A New Type of Rotating Liquid Whistle Cavitation Generator

A generator, a new type of technology, applied in liquid-liquid heterogeneous reaction and liquid-liquid mixing, wastewater treatment, cavitation fields, can solve the problems of low energy utilization rate, difficult large-scale application, unable to achieve constant temperature function, etc., to achieve Improve cavitation efficiency and cavitation intensity, enhance ultrasonic cavitation effect, and improve energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

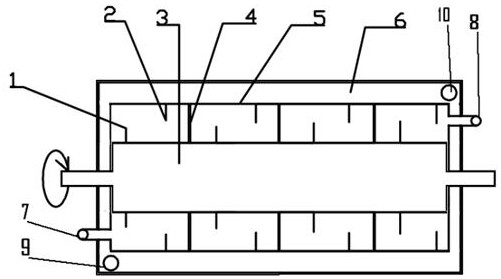

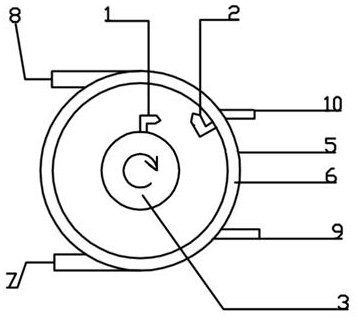

[0023] A new type of rotating liquid whistle cavitation generator, comprising a coaxially arranged rotor 3 and a housing 5, the rotor 3 is rotatably arranged in the housing 5 through a rotating shaft, and one end of the housing 5 is provided with a feed liquid inlet 7, The other end of the housing 5 is provided with a feed liquid outlet 8; the outer side of the housing 5 is provided with a heat exchange interlayer 6, one end of the heat exchange interlayer 6 is provided with a heat exchange fluid inlet 9, and the other end of the heat exchange interlayer 6 is provided with a The heat exchange fluid outlet 10 and the heat exchange interlayer 6 can be connected to a constant temperature tank, thereby controlling the stability of the temperature outside the housing 5 . The temperature control of the liquid in the casing 5 can be realized through the heat exchange interlayer 6 .

[0024] A plurality of rows of primary reeds 1 are evenly spaced along the outer wall of the rotor 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com