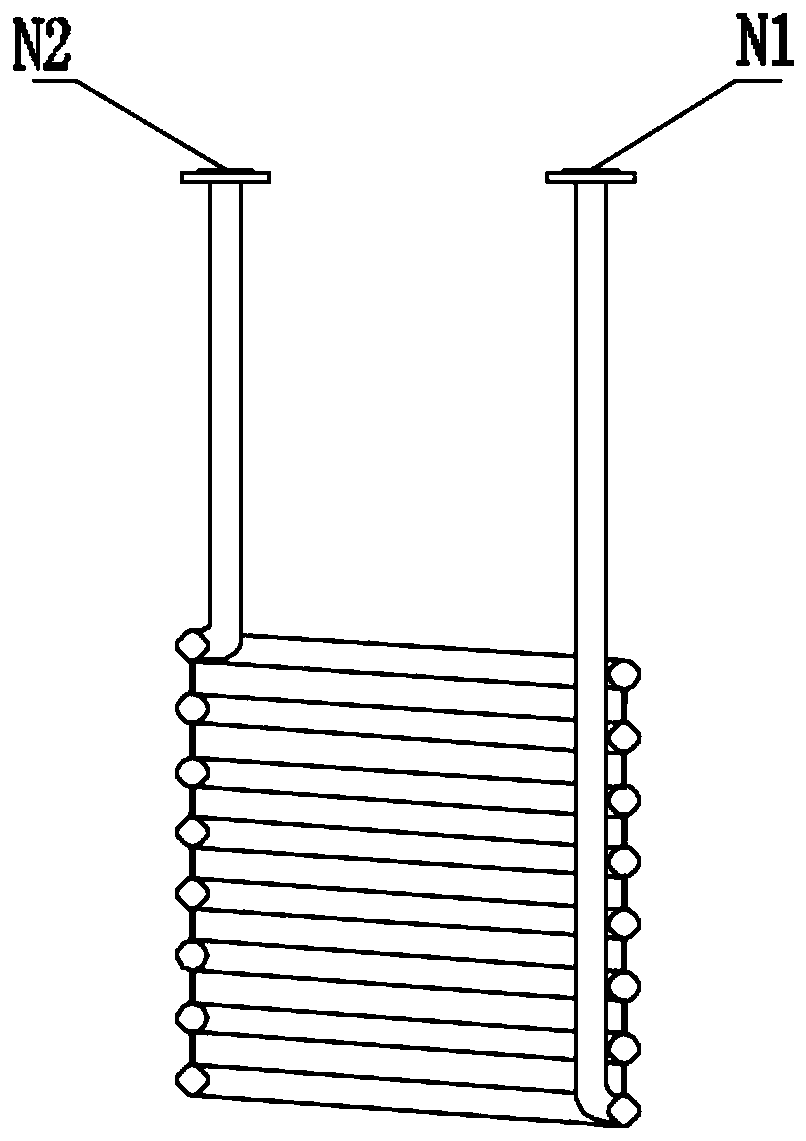

[0034] The cylinder 8 is also provided with a membrane wall heat exchanger 6 coaxial with the cylinder 8 and close to the side wall of the cylinder 8. The structure of the membrane wall heat exchanger 6 is as follows: figure 2 shown. The membrane wall heat exchanger 6 provides heat for the sludge by exchanging heat with the hot fluid, so that the temperature of the sludge reaches the reaction condition, and a thermal hydrolysis reaction occurs; the membrane wall heat exchanger 6 is close to the inner wall of the cylinder 8, increasing the memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com