Semiconductor manufacturing device

A technology for manufacturing devices and semiconductors, which is applied in the field of semiconductor manufacturing devices and can solve problems such as complex manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

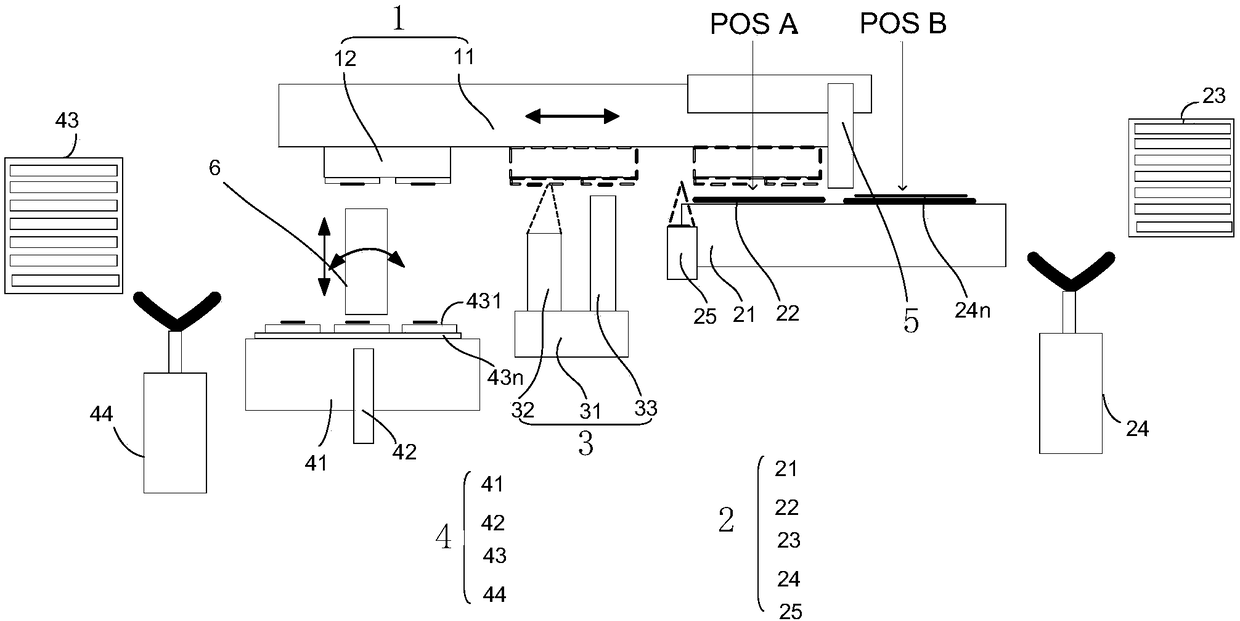

[0023] refer to figure 1 , which is a schematic diagram of the semiconductor manufacturing device provided in Embodiment 1, such as figure 1 As shown, the semiconductor manufacturing device includes: a chip supply module 4, a chip picker 6, a chip transfer module 1, a carrier board supply module 2 and a package module 5, and the chip transfer module 1 includes a transfer module capable of absorbing a plurality of chips 431. stage 12, the carrier board supply module 2 includes a carrier board 22 and a carrier board moving table 21; the chip picker hand 6 picks up a chip from the chip supply module 2 and transfers it to the transfer station 12, and the transfer station 12 carries a plurality of chips and then moves to the bonding station. The carrier board moving table 21 carries the carrier board 22 and then moves to the bonding station. The transfer table 12 is opposite to the carrier board moving table 21 moving, bonding 431n the plurality of chips to the carrier 22 to for...

Embodiment 2

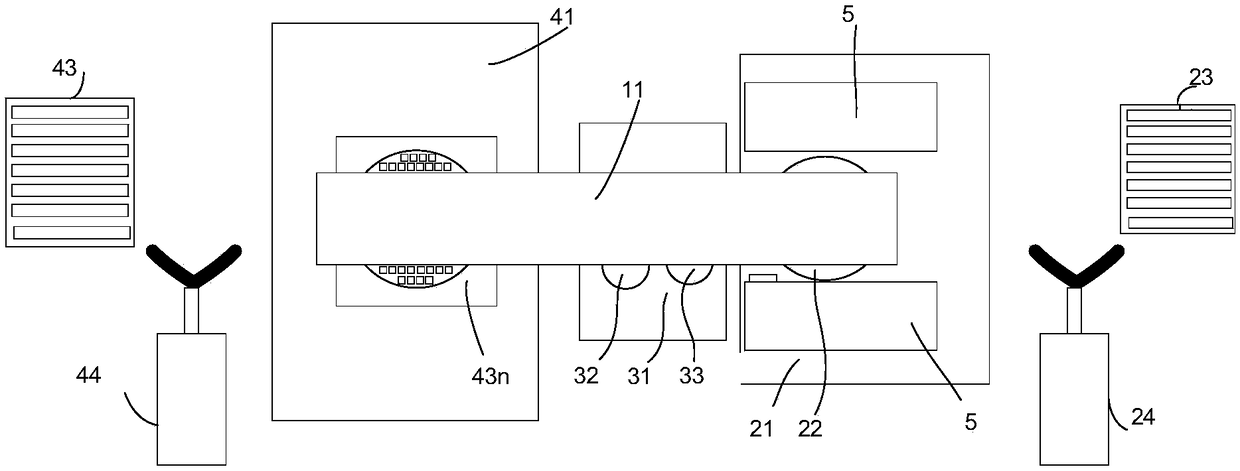

[0031] see Figure 4-Figure 5 , in this embodiment, chip bonding and packaging are not completed in the same step and station, such as Figure 4 As shown, the chip 431 is firstly bonded to the carrier 22 at the POS C station, and then packaged at the POS D station.

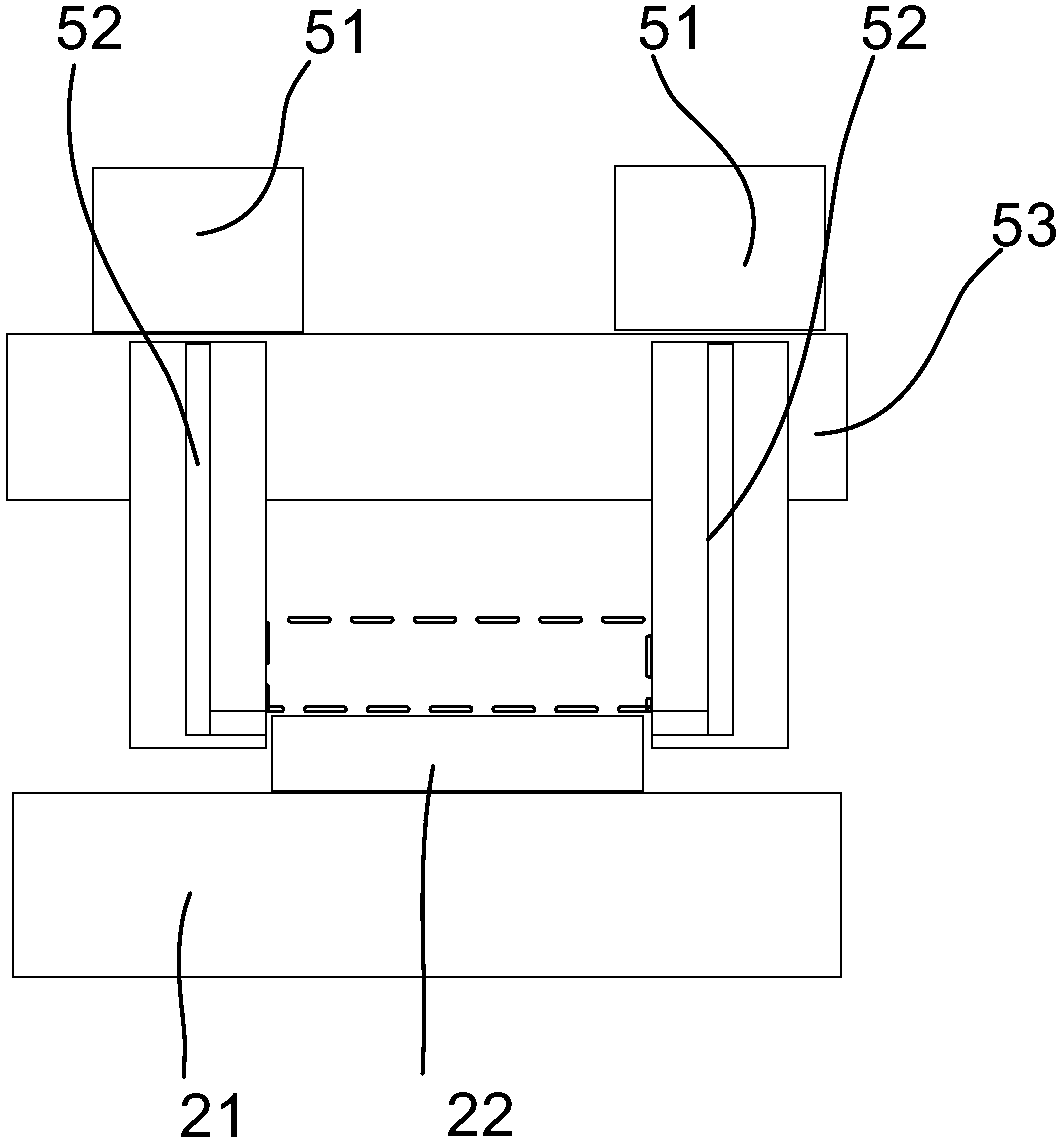

[0032] see Image 6 , in this embodiment, the packaging module 5 not only has a packaging material supply unit 51, an injection molding unit 52 and a packaging motion table 53, but also includes a glue storage supply unit 54 and a glue application unit 55. Preferably, the storage There may be multiple glue supply units 54 and glue application units 55 to increase glue application efficiency. The glue supply unit 54 supplies the bonding glue to the gluing unit 55, and the gluing unit 55 coats the surface of the carrier plate 22 with bonding glue. Preferably, the gluing unit 55 can be used for bonding The glue is pressurized to better control the flow rate of the glue.

[0033] Specifically, the carrier board 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com