Climbing steel platform supporting devices and using method thereof

A supporting device and steel platform technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of climbing steel columns such as difficulty in installation, complex shape, and large changes from top to bottom, so as to avoid Potential danger of instability, fast assembly and disassembly, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

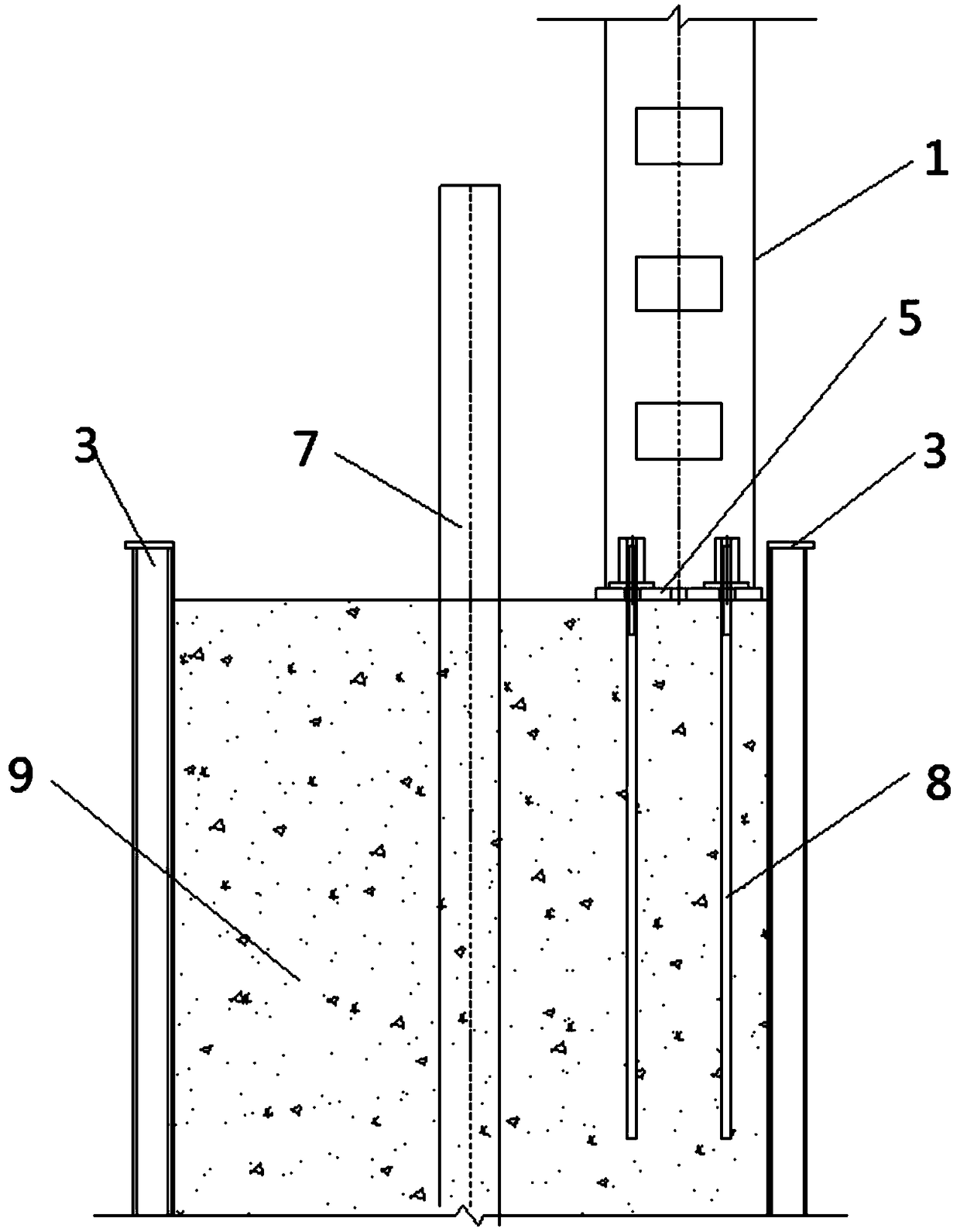

[0041] refer to figure 1 , this embodiment provides a climbing steel platform support device installed on the top of the wall 9, the wall 9 embedded with prefabricated bolts 8, the prefabricated bolts 8 protrude from the top of the wall 9, the climbing steel platform supports The device includes a climbing steel column 1, which is arranged on the top of the wall body 9 and is fixedly connected with the wall body 9 through prefabricated bolts 8.

[0042]In the supporting device for a climbing steel platform in this embodiment, the climbing steel column 1 is fixedly connected to the wall 9 through prefabricated bolts 8, which solves the problem of fixed installation of the climbing steel column and avoids the hidden danger of instability during the climbing of the climbing steel platform. In addition, the climbing steel column 1 is easy to install, and the climbing steel column 1 can be easily dismantled after the construction is completed, thereby realizing the rapid assembly, ...

Embodiment 2

[0046] refer to figure 1 , the present embodiment provides a method for using the climbing steel platform support device described in Embodiment 1, and the technical solution is as follows:

[0047] A method of using the above-mentioned climbing steel platform support device, comprising the following steps:

[0048] In the first step, the top surface of the wall 9 is smoothed;

[0049] In the second step, the climbing steel column 1 is fixedly arranged on the top of the wall 9;

[0050] In the method of using a climbing steel platform support device in this embodiment, the climbing steel column 1 is fixedly connected to the wall body 9 through prefabricated bolts 8, which solves the problem of fixed installation of the climbing steel column and avoids instability during the climbing of the climbing steel platform Hidden danger. In addition, the climbing steel column 1 is easy to install, and the climbing steel column 1 can be easily dismantled after the construction is comp...

Embodiment 3

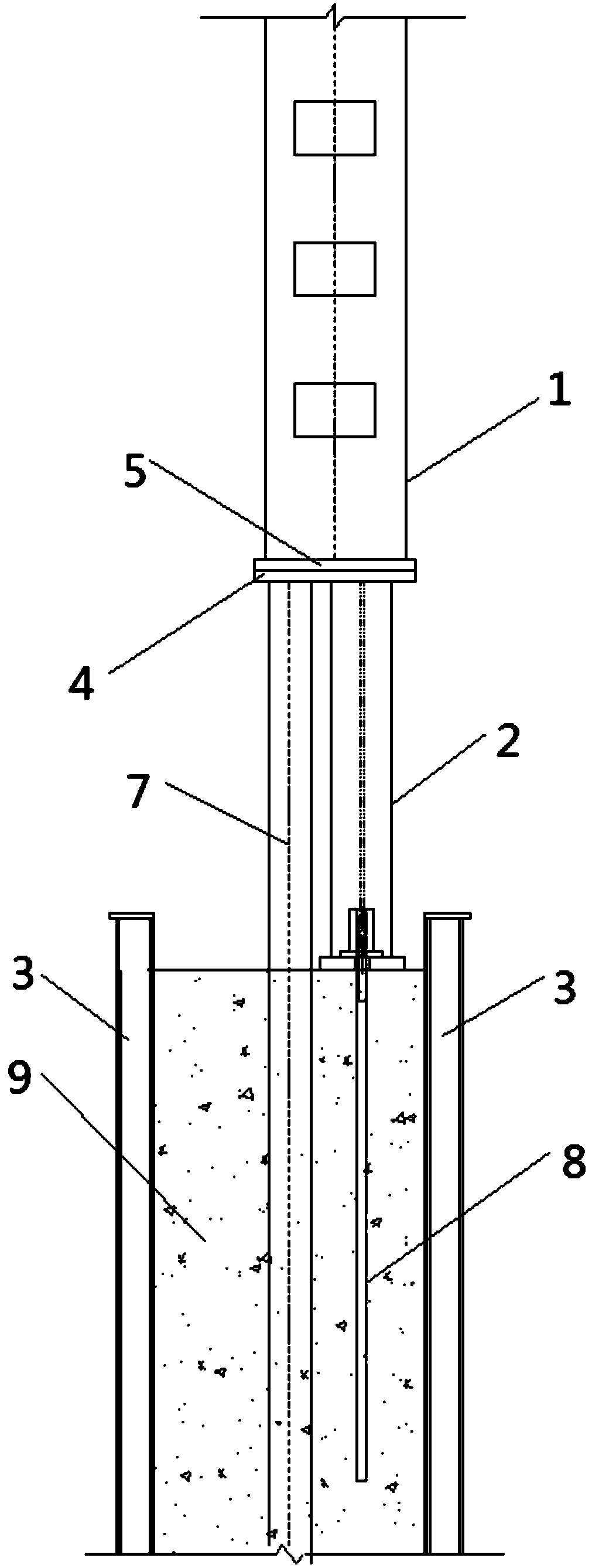

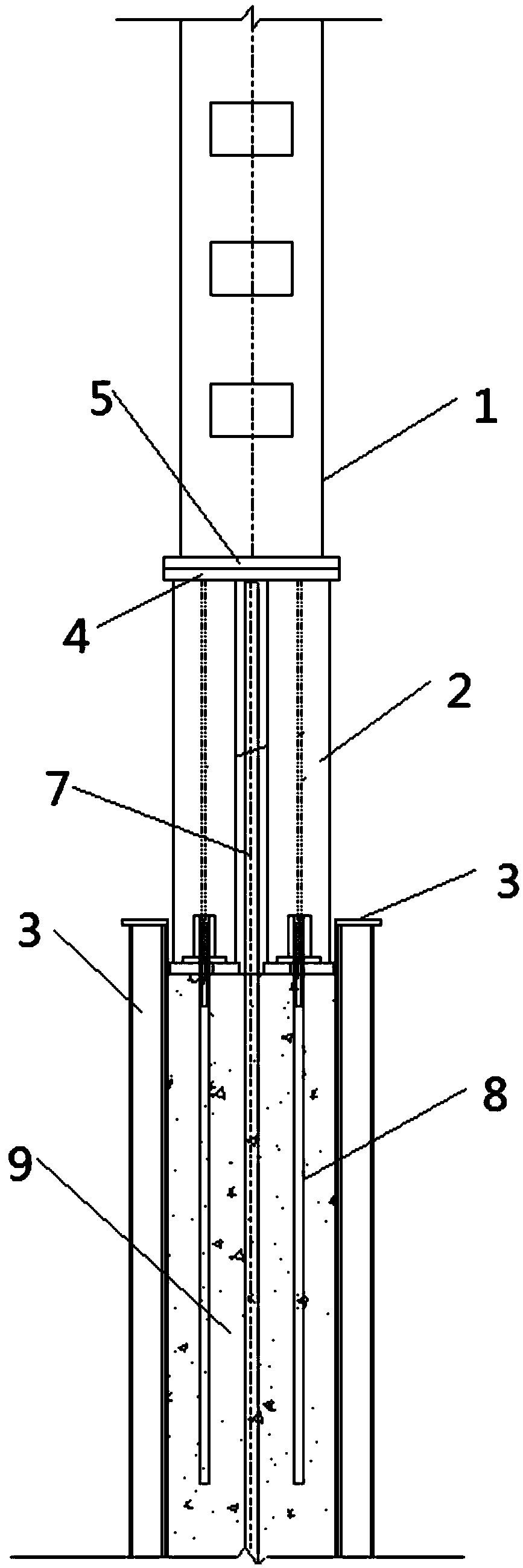

[0052] refer to figure 2 The technical solution of a climbing steel platform support device provided in this embodiment is as follows, a climbing steel platform support device is installed on the top of a wall 9, and prefabricated bolts 8 and shear steel plates 7 are embedded in the wall 9, The prefabricated bolts 8 and the shear steel plates 7 protrude from the top of the wall 9, and the climbing steel platform support device includes a climbing steel column 1 and a shaped steel leg 2, and the shaped steel leg 2 is arranged on the top of the wall 9 and The prefabricated bolts 8 are fixedly connected to the wall 9, the height of the shaped steel leg 2 is the same as that of the shear steel plate 7, and the climbing steel column 1 is fixedly installed on the upper part of the shaped steel leg 2 and the shear steel plate 7.

[0053] A climbing steel platform supporting device of this embodiment fixes the climbing steel column 1 on the upper part of the shaped steel leg 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com